Reschedule Sales Orders for Flow Manufacturing Items

Prioritize and reschedule sales orders with items manufactured on production lines. Scheduled dates are based on a steady output rate and available production slots. This makes shipment and delivery estimates more reliable for customers ordering flow-manufactured items. The system also provides supply recommendations and uses available capacity for both flow and discrete manufacturing processes.

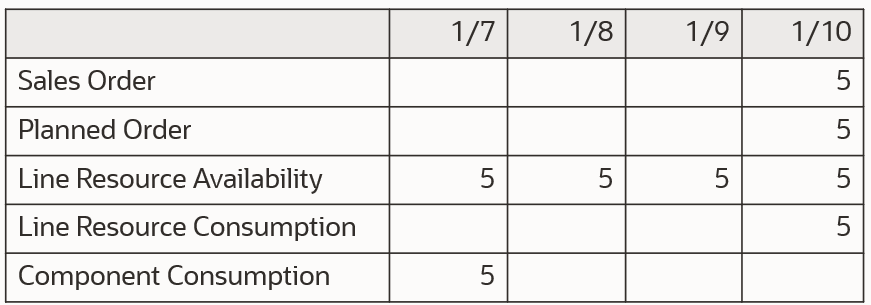

Example 1: Reschedule a sales order line by generating a new planned order and consuming component and flow line capacity

The following key points apply to the data shown in this example:

- System Date (Plan run date): 1/7/2030

- Number of Steps in flow line: 7

- Line Rate: 1 unit/hour

- Takt Time: 1 hour/unit

- Flow line is working daily Monday through Friday for 7 hours

- Daily Line Capacity: 7 units

- Request Type: Ship

- On Hand is available for each component either on the plan start date or by 1/7/2030, and there are no supply constraints

- Sales Order Requested Date: 1/10

- Sales Order Requested Quantity: 5

- Post-Processing Lead and Pick-Pack Lead Time are not set

- The date January 7, 2030, falls on a Monday

Sales Order Rescheduled for a Flow Manufactured Item

Key considerations when rescheduling a sales order line for a flow manufactured item:

- The flow line operates at a strict Takt Time cadence. One unit is completed at the end of the flow line during each Takt Time interval while the line is working. Each unit spends a total of (Number of Stations × Takt Time) working hours on the flow line.

- Even if a unit requires no processing at a specific station, it still occupies the line for the full duration. Units cannot skip ahead in the sequence, as production order is determined by the flow schedule build sequence. Therefore, each unit spends: (Number of Stations × Takt Time) working hours on the flow line.

- The line rate, or the number of production slots available per day, is calculated as: (Working hours per day ÷ Takt Time).

- Flow manufacturing is capacity-constrained in terms of units, not time. As a result, each unit occupies: (Number of Stations) production slots on the flow line.

- To ensure availability of components for all units scheduled for production on January 10, 2030, components must be available by January 7, 2030.

This is because Backlog Management plans at the day level and does not define the exact production sequence within the day. Therefore, all components must be available before the first unit enters production on that day.

Flow Line Component Requirement Date Offset on Jan 7th

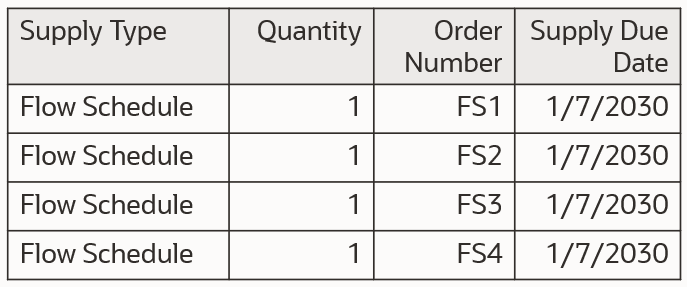

Example 2: Reschedule the sales order line for a back-to-back order reserved for flow schedules

The following key points apply to the data shown in this example:

- System Date (Plan run date): 1/7/2030

- Number of Steps in Flow line: 3

- Line Rate: 0.5 unit/hour

- Takt Time: 2 hour/unit

- Flow line is working daily Monday through Friday for 8 hours

- Daily Line Capacity: Daily working hours * Line Rate for 4 Units

- Request Type: Ship

- On Hand is available for all components either on the plan start date or by 1/7/2030, and there are no supply constraints

- Sales order line for back-to-back item is reserved for flow schedules

- Post-Processing Lead and Pick-Pack Lead Time are not set

- The date January 7, 2030, falls on a Monday

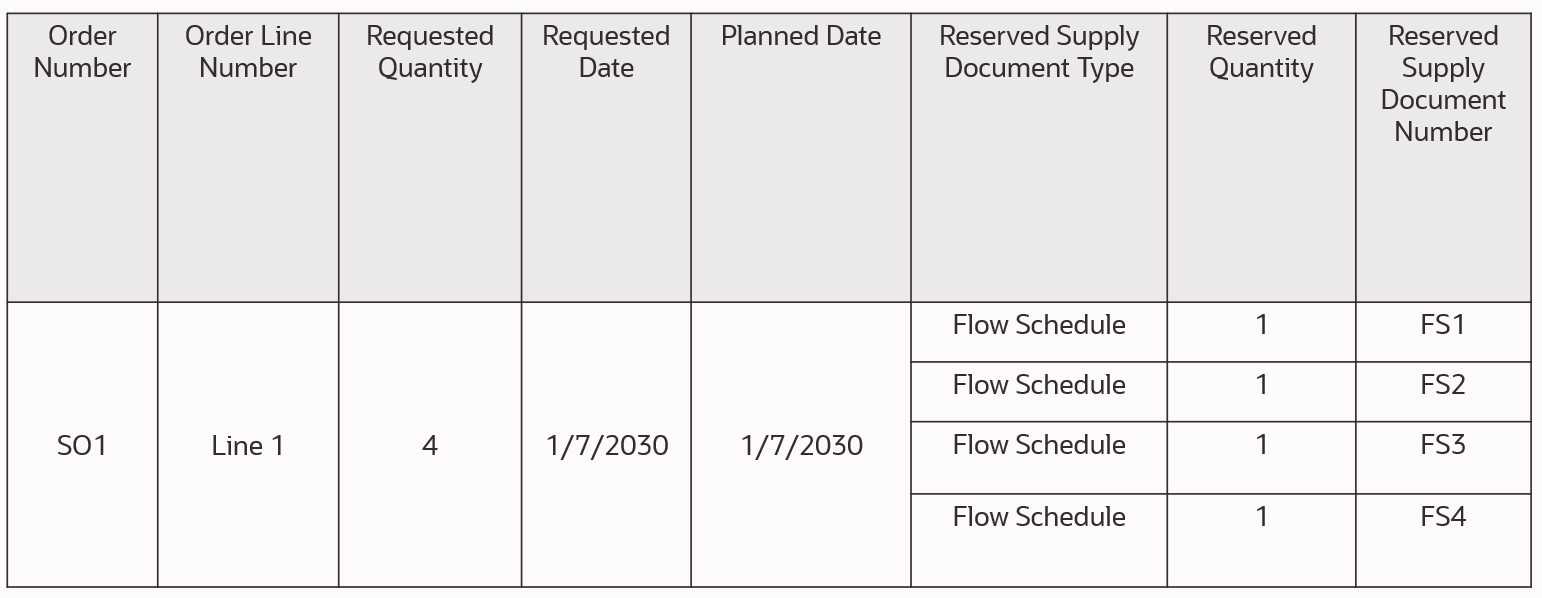

From the collected data, there are four flow schedules, each for one unit, as shown in the Supplies and Demands table in the Plan Inputs work area.

Flow Schedules for Back-to-Back Item Collected in Plan Inputs

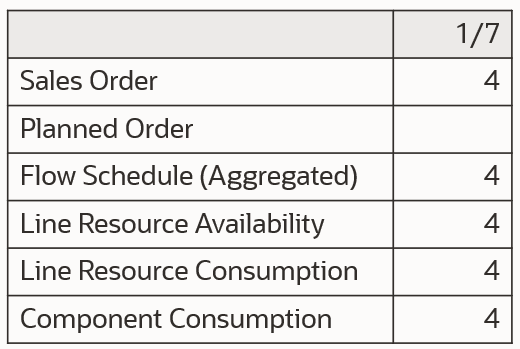

The sales order for back-to-back item is rescheduled to January 7th, 2030, using the flow schedule supply reserved for this order.

Flow Line Capacity and Component Consumption for Flow Schedules

Sales Order Reserved for Flow Schedules Planned in Backlog Management

Example 3: Reschedule sales order line for back-to-back order reserved for flow schedules displayed on the Backlog Analysis page

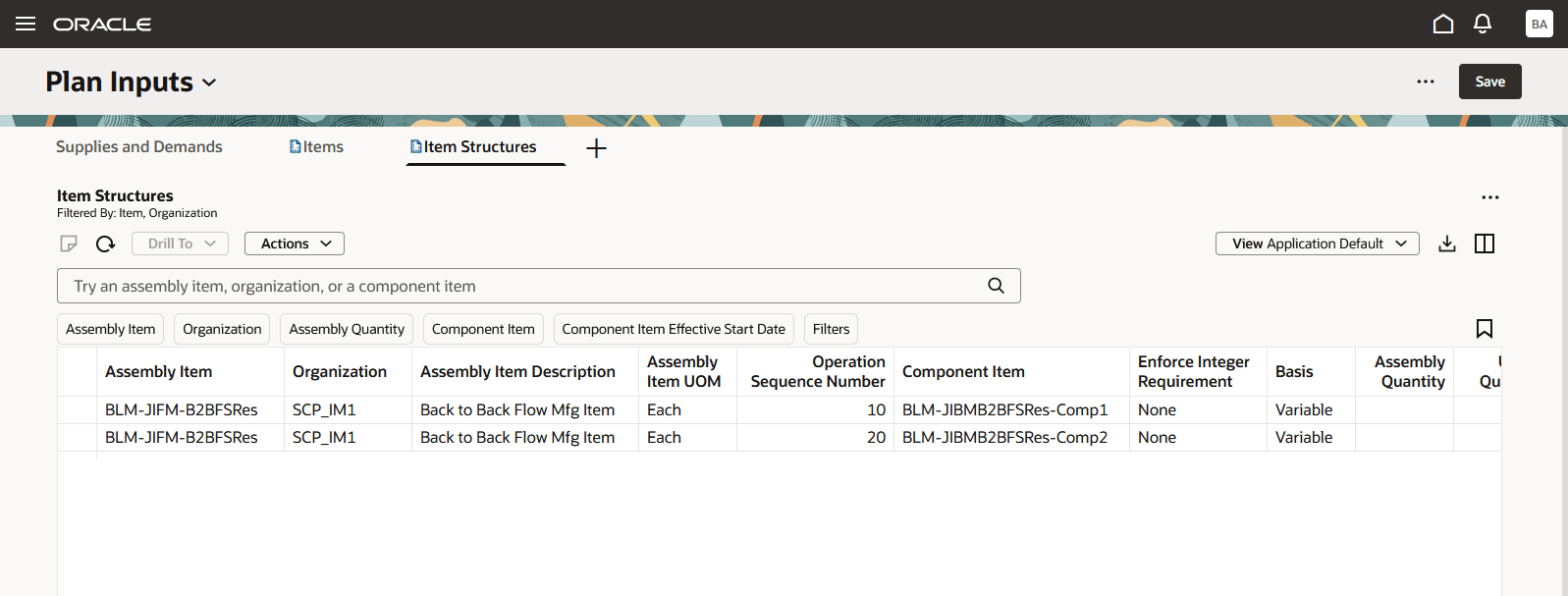

You can view the flow manufacturing items and their component details on the Item Structures page.

Item Structure for the Flow Manufactured Back-to-Back Item

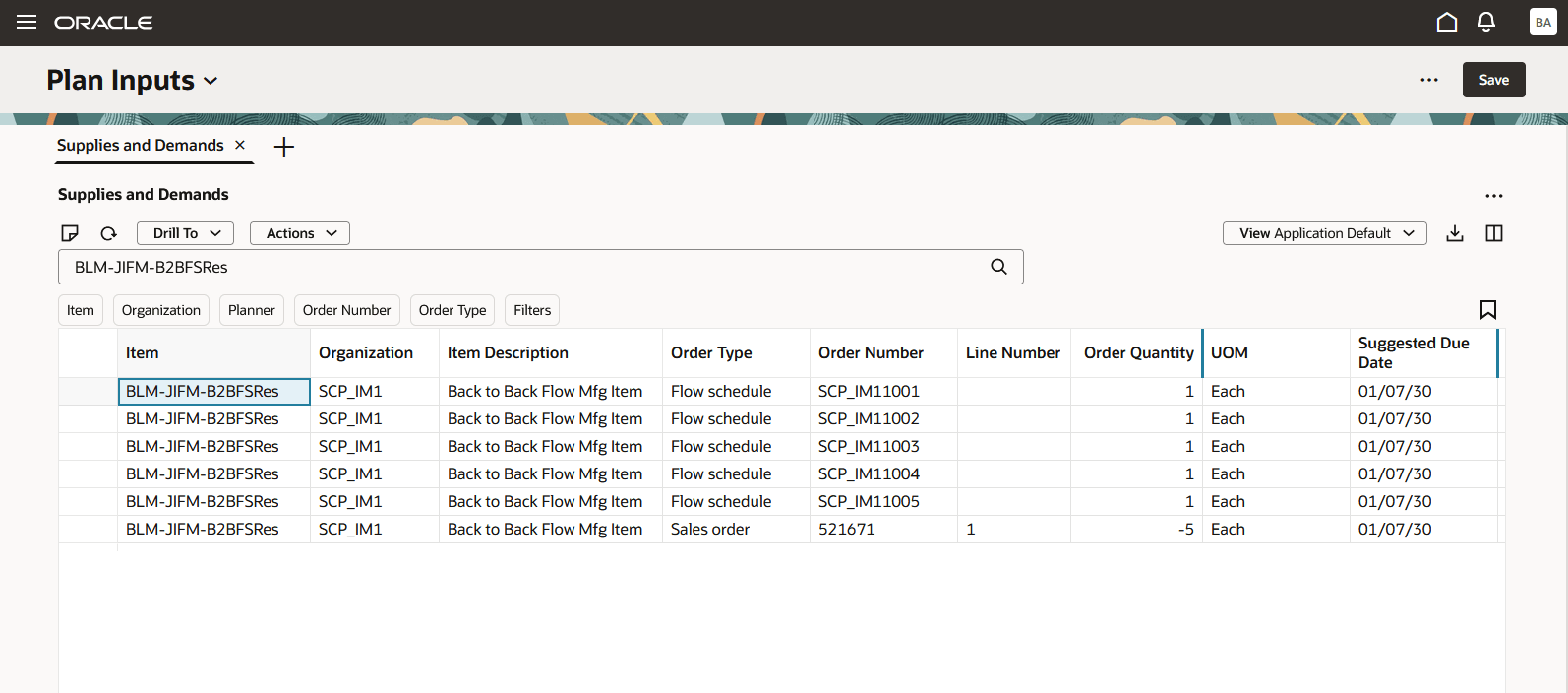

You can view sales orders and flow schedules for flow manufactured items in the Supplies and Demands table in the Plan Inputs work area.

Supplies and Demands UI Under Redwood Plan Inputs

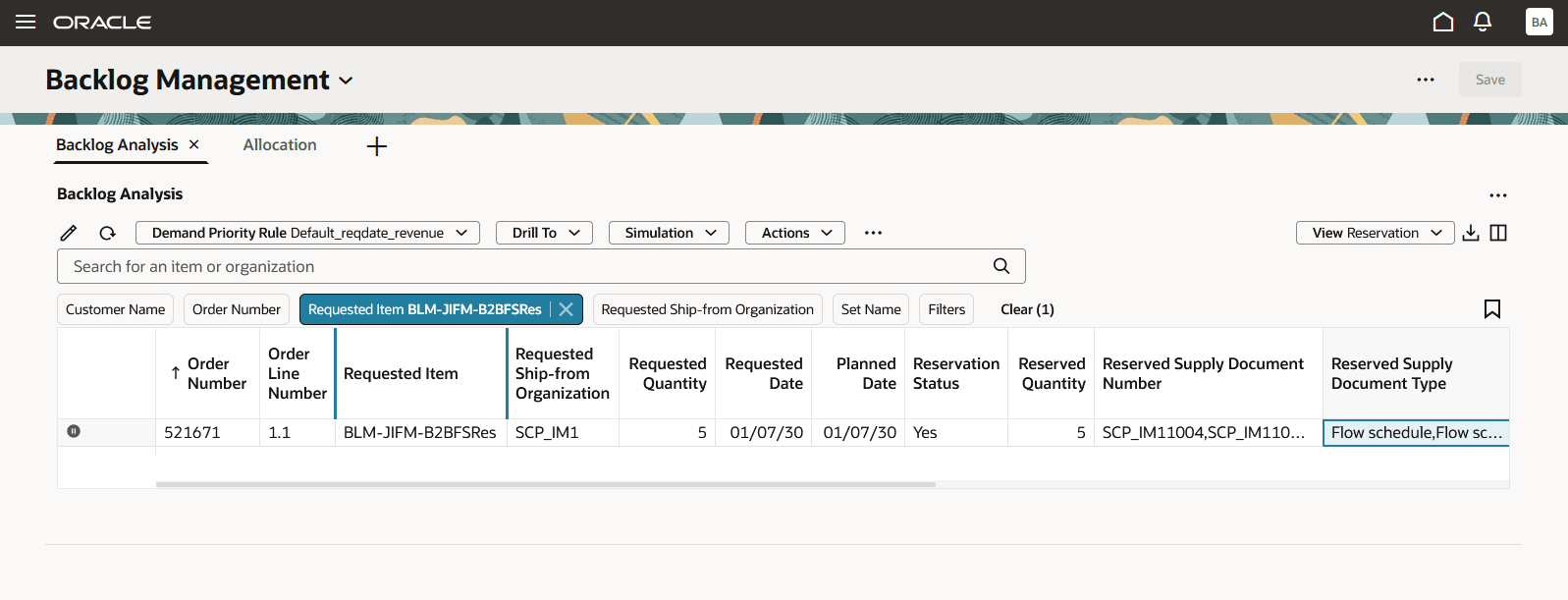

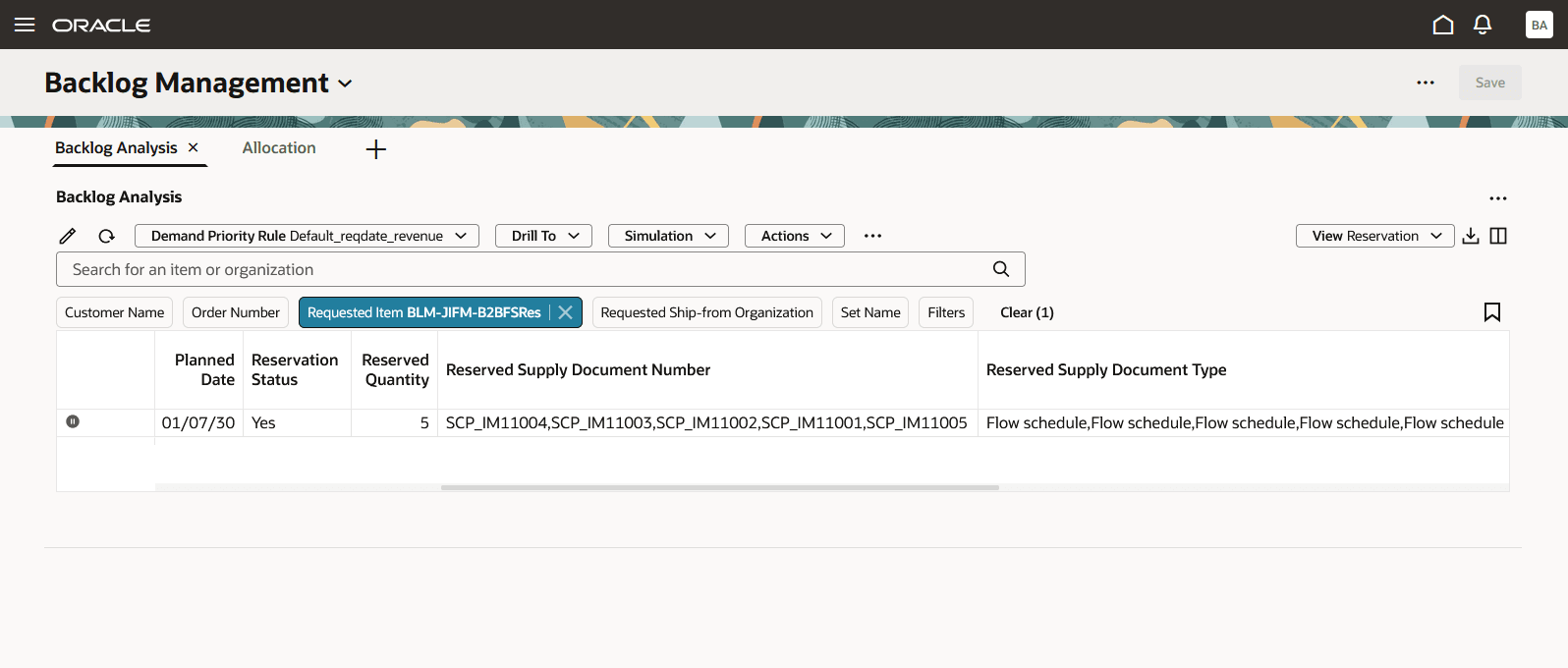

You can view sales orders that are planned by consuming reserved flow schedules supply on the Backlog Analysis page.

Sales Order Line is Reserved for Flow Schedules

You can expand the width of the Reserved Supply Document Number column to view the full list of flow schedules order numbers reserved for the sales order.

5 Flow Schedules Order Numbers are Shown in Reserved Supply Document Number Field

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

Tips And Considerations

If you want to use the Reschedule Sales Orders for Flow Manufacturing Items feature, then you must opt in to its parent feature: Order Backlog Management. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

Additional tips and considerations:

- Back-to-back flow schedules are automatically created with a quantity of 1 per schedule.

- Shrinkage is not applied in flow manufacturing. The planning process ignores shrinkage factors, even if they are configured.

- Manual reservations for flow schedules are not supported in back-to-back scenarios.

- Mixed-mode manufacturing is supported. A subassembly can be manufactured using flow, while the finished assembly uses discrete manufacturing—and vice versa.

- Flow manufacturing requires the Redwood UI. For example, to view flow schedules reserved for a sales order line, use the Redwood Backlog Analysis UI for the best experience.

- Flow schedule supply is considered only if the Standard Work Order attribute is enabled in the Backlog Planning Rules UI. A future Redwood UI for Manage Backlog Planning Rules will introduce an explicit attribute for including flow schedule supply.

- If a flow schedule has partially completed operations, Backlog Management will only consume components and flow line capacity for the remaining operations. For example, a flow schedule consists of three steps, with Component A, Component B, and Component C consumed in steps 1, 2, and 3 respectively. If the flow schedule is in an intermediate status—having completed Steps 1 and 2—only Step 3 remains. In this case, Backlog Management will consume flow line capacity and Component C exclusively for Step 3 to complete the schedule.

Key Resources

- Refer to the Cloud Applications Readiness content for the following 25C Supply Planning feature for more information:

- Plan Production Targets for a Flow Manufacturing Production Line

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Monitor Backlog Management Work Area (MSC_MONITOR_BACKLOG_MANAGEMENT_WORK_AREA_PRIV)

- Create Backlog Plan (MSC_CREATE_BACKLOG_PLAN_PRIV)

These privileges were available prior to this update. The following site-level profile should be enabled:

- Redwood Backlog Management Pages Enabled (ORA_MSC_BACKLOG_MANAGEMENT_REDWOOD_ENABLED)