Monitor Equipment Condition Using Tracked Sensor Values

When an asset produces an error or a failure state, maintenance teams must create maintenance work orders to restore the asset. With this update, both failure events and operational parameter values from connected equipment can be used to automatically generate a condition-based maintenance work order corresponding to those events. This capability enables the contextualized automated generation of maintenance work orders specific to equipment conditions that allow proactive planning of maintenance activities and minimize disruption to operations.

This update lets you:

- Configure operational parameters sent by connected assets to capture those parameters.

- Configure operational rules, which evaluate received operational parameters from connected assets.

- Contextualize operational rules to a group of assets: items, item categories, or all assets.

- Contextualize operational rules to location or operating organizations.

- Create work orders on the first occurrence or only if an issue persists for a given duration to ignore sporadic events.

- Configure work order descriptions to provide better information to the maintenance team.

- Use maintenance programs with condition codes configured in operational rules. This allows to use maintenance programs with work requirements defined for an asset or group of assets, use one or more condition codes, and determine work definitions to use when creating the work order.

Operational rules with operational parameters now include these additional features:

- Event Ingestion: Connected assets can now send operational parameters. These new events contain the asset number, the time it occurred, and a set of operational parameter values pertaining to the event.

- Evaluation Criteria: Use operational rules to evaluate incoming operational parameters. When you configure an operational rule, it can now be selected if it applies to all connected assets, individual assets, items or item categories.

- Contextualization: Configure to the location or operational organization the rules apply to. Operational rules can be configured to apply to all the connected assets, items, or item categories.

- Outcome: Outcome of an operational rule, which creates a Maintenance work order can now use configurable descriptions. Work orders can be created on the first occurrence or if an issue persists for a given duration.

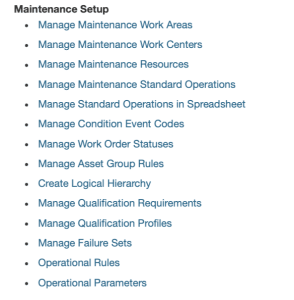

Use the new Operational Parameters task in the Maintenance Management work area, highlighted in the screenshot below, to create operational parameters used in operational rules for assets.

The Operational Parameters task under Maintenance Setup

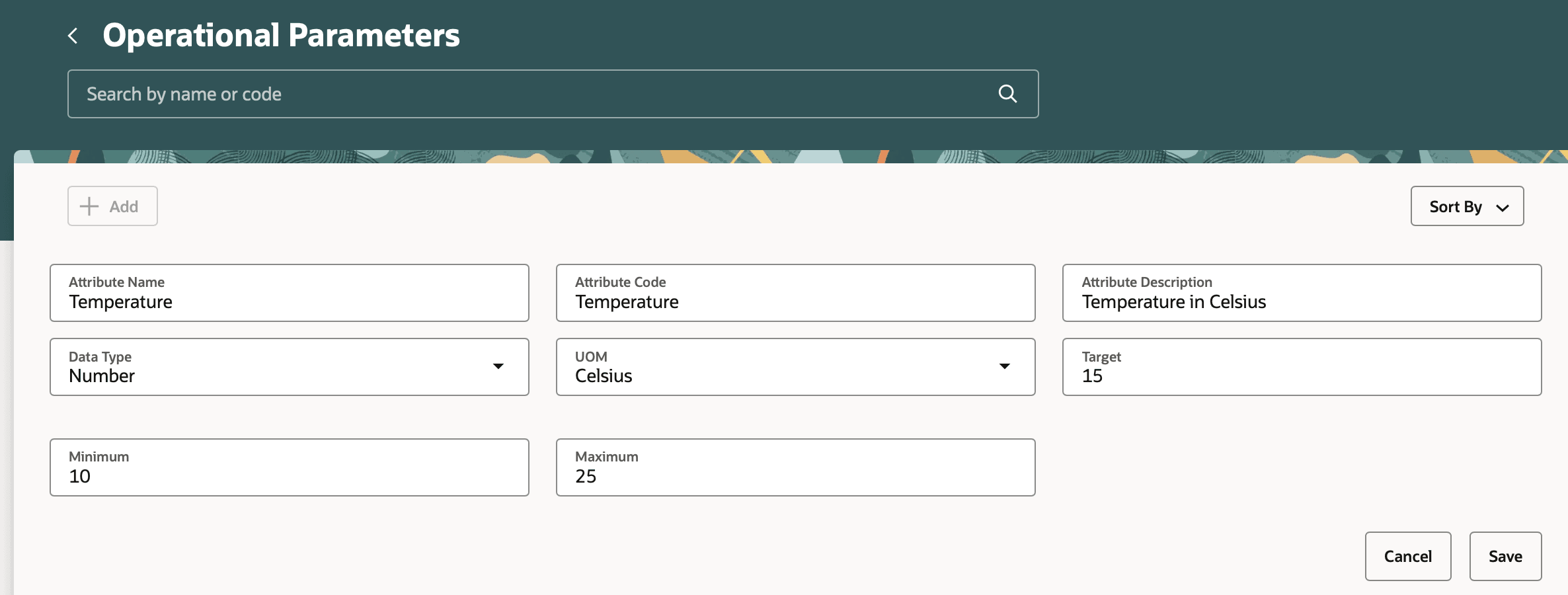

You can also create operational parameters, which can be used in operational rules later. Here's a screenshot of the Operational Parameters page where you enter name, code, description as well as data type, and a unit of measure. The fields Target, Minimum, and Maximum are optional and won't be used in operational rules.

The Operational Parameter Setup

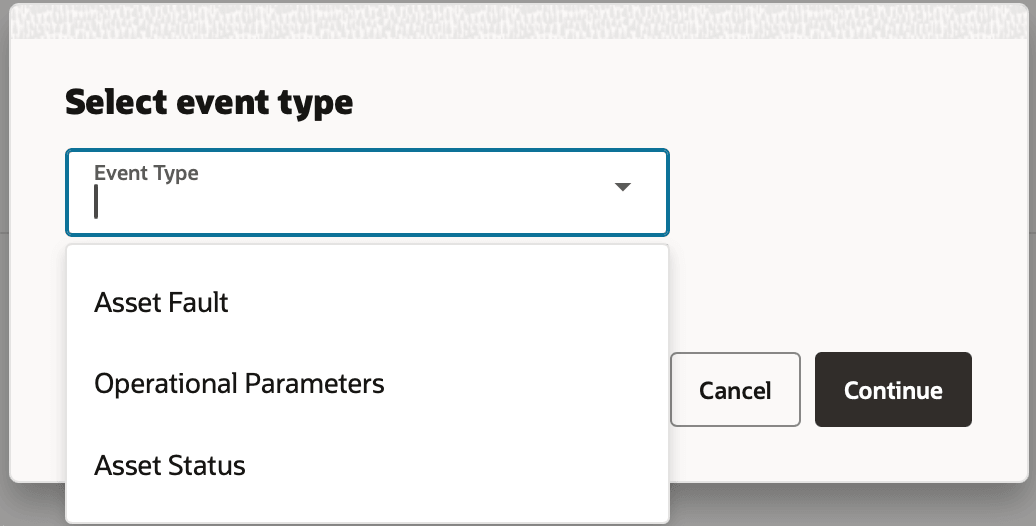

As a next step, use the Operational Rules task in the Maintenance Management work area to create rules using operational parameters. Here's a screenshot that shows selecting Operational Parameters as the event type.

Screenshot showing Operational Parameters under Select event type

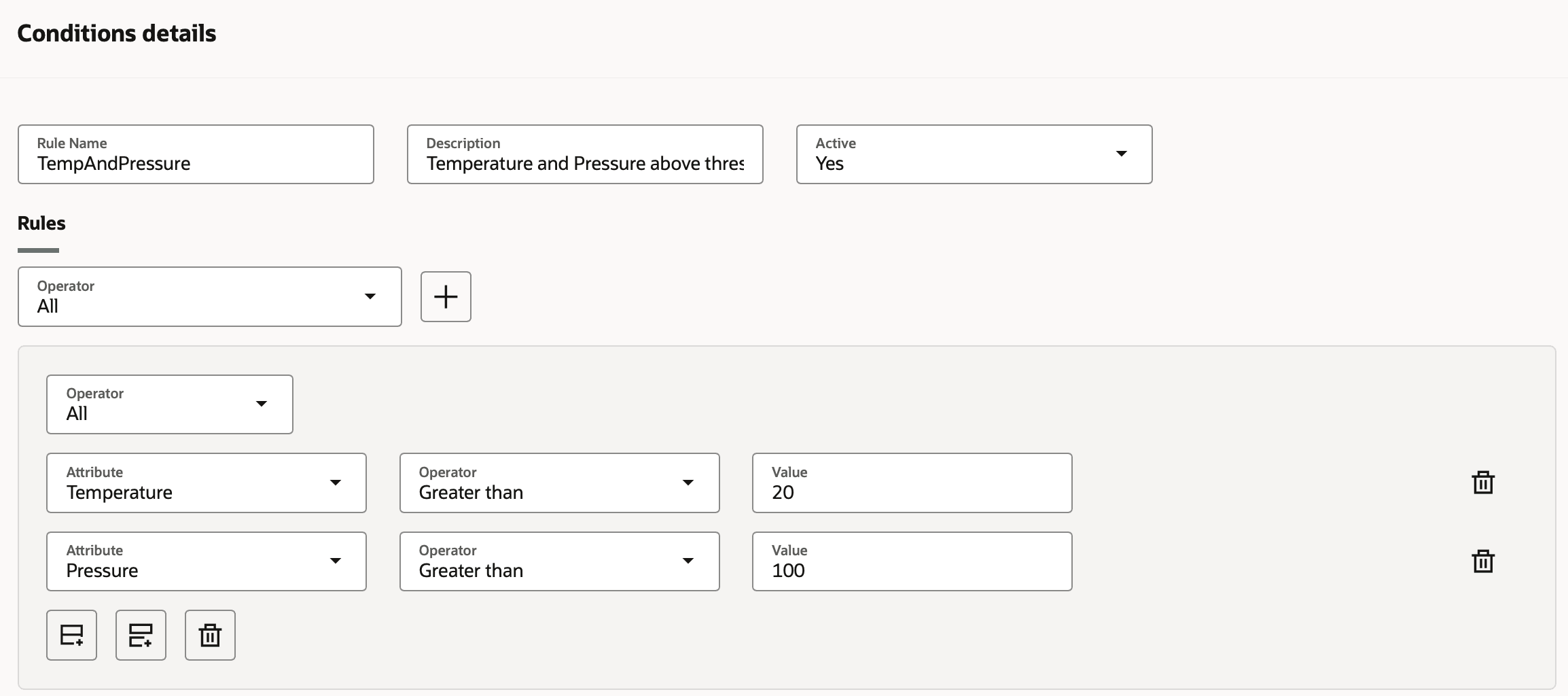

Operational Parameters created before can now be evaluated in conditions. Here's a screenshot of the Condition details page that shows an example condition where the temperature greater than 20 and pressure greater than 100 is set as above threshold thereby checks for threshold violations.

Screenshot showing the Conditions Details Page with Conditions and Rules

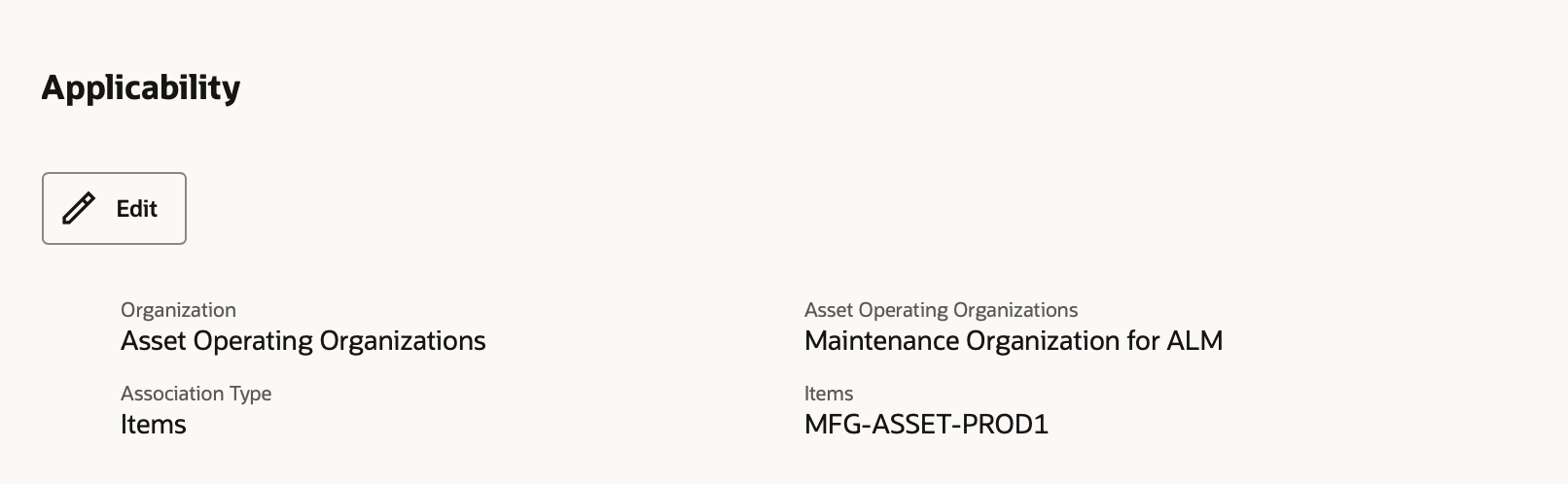

By default, Operational Rules can be applied to all assets and organization. Alternatively, Operational Rules usage can be restricted to certain organizations and to a certain groups of assets. In the Applicability section shown in the screenshot below, you can select Operating Organizations or Location/Manufacturing Plant Organizations as well as groups of assets such as Asset items or Asset item category.

Screenshot showing Applicability section for Operational Rules

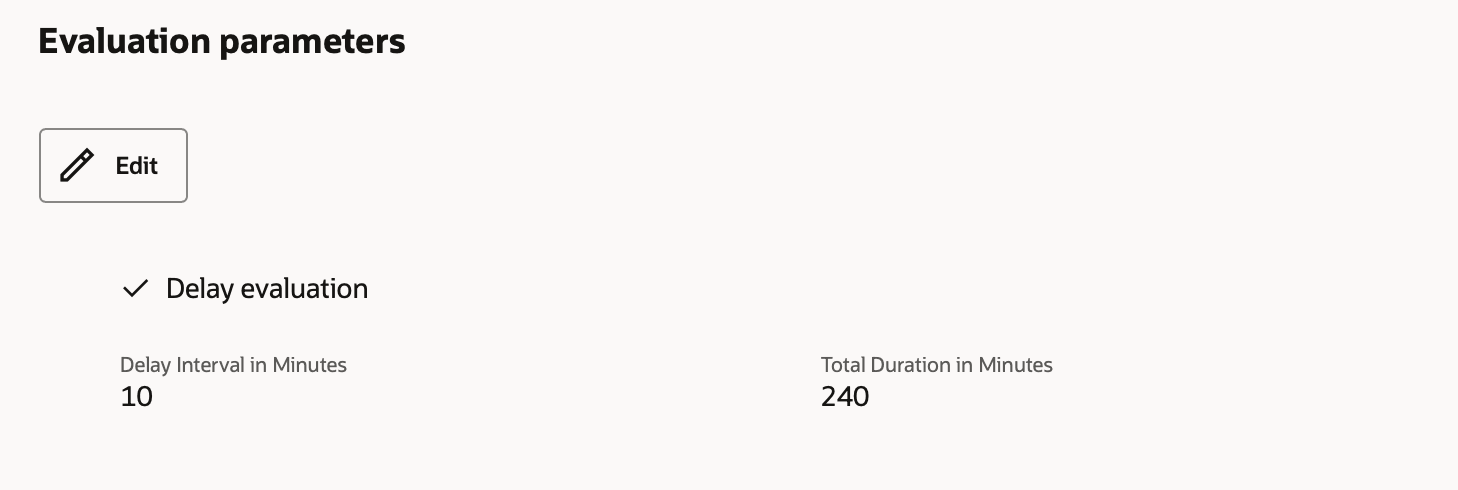

By default, Maintenance work orders are created on the first occurrence the conditions are met.

In some use cases, faults or operational parameters violations can occur sporadically. This is typically related to noise or temporary situations. For example, during startup sequence of an asset. If this situation doesn't persist it's considered harmless and there's no need to create a Maintenance work order. To cover such a situation, you can set evaluation parameters. Here's a screenshot of Evaluation parameters where events that occur longer than 10 minutes create a work order, as specified in the delay interval. Total duration specifies the interval during which such events are considered to belong together. If new occurrences happen after the total duration it's considered a new situation, such as a new startup sequence and not be counted related to the initial occurrence.

The Evaluation Parameters Section

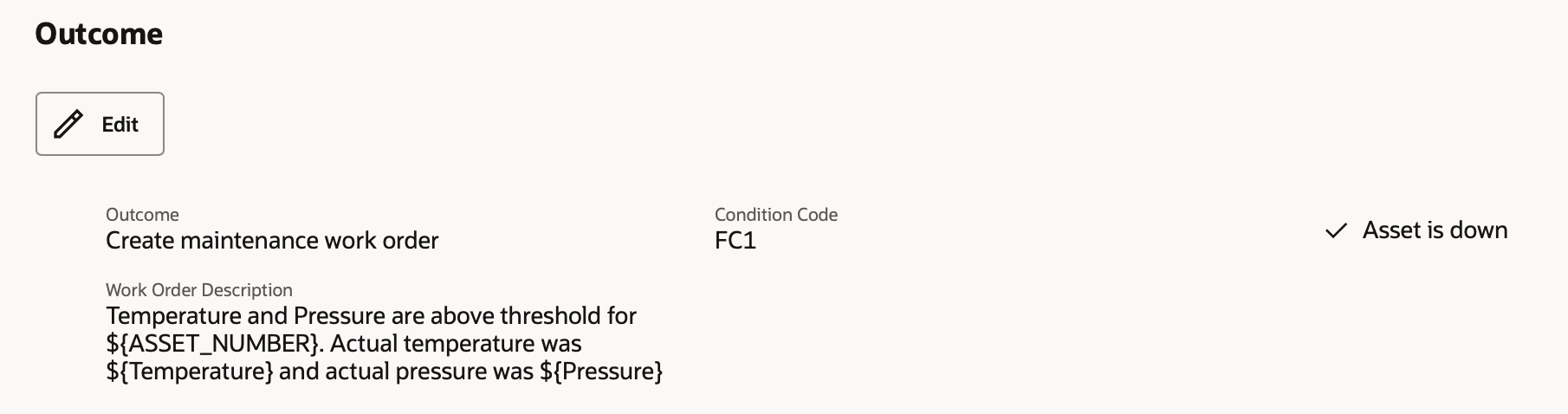

Work order descriptions can be configured. Description templates can contain references to Operational Parameters as well as context parameters. Context parameters can be:

- RULE_NAME: rule name of the evaluated rule

- RULE_CODE: rule code of the evaluated rule

- ASSET_NUMBER: asset number of the asset which sent the event

- FAULT_CODE: fault code received from the asset

Here's a screenshot of the Outcome page that shows an example outcome where the asset number as well as two operational parameters for pressure and temperature are replaced by the actual parameters, when a work order is created.

The Outcome Section with Work Order Description

Condition codes can be specified explicitly for a certain outcome. These explicit condition codes are used when the work order is created and to identify maintenance programs using these condition codes. In the example above, the condition code used for the Maintenance work order creation is FC1.

Asset availability is an important performance indicator for the maintenance function. Condition-based maintenance enables maintenance teams to proactively respond to critical issues and plan maintenance to minimize disruption to asset operations or production. Operational Parameters such as pressure, temperature, and vibration are monitored to check if there are underlying conditions that may need attention. By using thresholds against the tracked operational parameters, maintenance work orders can be generated for values outside of tolerance.

Here's the demo of these capabilities:

Steps to Enable

This feature requires additional services, SCM Core Service-Smart Operations, to be provisioned on your instance. To enable this service, log a service request:

- Select Product Module: Oracle Maintenance Cloud Service

- Select Category: Maintenance Work Orders

- Select Subcategory: Maintenance Work Orders

- Select Component: Installation Issue (INSTALL)

- Select Severity: 3-Minimal Loss of Service

- Copy and paste this text into description area of the SR: Enable the SCM Core Service-Smart Operations

This service can be enabled on instances that are available on Oracle Public Cloud regions.

Tips And Considerations

- You need to convert the connected asset events received via industrial communication protocols into a REST payload that Fusion Maintenance Cloud can ingest and take actions on. See this document to learn more about the accepted payload specifications: REST API for Oracle Fusion Cloud SCM.

- Operational Parameter events need to be ingested using the operational parameter codes as configured.

- This feature isn't meant to accept time series data. It's assumed that the high frequency data will be pre-screened and condensed by an external Industrial IoT framework.

Access Requirements

Users need this privilege to create, edit, delete, or view operational rules:

- Manage Operational Rules (SMO_MANAGE_OPERATIONAL_RULES_PRIV): For Create, Read, Update, Delete operations.

- View Operational Rules (SMO_VIEW_OPERATIONAL_RULES_PRIV): For Read Only operation.

- Access HCM Common Components (HRC_ACCESS_HCM_COMMON_COMPONENTS_PRIV)

- Manage HCM Rules (HRC_MANAGE_HCM_RULES_PRIV)

Users need this privilege to create/edit/delete/view Operational Parameters:

- Manage Operational Parameters (SMO_MANAGE_OPERATIONAL_PARAMETERS_PRIV): For Create, Read, Update, Delete operations.

- View Operational Parameters (SMO_VIEW_OPERATIONAL_PARAMETERS_PRIV): For Read Only operation.

- Access HCM Common Components (HRC_ACCESS_HCM_COMMON_COMPONENTS_PRIV)

- Manage HCM Rules (HRC_MANAGE_HCM_RULES_PRIV)

Users need this duty role to manage Operational Rules:

- Access to SMO Rules Management (ORA_DR_SMO_MANAGE_OPERATIONAL_RULES_MNT_DUTY)