Redwood: Review Supply Allocation

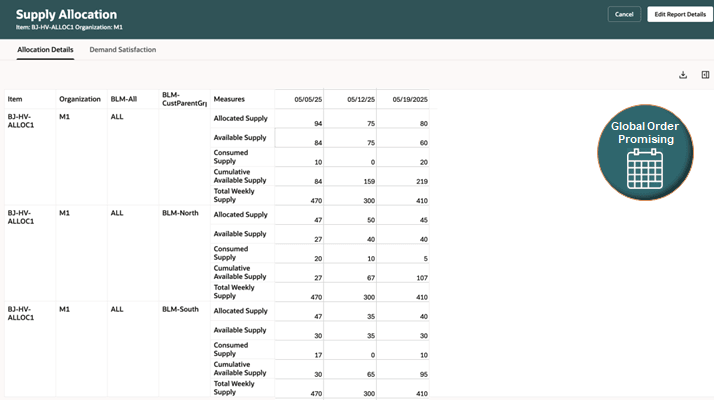

Review the total and remaining supply that's allocated each week for the items that you select. You can also view the expected fill rate and on-time percentage.

The supply that's available for an allocated item might not meet demand and that might affect the requested quantity and timing. You can now access a report that illustrates the total amount that's assigned to each node in the allocation hierarchy, the remaining quantity that customers can order each week, and other related measures. The report also summarizes the amount of demand that's scheduled on time and the fill rate. Use these details to explain delay or adjust quantity so you can avoid allocation limits.

Try It:

- Go to the Order Management work area and open a sales order that's in Processing status.

- Select an order line, then click More Actions > Check Availability.

Here's another way:

Start at your home page, then click Order Management > Show More > Supply Allocation.

Examine the report:

The report displays supply allocation data for an item-organization. It includes data for a variety of measures:

|

Measure |

Description |

|

Allocated Supply |

Supply allocated to the allocation node during the week according to an allocation rule. |

|

Available Supply |

Allocation that's available on a node. It's the allocated supply minus the consumed supply. |

|

Consumed Supply |

Allocated supply that other order lines have already consumed. |

|

Cumulative Available Supply |

Allocation that's still available for each week on a cumulative basis. |

|

Total Weekly Supply |

Total supply for the item and organization for each week without referring to an allocation node. |

|

Manual Allocation |

Quantity of supply that's allocated to an allocation node. |

|

Allocation from Redeployment |

Supply that promising redeployed from other allocation nodes. |

|

Supply Allocated for Redeployment |

Allocated supply for the node minus the supply that's protected according to the value in the Stealing Protection Percentage attribute on the allocation rule. |

|

Supply Allocated to Child Nodes |

Allocation to child nodes. |

|

Gross Allocated Supply |

Supply that promising allocated to the parent node and its children. |

|

Gross Allocation from Redeployment |

Total quantity of supply that promising redeployed for an allocation node and its children. The report displays:

|

|

Gross Available Supply |

Allocation that's available for the parent node and its children. |

|

Gross Consumed Supply |

Allocation consumed at the parent node and its children. |

|

Gross Cumulative Supply |

Cumulative allocation that's available at the parent node and its children. |

|

Total Supply |

Total supply that's available. Use it to get the history about shipped sales order. |

|

Consumed Supply by Shipped Orders |

Allocated supply that shipped orders consumed at a node. Use it to get the history about shipped sales order. |

|

Gross Consumed Supply by Shipped Orders |

Allocation that promising consumed at the parent node and its child nodes for orders already shipped. Use it to get the history about shipped sales order. |

The report displays data for demand satisfaction measures:

|

Measure |

Description |

|

Demand Quantity |

Total quantity for the demand at an allocation node for each week. |

|

Scheduled On Time Percentage |

A percent that measures the number of sales orders out of the total number of orders for one week. Displayed as the percent of sales orders where:

Or

|

|

Scheduled Fill Rate Percentage |

A percent that measures the demand out of the total demand for one week. Displayed as a percent of sales orders where:

|

|

Demand Revenue |

Amount of revenue from the demand for the requested dates during the week. |

|

Scheduled On Time Revenue |

Amount of revenue from the demand for the requested dates during the week where:

or

|

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- You can use this report only for items where you have set their ATP mode to Supply Chain Search, and where you have enabled the Respect Allocation Constraints attribute in your ATP rule. See Set Attributes on Your Supply Chain.

- You can't use this report for items where you set the ATP mode to Infinite Availability or to Lead-Time Based.

- The allocation set ups in the allocation rule rely on the Attribute-Based Planning feature.

- This report displays allocation details for each week according to allocations made from Monday through Sunday. You can specify only Monday as the start date.

Key Resources

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- View Supply Allocation Report (MSP_VIEW_SUPPLY_ALLOCATION_REPORT_PRIV)

This privilege was available prior to this update.