Synchronize Feeder Line Materials with the Main Production Line for Flow Schedule Execution

In flow manufacturing environments that apply lean principles, feeder lines are often employed to deliver raw materials and subassemblies directly to the main production line workstations when they are required by the production of the parent assembly. The timing is driven by the line rates and flow schedules for a set of products.

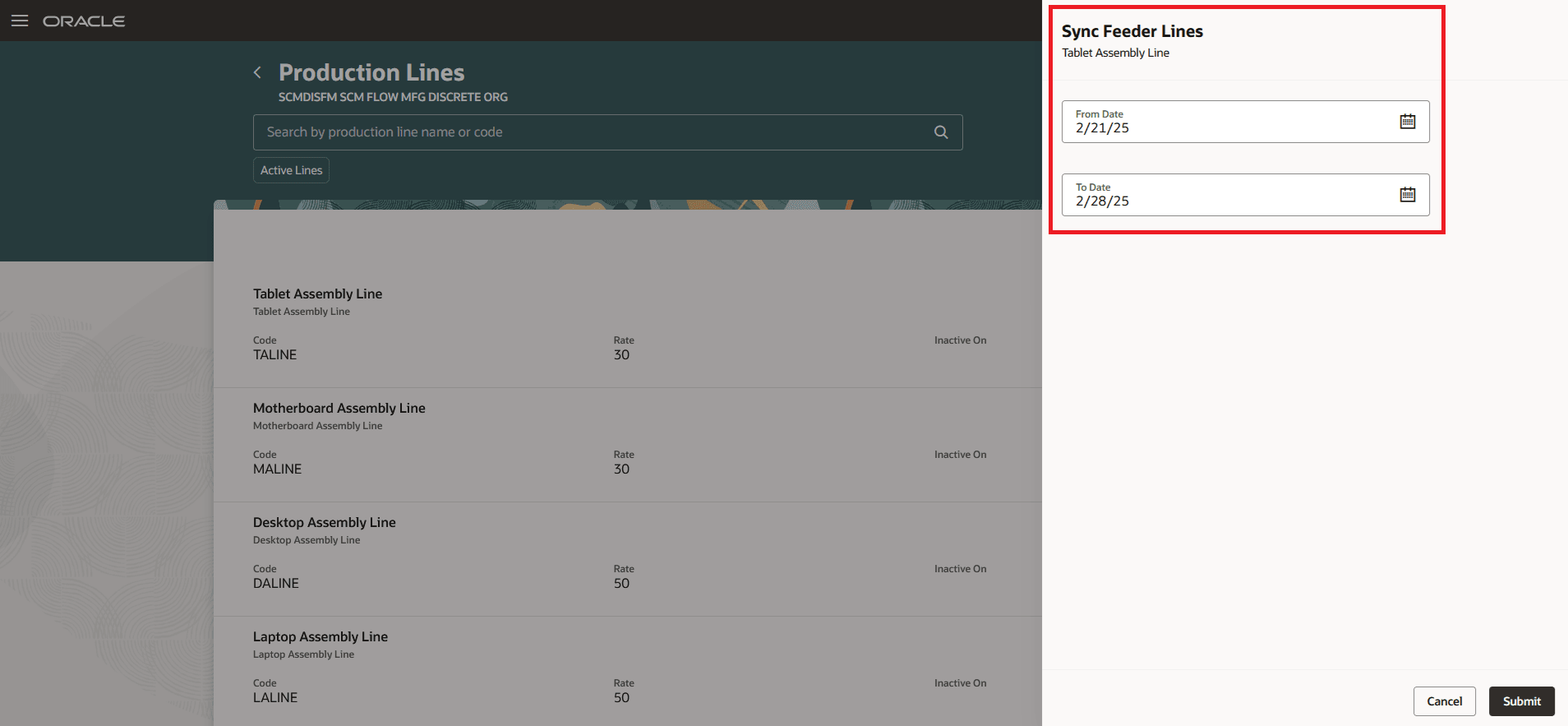

You can now synchronize feeder lines with the main production line by creating child flow schedules for the dependent demand derived from the parent flow schedules of the parent assemblies. In the Redwood page for Manage Flow Schedules, you can invoke the Sync Feeder Lines action for a parent production line to create the flow schedules for feeder lines based on the specified date range.

Synch Feeder Line with Main Line for a Date Range

The scheduled process for feeder line synchronization initially determines which items to schedule based on the pull components with their own work definitions. The logic then generates subassembly schedules according to the sequence of the parent assembly schedules to be produced on the line. The need by date of the child flow schedule on a feeder line is determined by taking into consideration the parent assembly flow schedule slot for a specific day, the total number of operations for its work definition, the operation at which the component is needed, and the line capacity of the parent production line.

For example, the tablet assembly line makes a set of tablet products. The feeder line synchronization logic identifies the flow schedules of the tablets on the tablet assembly line and generates the flow schedules for the motherboards that come from a feeder line.

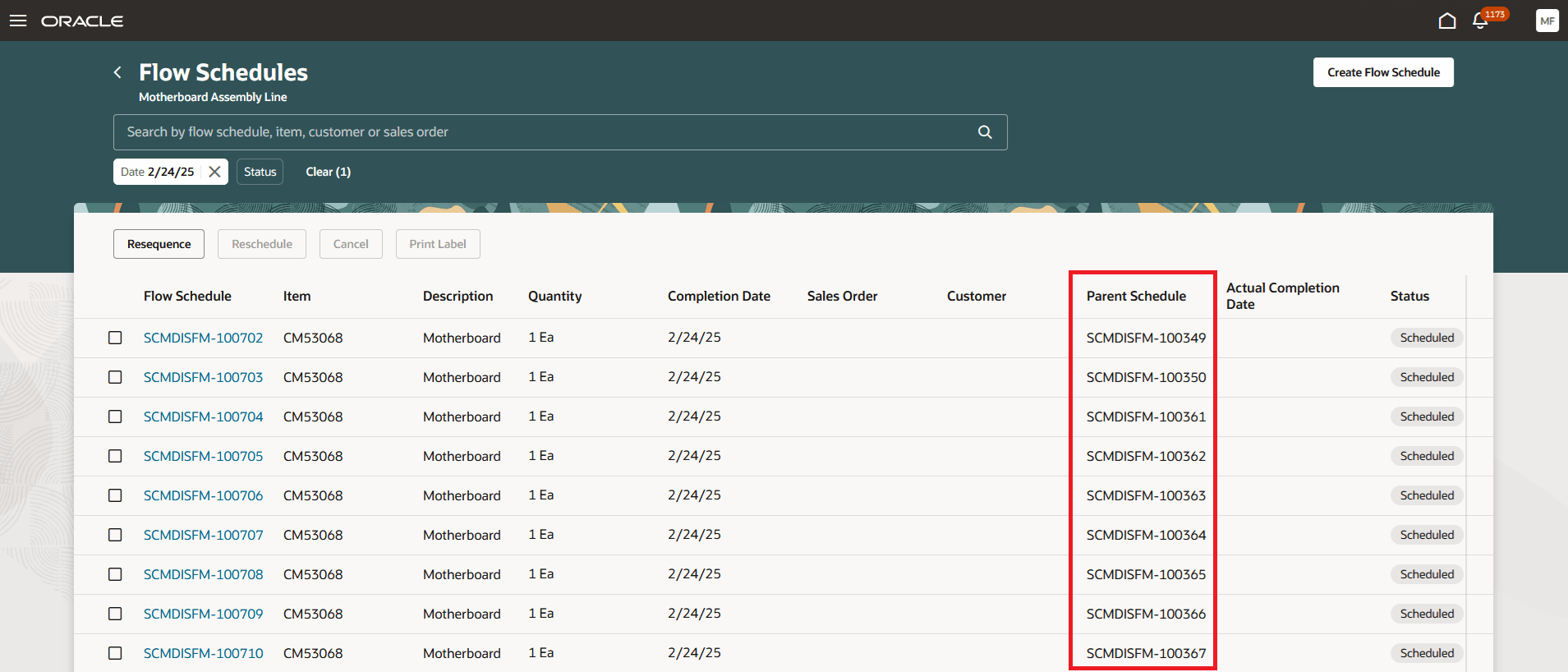

You can also view the parent flow schedule for a child flow schedule in the Flow Schedules page.

Review Parent Schedule for a Child Flow Schedule

Feeder line synchronization delivers materials just-in-time to the main production line, reducing the risk of delays and minimizing the need for buffer stock.

Here's the demo of these capabilities:

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- As a best practice, you can re-run the feeder line synchronization scheduled process to re-create the flow schedules for subassemblies after resequencing or rescheduling a flow schedule of the parent assembly. You can manually reconcile any resequencing or rescheduling changes to subassembly flow schedules that impact the parent flow schedule.

- You can run the scheduled process for Sync Feeder Lines from the Production Lines UI or through the Scheduled Processes quick action.

Key Resources

- Watch the Synchronize Feeder Line Materials with the Main Production Line for Flow Schedule Execution demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges can use this feature:

- Manage Flow Schedules ( WIP_MANAGE_FLOW_SCHEDULES)

This privilege was available prior to this update.

- Sync Feeder Lines (WIP_SYNC_FEEDER_LINES)

This privilege is new in this update.