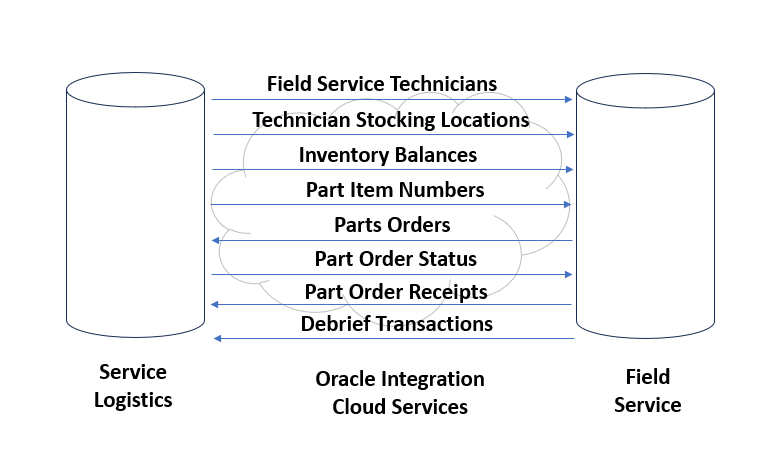

Integration Component Architecture Between Service Logistics and Field Service

Information flows between Service Logistics and Field Service using integrations.

Overview

Service Logistics lets customers optimize parts logistics, source and order service parts, record costs, invoice customers, and update inventory and the installed base. Field Service offers time-based, self-learning, and predictive technology for dispatching field service technicians to resolve customer issues.

Oracle Integration (OIC) offers a rich set of business and technical integrations called accelerators, and also sample templates called recipes. See the Requirements and Licensing topic to learn about the required subscriptions details.

This diagram shows how information flows between Service Logistics and Field Service using the integrations in the Oracle Service Logistics — Oracle Field Service | Integrate Supply-Chain Data recipe package:

The following summarizes the Service Logistics to Field Service integrations:

Field Service Technicians Download: Field service technicians are set up as person parties in Oracle Fusion Trading Community model. A field service technician usage can be associated with a person party from several Oracle Cloud user interfaces (UIs), including the Service Logistics Manage Field Service Technicians setup UI. An integration cloud service then creates the technician in Field Service if the technician doesn't exist, or updates the technician if they already exist.

Stocking Locations and Inventory Balances Download: Subinventories defined in Oracle Fusion Inventory Management can be set up as stocking locations in the Service Logistics Manage Stocking Locations setup UI. Once defined as stocking locations, these subinventories are assigned a technician type. Stocking locations can then be assigned to technicians in the Service Logistics Manage Field Service Technicians setup UI. Stocking locations hold parts inventory that technicians use when fixing customer issues. An integration cloud service then periodically syncs stocking locations and their inventory balances from Inventory Management to Field Service.

Stocking Locations and Inventory Balances Incremental Download: Instead of loading all inventory balances, which takes a long time to complete, only items transacted on the same day as the integration are loaded. This is a smaller subset of all items and runs much faster. You should set up this integration to run multiple times a day and every day of the week.

Technician Inventory Balances Download: An alternative to the stocking locations and inventory balances download, this integration stores the inventory balances directly on the technician resource instead of the truck resource. This is a more common approach among Oracle Field Service Cloud (OFSC) customers. Only inventory balances in the technician's default usable stocking location, as defined in Service Logistics, are synced. This integration should only be used if the technician is assigned to only one stocking location.

Technician Inventory Balances Incremental Download: Instead of loading all inventory balances, which can take a long time to complete, the only items loaded are those that have been transacted on the same day that you run the integration. This is a smaller subset of all items and runs much faster. You should set up the integration to run multiple times a day and every day of the week. This integration should be used if the technician is assigned to only one stocking location.

Part Item Number Download: The Supply Chain Cloud parts catalog is downloaded to OFSC, so that field service technicians know which parts they can order. Only items with a material service billing type and an inventory organization that matches the user’s Default Inventory Organization profile option (INV_DEFAULT_ORG_ID) are downloaded to OFSC.

Parts Order and Receiving: A field service agent can start a part order directly from Oracle Field Service Cloud (OFSC). This action generates a part requirement line within the associated work order. Based on the categorization of the part, the system either creates a transfer order (for inventory-managed parts) or a purchase requirement (for buy-only parts).

The parts processing integration between Oracle Service Logistics and OFSC is achieved through four key integrations, all are available as part of the Oracle Field Service | Integrate Supply-Chain Data recipe package in the Oracle Integration Cloud (OIC) Marketplace.

Preventive Maintenance Work Orders: In addition to the ESS job that generates Preventive Maintenance service requests and work orders, there's a recipe that does the same thing. However, the OIC recipe is highly configurable, while the ESS job isn't.

See the Set Up Field Service Preventive Maintenance topic in the Getting Started with Service Logistics Implementation Guide for details on how this OIC recipe gets the work order area from OFSC using the Fusion Service API, which is needed to create the Preventive Maintenance work order.

Field Service Debrief Integration: Field service activities are created when a service work order is created in the Oracle Fusion Service UIs. Field service technicians use the OFSC debrief UI on their mobile devices to report:

- Labor hours recorded.

- Parts used and recovered.

- Expenses incurred on the activities assigned to them.

When the activity is completed, these debrief transactions are automatically created in Service Logistics and are visible in the Manage Charges and Estimates page. Field Service Administrators can then:

- Review these debrief transactions.

- Make any changes or corrections.

- Post the debrief transaction.

This generates a customer invoice for billing, adjusts inventory balances, updates the customer's asset configuration, and captures the cost of service.

Auto Parts Debrief: Part installation debrief lines are created in OFSC when the field service technician starts an OFSC activity. These debrief lines are created for parts ordered in Fusion Service and Service Logistics UIs, and for those created in OFSC.

Custom Rule Processor: Provides an option to enable a business rule while posting charges. Customers can implement a business specific rule that's configured in this integration, which acts as a post charge processing rules engine.

See the Extend Charges Posting Rules topic in the Getting Started with Service Logistics Implementation guide for details on how you can define custom processing rules to post charges in Service Logistics.

Purchase Order and Transfer Order Processing

This integration is for non-serialized items only. If you create an advanced shipment notification in the Supplier Dashboard, you can't enter serial numbers.

It also only works for purchase orders created for part requirements that are created in OFSC.

Oracle Integration (OIC)

See the Oracle Integration (OIC) Recipe chapter for information about the Oracle Service Logistics — Oracle Field Service | Integrate Supply-Chain Data recipe package.