Configure The Starting Date for Calculations of Average Daily Demand for Days of Cover Safety Stock

Configure The Starting Date for Calculations of Average Daily Demand for Days of Cover Safety Stock

Many enterprises use the days of cover safety stock policy to manage unexpected demand and supply changes. The calculation for days of cover uses the average daily demand as the primary input. In some enterprises, the computation is highly sensitive to the starting date that’s used to compute the average daily demand due to rapid changes in demand. This update enables you to set a parameter to use the next time bucket as the starting point for the calculations, as opposed to the default of the current bucket.

The safety stock for days of cover is calculated as average daily demand multiplied by days of cover. Currently, the average daily demand is determined for each bucket based on the demand period. When there’s a spike in demand for a specific time bucket, the average daily demand calculation for that bucket also includes the demand for that bucket, leading to an inflated safety stock and, consequently, a higher projected available balance (PAB) for that period. Because demand in subsequent periods is low, this excess PAB must be carried forward, increasing the projected inventory cost over the next few weeks.

Background

Days of cover is based on a moving average demand and a user-specified target for days of cover.

To set up items to use the days of cover method, set the following three item-organization attributes on the Manage Items page in the Product Information Management work area:

- Safety Stock Planning Method = Days of Cover

- Demand Period = User-defined value that specifies the period of demand and that’s used to calculate the average daily demand in days.

- Days of Cover = User-defined value that specifies how many days of safety stock are needed and that’s calculated based on the average daily demand. The value can be a fractional value.

Average Daily Demand: Default Behavior

Oracle Fusion Cloud Supply Planning calculates the actual days of cover safety stock level based on the following:

Average Daily Demand = Sum (Demands for Demand Period days) / Demand Period days

- Demands are sales orders, forecasts, manual demands, and dependent demands.

- The Demand Period days value is evaluated in working days and starts from the current bucket.

- Safety Stock for day x = Average Daily Demand for day x multiplied by Days of Cover.

Shifted Average Daily Demand: Optional New Behavior

Shifted Average Daily Demand = Sum (Demands for the Demand Period days) / Shifted Demand Period days

- Demands are sales orders, forecasts, manual demands, and dependent demands.

- The Shifted Demand Period days value is evaluated in working days and starts from the next planning bucket after the current bucket.

- Safety Stock for day x = Shifted Average Daily Demand for day x multiplied by Days of Cover

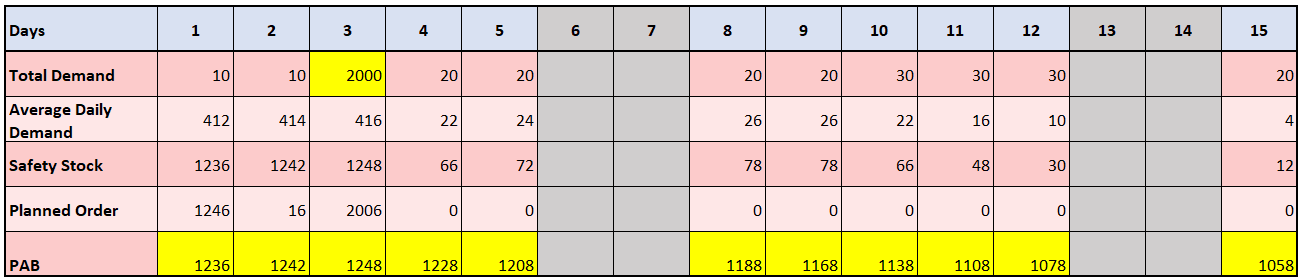

Example 1.1: Average Daily Demand in Daily Buckets - Default Behavior

In this example, there’s a 5-day work week, Demand Period = 5 days, Days of Cover = 3 days, and Plan Horizon = Day 15.

In the default behavior, the Average Daily Demand is calculated using the current bucket as the starting point for the Demand Period.

Average Daily Demand Based on the Current Bucket

As a result of unusually high demand on Day 3, the Average Daily Demand for Day 3 is calculated to be (2000 + 20 + 20 + 20 + 20)/5 = 416, and the safety stock is therefore 3 × 416 = 1248, which results in a large planned order on Day 3. This causes PAB to remain high to the end of the planning horizon.

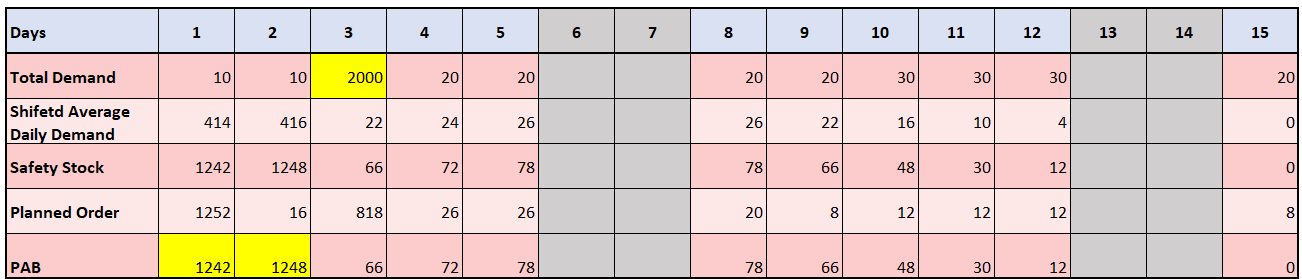

Example 1.2: Shifted Average Daily Demand in Daily Buckets - Optional New Behavior

In this example, there’s also a 5-day work week, Demand Period = 5 days, Days of Cover = 3 days, and Plan Horizon = Day 15.

But with the new behavior, the Shifted Average Daily Demand is calculated using the next bucket as the starting point for the Demand Period.

Shifted Average Daily Demand That Starts Based on the Next Bucket

Even with the unusually high demand on Day 3, the Average Daily Demand for Day 3 is calculated to be (20 + 20 + 20 + 20 + 30)/5 = 22, and the safety stock is therefore 3 × 22 = 66, which results in a smaller planned order on Day 3 compared to the scenario where the Average Daily Demand was calculated based on the current bucket as the starting bucket for the Demand Period. The PAB on Day 3 is reduced because of the smaller planned order on Day 3, and it continues to be much smaller than the previous scenario, from Day 4 to the end of the planning horizon.

The Shifted Average Daily Demand shown in the preceding table is different from the Average Daily Demand measure. It’s created for explanation purposes only, and it’s not a measure that can be shown in the material plan. The Shifted Average Daily Demand is shifted by one bucket to the left compared to the Average Daily Demand measure.

The Average Daily Demand measure will always show the values for the anchor date setting, which is set to the current planning bucket, and therefore it should not be used for analysis if the anchor date setting is set to the next planning bucket.

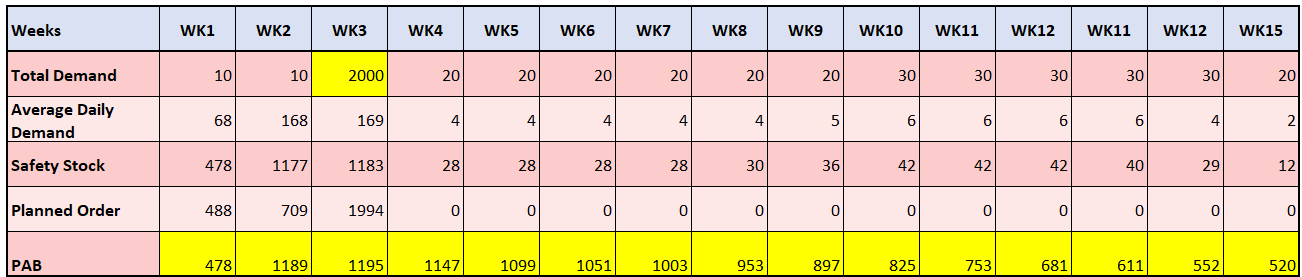

Example 2.1: Average Daily Demand in Weekly Buckets - Default Behavior

In this example, there’s a 5-day work week, Period = 12 days, Days of Cover = 7 days, and Plan Horizon = 15 Weeks.

In this case, the Average Daily Demand is calculated using the current week bucket as the starting point for the Demand Period.

Average Daily Demand Based on the Current Week Bucket

As a result of unusually high demand on Week 3 (WK3), the Shifted Average Daily Demand for Week 3 is calculated to be ((2000/5) × 5 + (20/5) × 5 + ((20/5) × 2))/12 = 169, and the safety stock is therefore 7 × 169 = 1183, which results in a large planned order on Week 3. This causes PAB to remain high to the end of the planning horizon.

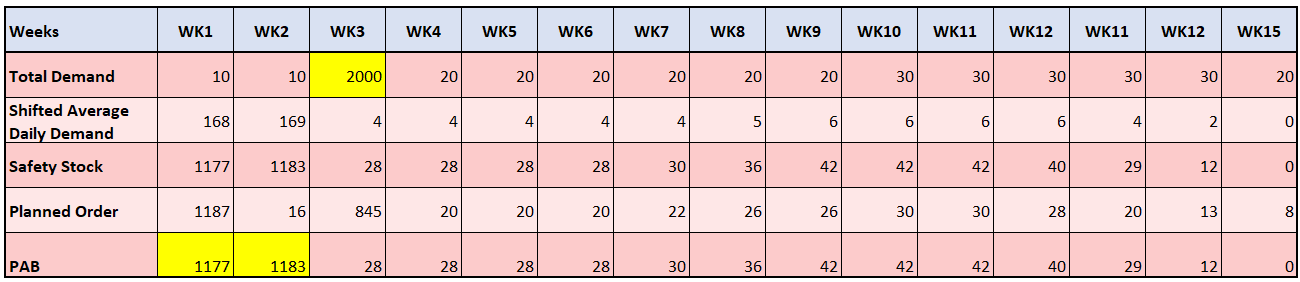

Example 2.2: Shifted Average Daily Demand in Weekly Buckets - Optional New Behavior

In this example, there’s also a 5-day work week, Period = 12 days, Days of Cover = 7 days, and Plan Horizon = 15 Weeks.

But with the new behavior, the Shifted Average Daily Demand is calculated using the next-week bucket as the starting point for the Demand Period.

Shifted Average Daily Demand That Starts Based on the Next Week Bucket

Even with the unusually high demand on Week 3 (WK3), the Average Daily Demand for Week 3 is calculated to be ((20/5) ) × 5 + (20/5) × 5 + ((20/5) × 2))/12 = 4, and the safety stock is therefore 7 × 4 = 28, which results in a smaller planned order on Week 3 compared to the scenario where the Average Daily Demand was calculated based on the current bucket as the starting bucket for the Demand Period. The PAB on Week 3 is reduced because of the smaller planned order on Week 3, and it continues to be much smaller than the previous scenario, from Week 4 to the end of the planning horizon.

Steps to Enable

- There’s a new technical parameter that enables users to implement this feature: UseNextBktAnchorDateForDaysOfCoverSS. The same technical parameter is used for both the Redwood user experience and the classic (non-Redwood) user experience, but it’s entered in slightly different locations.

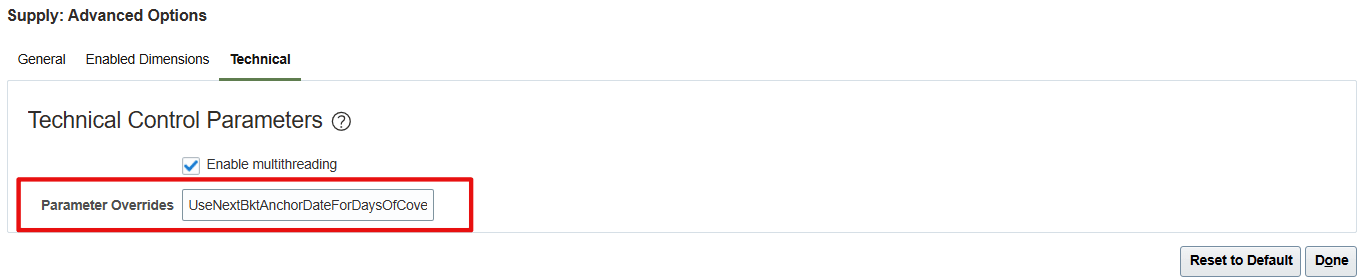

- In the classic user experience, enter UseNextBktAnchorDateForDaysOfCoverSS=true in the Parameter Overrides field on the Technical tab of Supply: Advanced Options in Plan Options.

Parameter Overrides Field in Classic User Experience

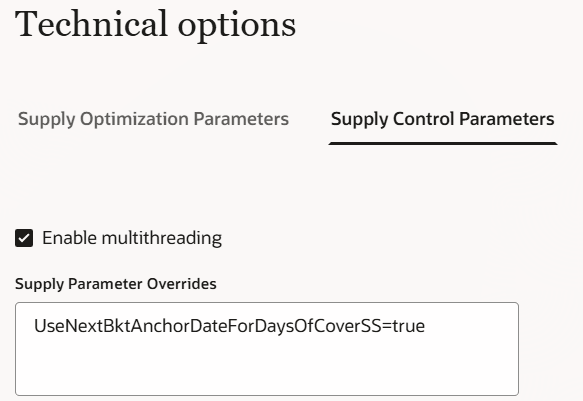

- In the Redwood user experience, enter UseNextBktAnchorDateForDaysOfCoverSS=true in the Supply Parameter Overrides field on the Supply Control Parameters tab of Technical options in Plan Options.

Supply Parameter Overrides Field in Redwood User Experience

Tips And Considerations

- This feature is available for both constrained planning and unconstrained planning.

- The Shifted Average Daily Demand is not a new measure, and it will not be displayed in the UI.

- Unconstrained planning considers the prorated amount of the past due forecast demand that falls into the first planning bucket for calculating safety stock.

- Constrained planning includes the entire past due demand without proration in the first bucket when calculating safety stock.

Key Resources

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supply Chain Planner (ORA_MSC_SUPPLY_CHAIN_PLANNER_JOB)

- Materials Planner (ORA_MSC_MATERIALS_PLANNER_JOB)

These privileges were available prior to this update.