Guidelines for Creating a Bill of Resources

Use these guidelines to help make sure your bill of resources meet your needs.

Set Up Promising

- You must have an ATP rule for your item. The rule must use the Supply Chain Search mode and you must enable the Search Components and Resources option on the rule.

- If you use transit times, then you must specify them.

- You must have a local, Make At sourcing rule for your item and assign it to an assignment set.

Mark Your Items and Resources as Critical

There are different ways to do this:

- Use the Critical Component attribute in the Items area when you create a simulation set in the Plan Inputs work area. Use it to make assemblies, subassemblies, and items critical in your manufacturing organization.

- Enable the Bottleneck option in the Resources area in the simulation set to make a resource critical. As an alternative, enable the Capable to Promise option when you create the resource in Manufacturing.

- Use the Critical Component attribute when you import through REST API or file-based data import. Specify the name of the simulation set and import the item that you need to mark critical.

- Use REST API when you have to make a large number of items critical. If you only have to update a few records, then you can use the Plan Inputs work area to create a simulation set instead of using REST API.

You can't use the Product Information Management work area to specify that your item is critical.

For details and examples, go to REST API for Oracle Supply Chain Management Cloud, then expand Supply Chain Planning.

Consider When Your Items Are in Effect

Promising will determine when each item is in effect, and promise the item according to the Effective Start Date and Effective End Date. Make sure you set these dates on your work definitions so they work as you expect them to.

Assume Denver is D1, Los Angeles is M1, and the CM153 is a chip on the AS301 motherboard. You have an agreement with your supplier in Taiwan to start using the new CM154 chip by 6/01/2022.

You plan to use the CM153 from 12/01/2021 to 5/31/2022, and the CM154 from 6/01/2022 to 11/30/2022. The schedule process will examine the work definition to get these dates, and Promising will use them to determine availability.| Item in D1 | Manufacturing Component in M1 | Component Type | Lead Time Offset | Usage | Effective Start Date | Effective End Date |

|---|---|---|---|---|---|---|

| AS301 | CM153 | Item | 5 Days | 2 | 12/01/2021 | 5/31/2022 |

| AS301 | CM154 | Item | 6 Days | 2 | 6/01/2022 | 11/30/2022 |

Consider Your Calendars

If you specify lead times for the item in the v work area, such as Processing Days, then the bill of resources will consider transit times and processing times. The bill of resources might need to consider more than one calendar to get an accurate lead time, but all of these calendars might not be available. A bill of resources might skip critical points in the supply chain.

Assume the bill of resources for the AS54888 Laptop Computer at the Denver distribution center includes the Motherboard component from the Los Angeles factory. Los Angeles gets the chips it needs for the motherboard from Taiwan. Each of these locations has its own calendar, and its own shipping, receiving, and transit times. The Lead Time Offset for the Motherboard is 45 days:

- 40 days are for the transit time from Taiwan to Los Angeles.

- 1 day is for the processing time that Los Angeles needs to assemble the motherboard into the laptop.

- 4 days are for the transfer time from Los Angeles to Denver.

Run the Scheduled Process

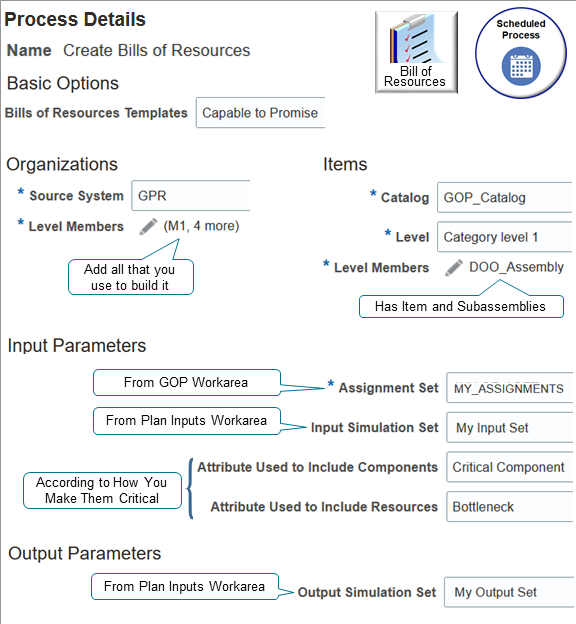

You use the Create Bills of Resources scheduled process.

Set the parameters.

| Parameter | Value |

|---|---|

| Bill of Resources Template |

You typically set this attribute to Capable to Promise. If you're migrating your work definitions, then set it to Unfiltered Capable to Promise. Don't set it to Item Level for Aggregate Planning. That value is for another application. |

| Plan | Leave this parameter empty. |

| Source System | Select the system that contains the organizations that contribute to making the item available in your supply chain. |

| Level Members in the Organizations area |

Select all the organizations that contribute to making the item available. Assume you build the item in your M1 Warehouse and M2 Warehouse, and that these warehouses transfer in a subassembly for the item from your M3 Factory, M4 Factory, and S1 Supplier. You would select:

The value that you set in the Source System parameter determines the members you can select. |

| Catalog | Select the same catalog that you use on your assignment set, such as GOP_Catalog. |

| Level |

Category Level 1 The scheduled process comes predefined to use Category Level 1 for GOP_Catalog. In most situations, you use GOP_Catalog and Category Level 1. For details about catalogs and categories, see How Catalogs Work Together. |

| Level Members in the Items area |

Select the categories of items that you want to use in the bill of resources. For example, if you select DOO_Assembly, then the bill of resources will have items that are in the DOO_Assembly category. Make sure the item and all the subassemblies that you use to build the item are in the category that you select. If they aren't, then you need to add them to the category before you can run the scheduled process. |

| Assignment Set |

Select the assignment set that has the sourcing rules that you use to promise. You use the Global Order Promising work area to create the set. The scheduled process will use these rules as input to the bill of resources that it creates. |

| Input Simulation Set |

Select the simulation set that you created in the Plan Inputs work area specifically for this run of this scheduled process. You can use different input simulation sets to create different bills of resources, examine how each one performs, then select the one that works best for you. |

| Attribute Used to Include Components |

If you set the Bill of Resources Template parameter to:

|

| Attribute Used to Include Resources |

You must make each resource a critical resource, If you make them critical by. . .

|

| Bill of Resources Structure | You must use Within Organization. |

| Planning Product Level | You must use Item. |

| Output Simulation Set |

Select the simulation set that you created in the Plan Inputs work area specifically for this run of this scheduled process. Select a set that's different from the set that you specify in the Input Simulation Set parameter. You can use different output simulation sets to create different bills of resources, examine how each one performs, then select the one that works best for you. |

Note

- You must collect your work definitions, item structures, resources, and transit times before you run the Create Bills of Resources scheduled process. If you update any of this data, such as adding a new organization, then you must collect data again. For details, see Collect Data for Global Order Promising.

- The scheduled process only looks at primary work definitions.

- You must set up your sourcing rules, ATP rules, and assignment set before you run the scheduled process.

- You must create your simulation sets before you run the scheduled process.

- Sign in with the privileges that you need to run scheduled processes. You can't run the process without them.

- A bill of resources treats a phantom item in the same way that it treats an item that isn't a phantom.

Set the Frequency on the scheduled process so it runs whenever the data that the process looks at changes. You must run it every time you add or change:

- The Item or the item's manufacturing components in the Product Information Management work area

- Work definitions for the items or resources in the Work Definition work area

- Critical markings on the items, manufacturing components, or resources

- Sourcing rules, ATP rules, or assignment sets in the Global Order Promising work area