Issue Materials and Complete Products in a Work Order Operation Using a License Plate Number

License plate numbers (LPNs) are commonly used for efficient tracking of a container or pallet of items rather than individual items, lots, or serials. In the context of manufacturing operations, LPNs facilitate material movements between storage and production locations through a single LPN scan.

Now with Advanced Inventory, you can issue, return, and backflush materials directly from an LPN for an operation in a discrete or process manufacturing work order or flow schedule. You can also complete or reverse a product or output quantity for a work order operation and pack it into an LPN. The supply and completion subinventories can be configured to determine whether LPN tracking is required during material, operation, and output transactions.

You can scan or enter an LPN using any of the following Redwood user experiences:

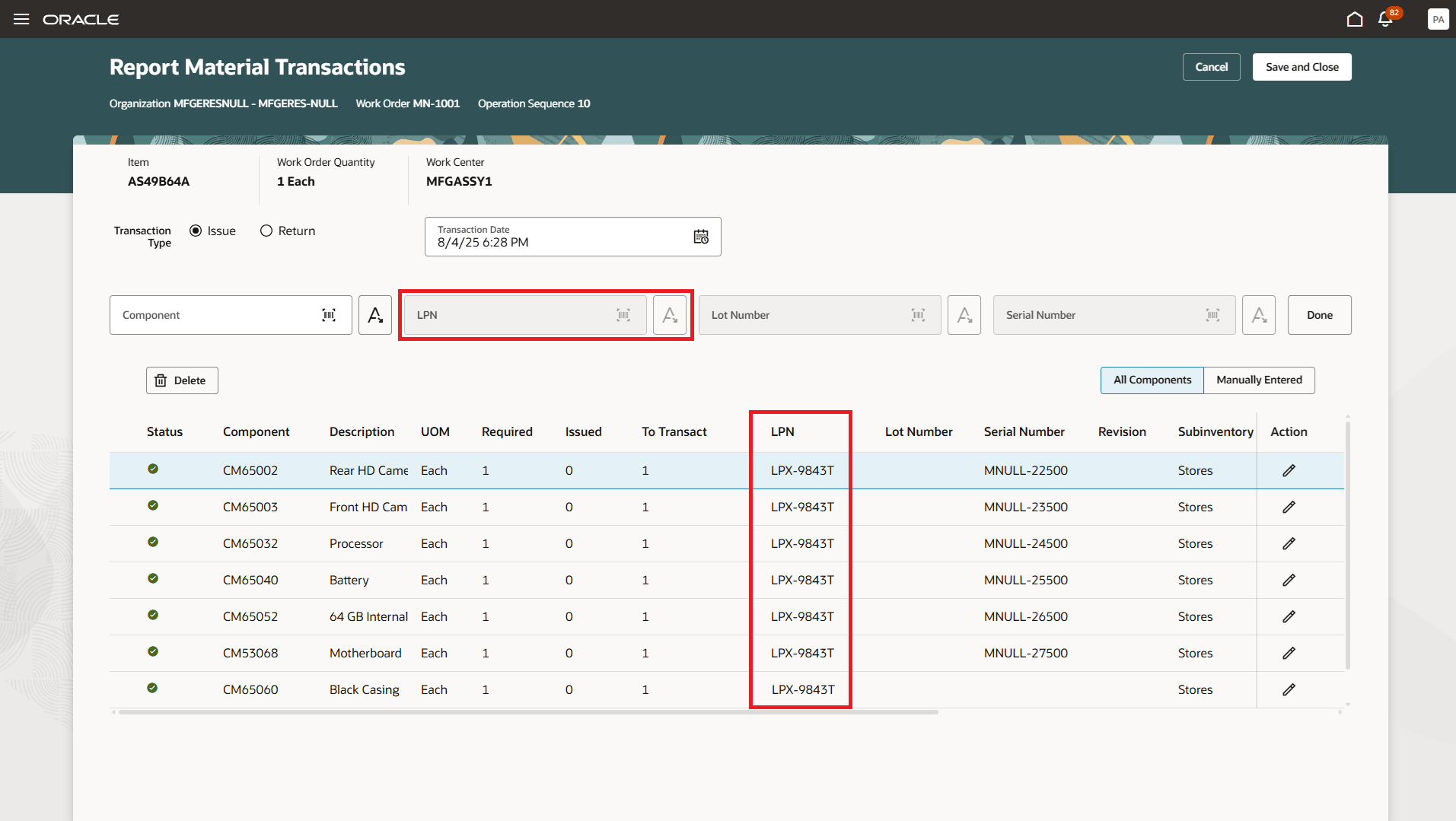

- Report Material Transactions

- Report Orderless Transactions

- Report Flow Schedule Completion

- Production Execution

- Report Operation Outputs using Industrial Handheld Devices

- Issue and Return Materials using Industrial Handheld Devices

- Report Operation Completions, Rejections, and Scrap using Industrial Handheld Devices

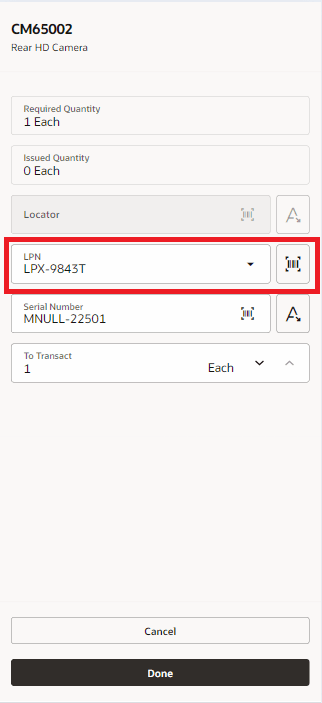

Scan or Select LPNs While Reporting Work Order Material Transactions

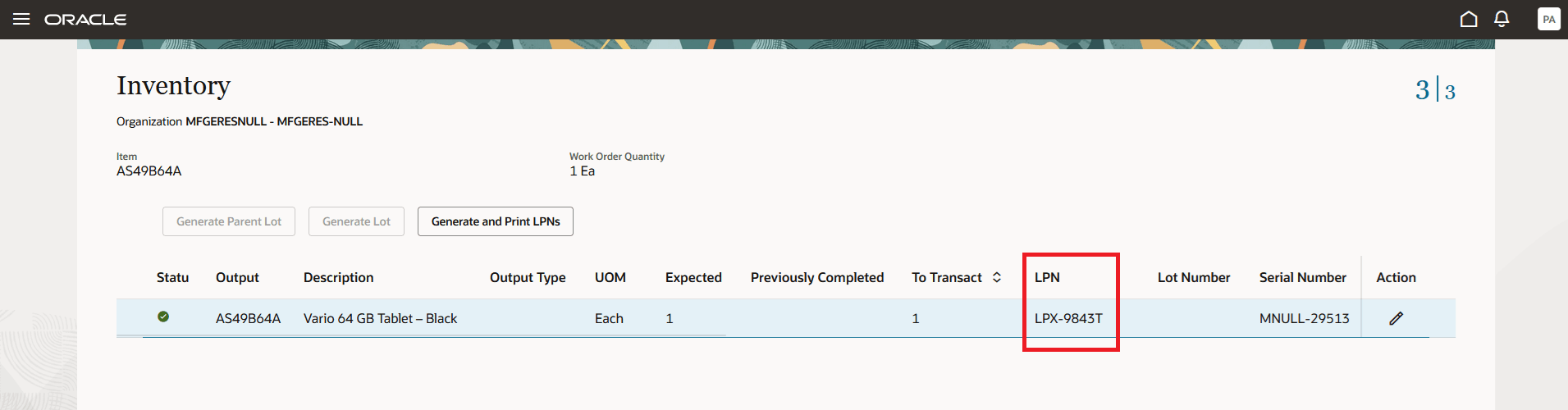

Scan or Select an LPN for the Product While Reporting an Orderless Completion Transaction

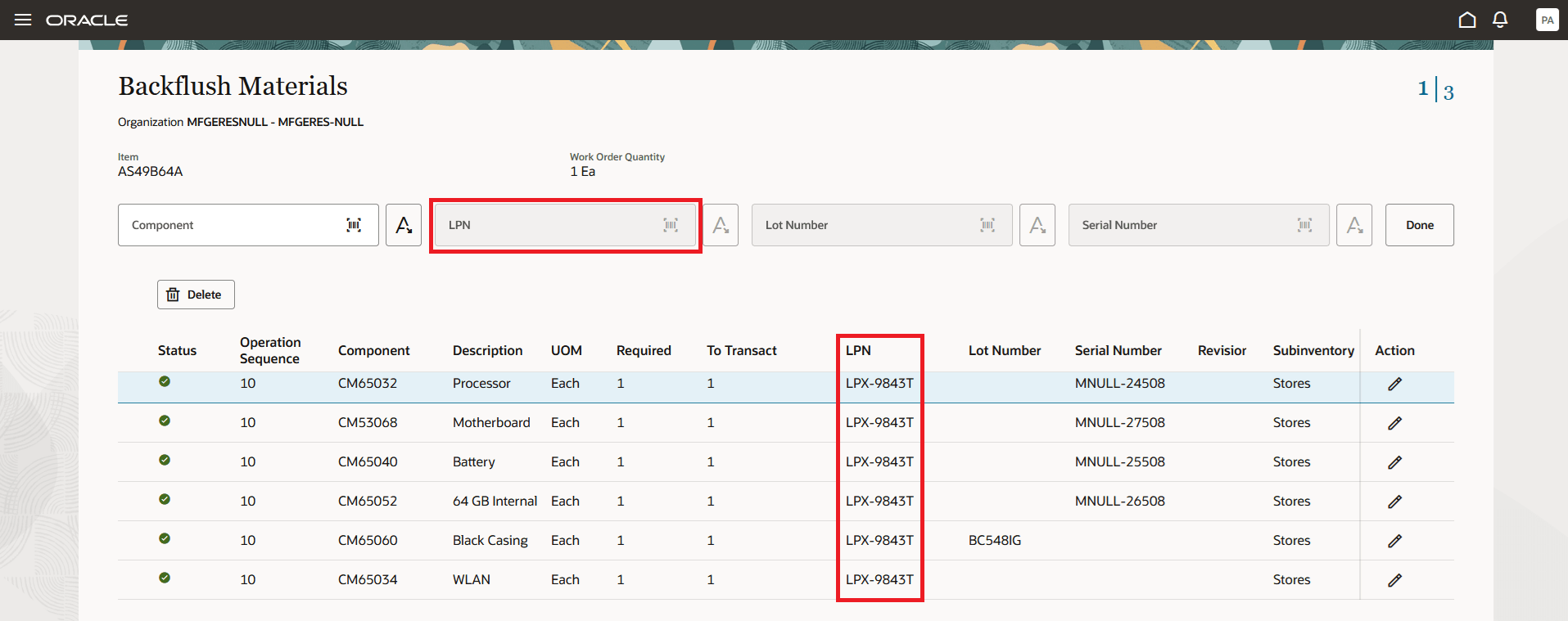

Scan or Select LPNs for Materials While Reporting an Orderless Completion Transaction

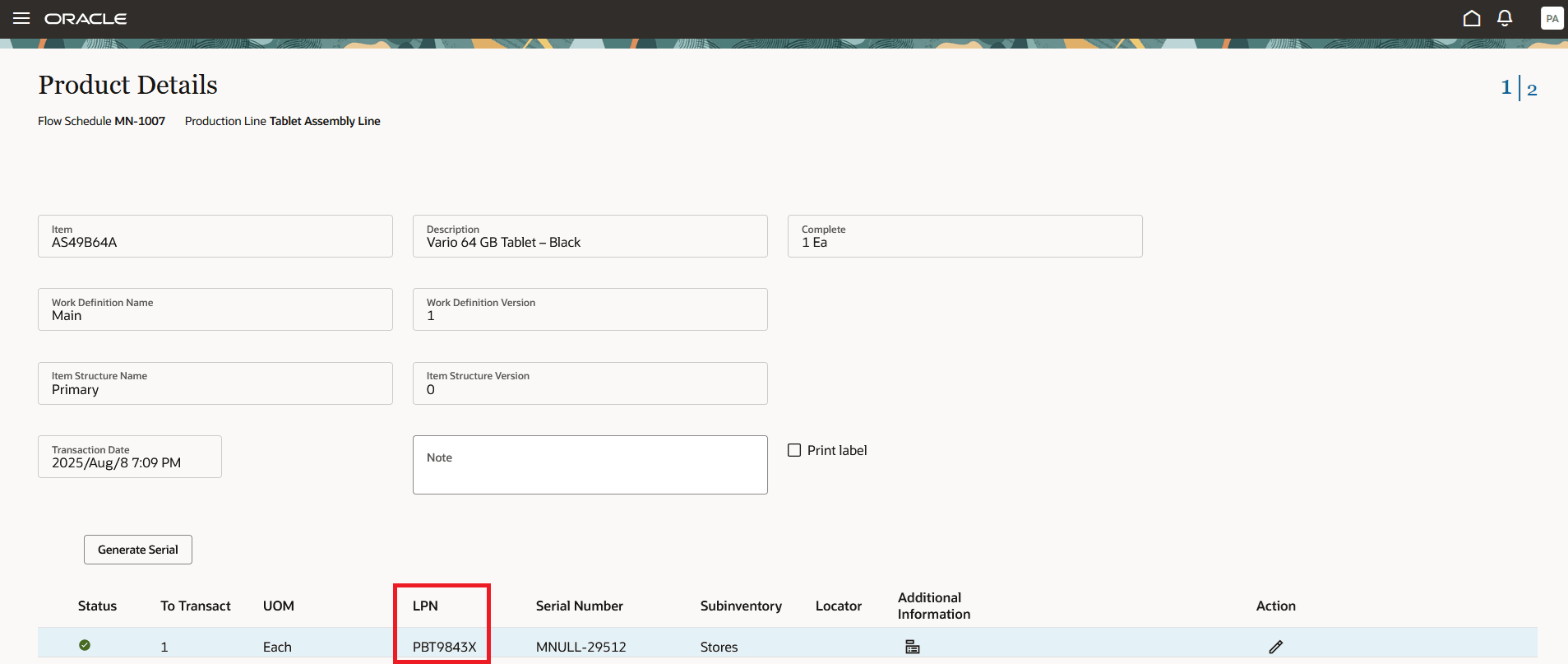

Scan or Select an LPN for the Product While Reporting Completion of a Flow Schedule

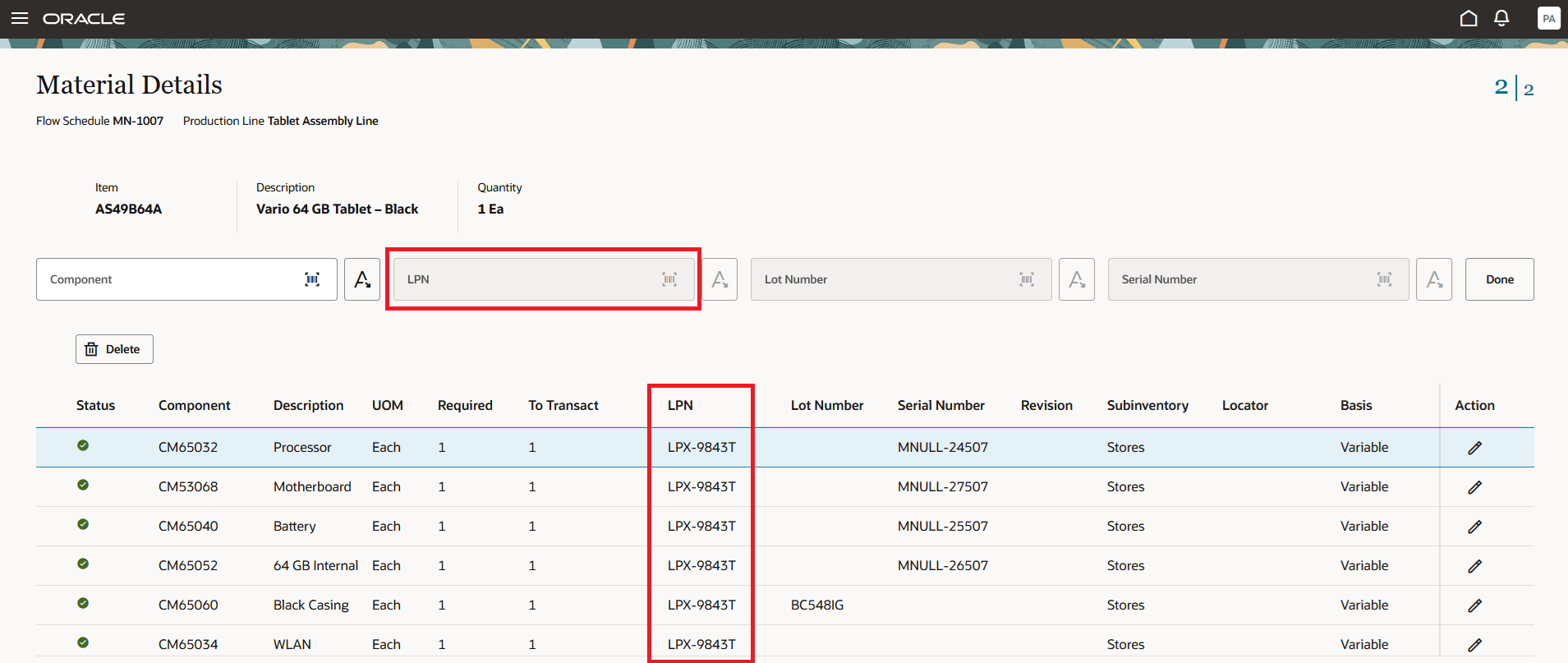

Scan or Select LPNs for Materials While Reporting Completion of a Flow Schedule

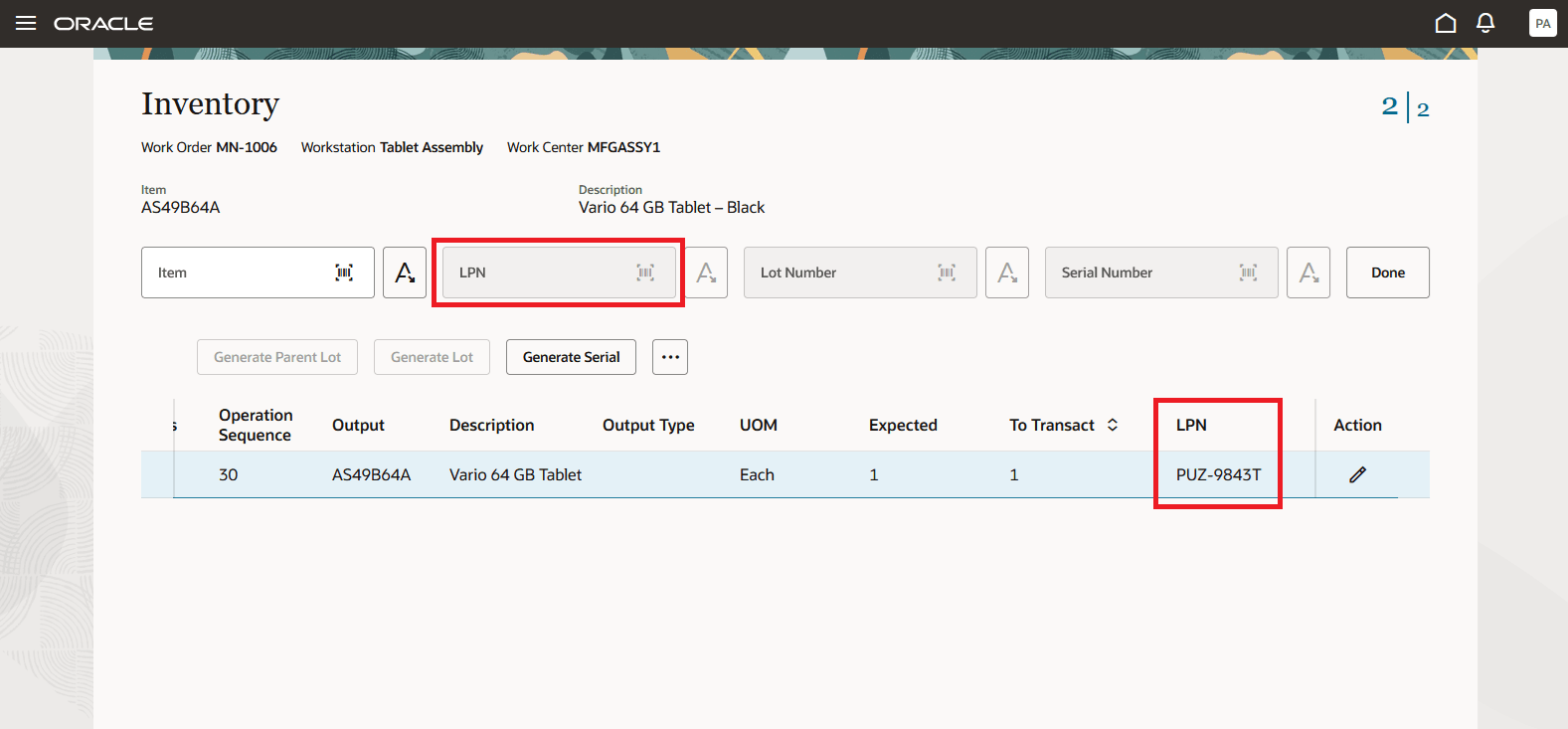

Scan or Select an LPN for the Product While Reporting Operation Completion at a Workstation

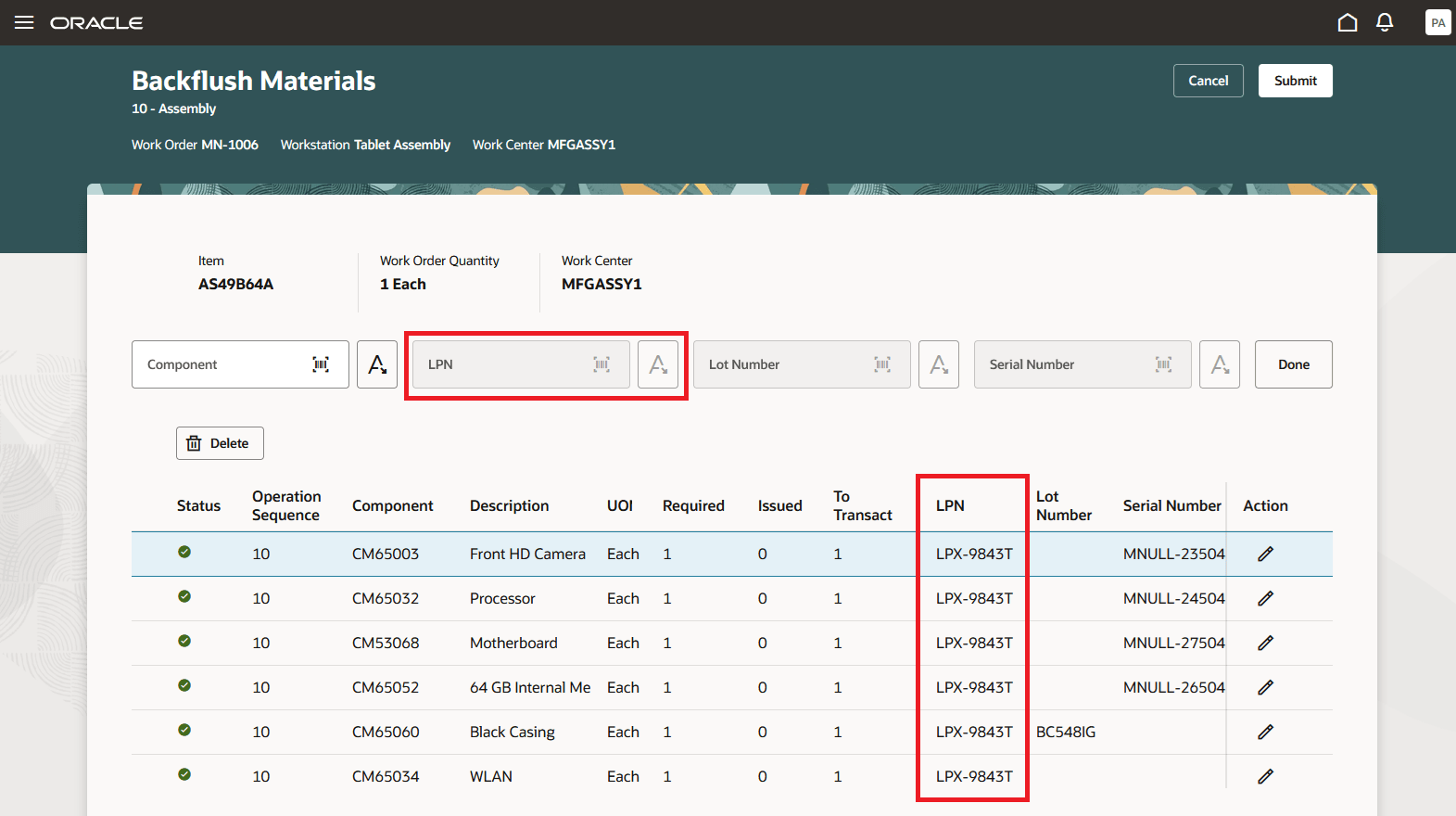

Scan or Select LPNs for Materials While Reporting Operation Completion at a Workstation

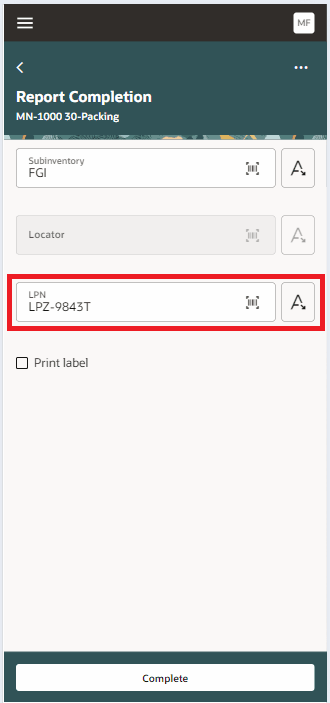

Scan or Select an LPN While Performing an Operation Completion Transaction Using a Mobile Handheld Device

Scan or Select an LPN While Reporting a Material Transaction Using a Mobile Handheld Device

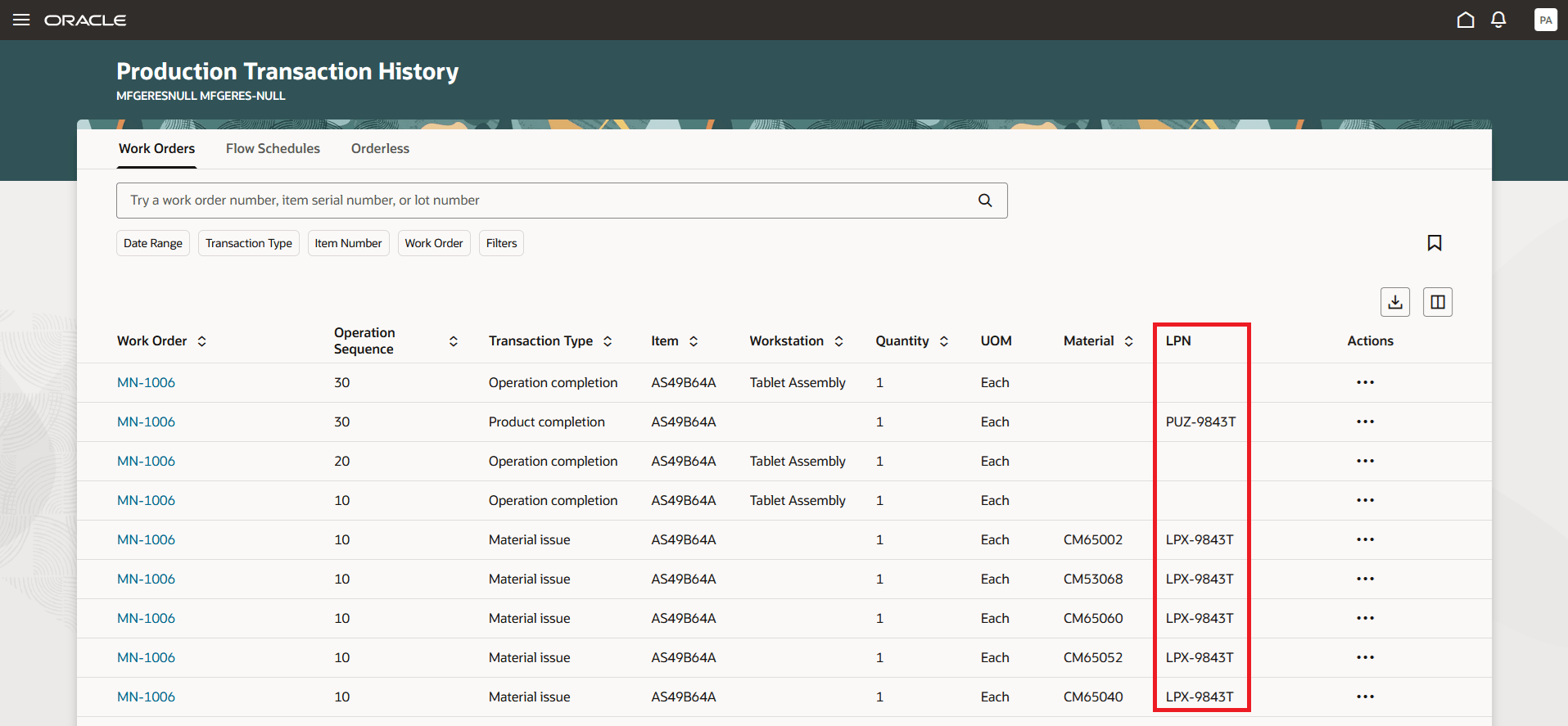

You can review LPNs used in product and material transactions from the Redwood Production Transaction History page.

Review LPNs in Production Transaction History

Embedding LPN support in production transactions minimizes repetitive scans and increases operational efficiency while maintaining product traceability for compliance and audit processes.

Here's the demo of these capabilities:

Steps to Enable

Refer to the Redwood: Use License Plate Numbers to Perform Inventory Transactions feature for more information about the setups needed for using LPNs.

Tips And Considerations

- For Level 2 warehouses and production plants, LPN support in manufacturing transactions requires Oracle Advanced Inventory. For high volume processing in Level 3 warehouses and distribution centers, refer to Oracle Fusion Cloud Warehouse Management System.

- You can't mix loose and packed items in an LPN-controlled subinventory at this time.

- Refer to the following 25D features for more information about mobile manufacturing transactions:

- Issue and Return Materials Efficiently Using Industrial Handheld Devices

- Report Operation Completions, Rejections, and Scrap Efficiently Using Industrial Handheld Devices

- Report Operation Outputs Efficiently Using Industrial Handheld Devices

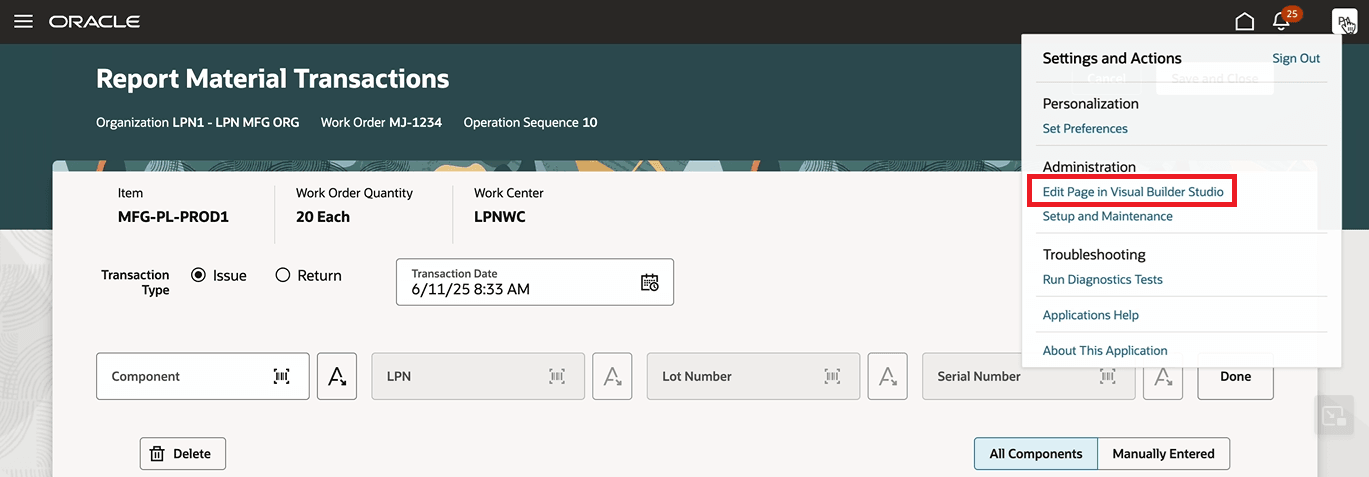

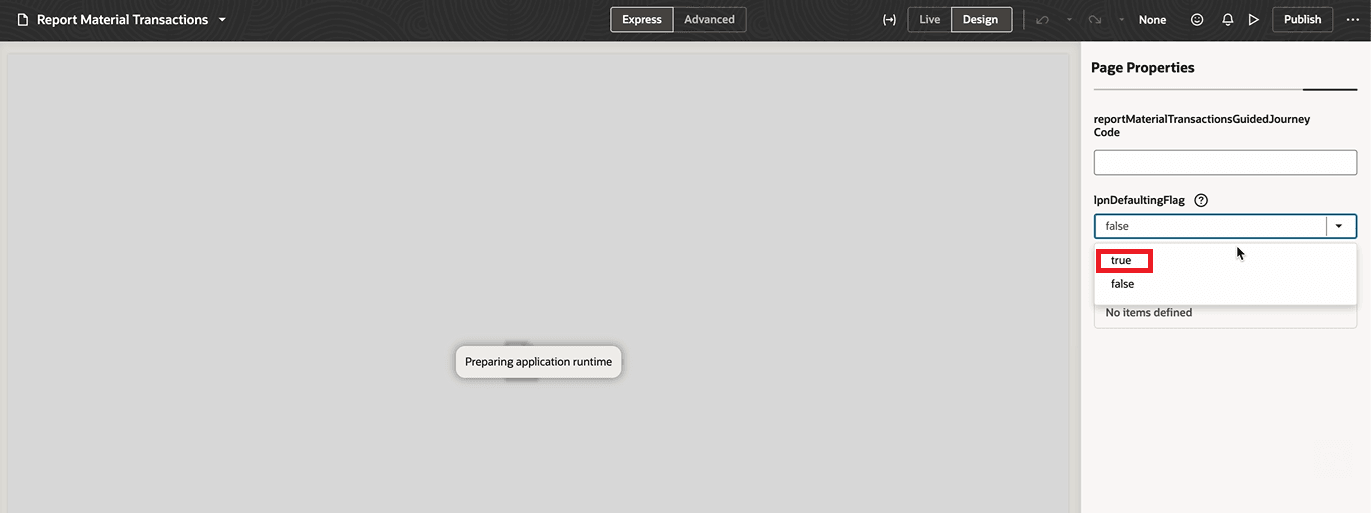

- To default the same LPN across multiple records in the Report Material Transactions and Backflush Materials pages, enable the business rule using the following steps:

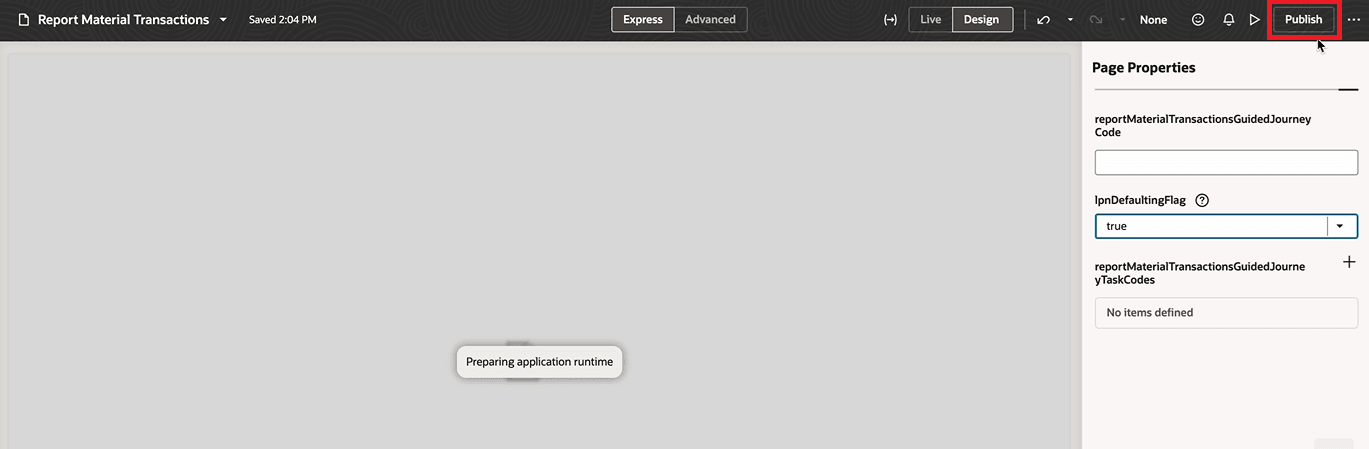

- Step 1: Select Edit Page in Visual Builder Studio from the Settings and Actions menu for the page.

- Step 2: Set the lpnDefaultingFlag attribute to true.

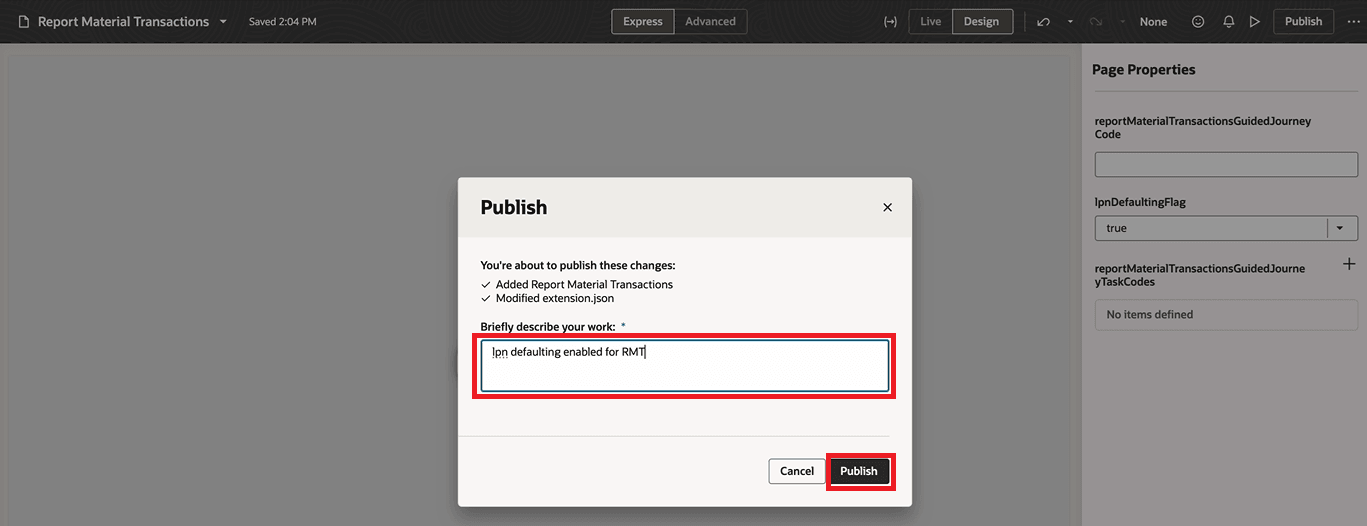

- Step3: Click Publish.

- Step 4: Enter a description for your work and click Publish.

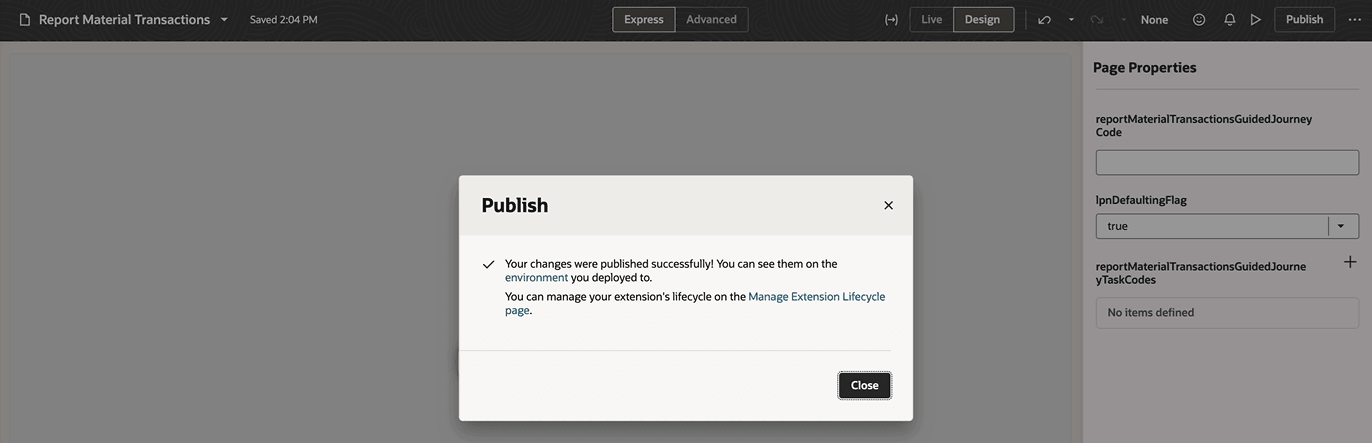

- A confirmation message appears.

Key Resources

- Watch the Issue Materials and Complete Products in a Work Order Operation Using a License Plate Number demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains this duty role can access this feature:

- Advanced Inventory Transaction Duty (ORA_INV_ADVANCED_INVENTORY_MAINTENANCE_DUTY)

This duty role is available from 25C.

NOTE: The Advanced Inventory Transaction Duty duty role is not assigned to any predefined job roles. In the Security Console, you must manually assign the duty role to a configured job role.