Create Sourcing Rules for Your Configuration Model

Create a sourcing rule to specify where and under what circumstances to make your model and its components available to your customer.

Assume you need a sourcing rule that sources the Build My Laptop model from Seattle Manufacturing. Seattle Manufacturing stocks the required components and the configure options. Their job is to assemble the components according to the choices that your user makes on the sales order.

Try it.

-

Go to the Global Order Promising work area, then click Tasks > Manage Sourcing Rules.

-

On the Manage Sourcing Rules page, Click Actions > Create, then set the values.

Attribute

Value

Name

Sourcing rule for Build My Laptop

Organization Assignment Type

Local

Set to:

-

Global when you must specify where to fulfill and ship the sales orders. You don't specify an organization to create supply. Instead, you specify a transfer or buy source. Use buy for a drop ship supplier.

-

Local when you must specify how to create supply and the organization that creates it.

Organization

Seattle Manufacturing

-

-

In the Sourcing Rule Effective Dates area, click Actions > Add Row, then set the start date.

-

In the Effective Start Date area, Click Actions > Add Row, then set the values.

Attribute

Value

Type

Make At

Set to Make At or Buy From for an assemble-to-order model, such as the Build My Laptop model.

You typically make an assemble-to-order item instead of keeping it in inventory. So, you usually don't use Transfer From for the model.

Use Transfer From for a made-to-stock item, such as a component. For example, you don't stock the laptop, but you probably would stock screens for the laptop.

Global Order Promising enables Make At only when you set the assignment type to Local.

Supplier

Supplier Site

Supplier Site Source System

If you create a global rule for a Buy From sourcing type, then you must specify values for these attributes.

If your supply chain includes more than one supplier, then create a separate sourcing rule for each supplier. Add a separate row for each supplier.

Allocation Percent

100

In this example, you add only one row, so specify 100%.

If you add more than one row, then you can allocate demand across sources. For example, if you add a row for Vision Manufacturing and set allocation to 70%, add another row for Vision Distribution and set allocation to 30%, then Promising will use Vision Manufacturing to promise 70% of the orders.

Rank

1

If you add more than one row, then you can specify the rank order to use for sources. For example, if you add a row for Vision Manufacturing and set Rank to 1, add another row for Vision Distribution and set Rank to 2, then Promising will use Vision Manufacturing to promise the order first. If Promising determines that Vision Manufacturing can't fulfill the order, then Promising will consider Vision Distribution.

Shipping Method

Global Order Promising disables Shipping Method for a local rule. You can't edit it. Leave it empty for a global rule.

If you set a value for a global rule, you might get an error.

The value provided for the Shipping Method attribute is invalid.Don't set shipping method in this context because it specifies where supply originates, not how to ship it to the customer.

Exclude for Options and Option Classes

Exclude options and option classes when promising a sales order. Exclude them for a Make At or a Buy From sourcing type.

For example, exclude an item from planning when you know your source can't make it because it includes toxic chemicals that the source isn't authorized to handle, or your company limits production to only one specific site.

For another example, assume you know Seattle Manufacturing created a large oversupply of the CTO_474100 screen option class from a prior marketing campaign. You already know supply is available. To improve planning performance, you decide to exclude it from planning.

-

Click Save > Save and Close.

-

Assign your sourcing rule.

-

Click Tasks > Manage Assignment Sets.

-

On the Manage Assignment Sets page, click Actions > Create.

-

On the Create Assignment Set page, set the values.

Attribute

Value

Name

Assignment Set for Sourcing Rules

Catalog

GOP_Catalog

Use the same catalog that you use for your model in the Product Information Management work area and in your available-to-promise rule.

-

-

Click Actions > Add Row, then set the values.

Attribute

Value

Assignment Level

Item

Note

-

Promising fulfills your sales order only from the source that you assign to the assignment set.

-

Assign at least one sourcing rule at the global level so Global Order Promising can use it to identify a ship-from location. If you don't, then your users must specify the warehouse in every sales order.

-

You must use the same ship-from and source in a configure-to-order make flow.

Item

CTO_474000

Assign your model. In this example, CTO_474000 is the Build My Laptop model.

Sourcing Type

Sourcing Rule

Sourcing Rule or Bill of Distribution

Sourcing rule for Build My Laptop

-

For details, see Sourcing Rule.

Add More Assignments

You can add more than one sourcing rule and assign them differently. Global Order Promising offers you a wide range of choices.

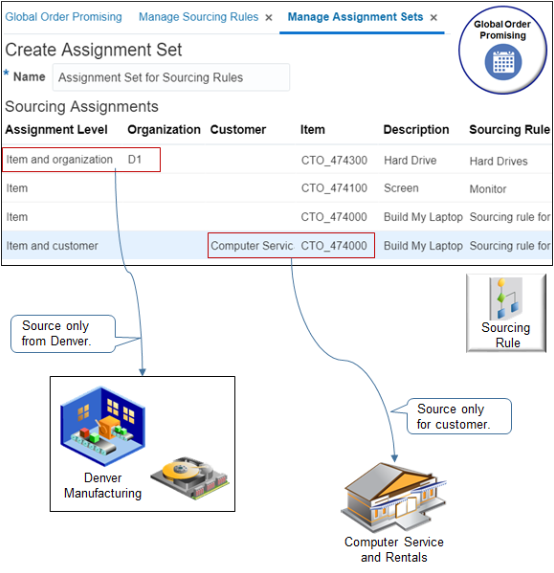

For example, assume you create three different sourcing rules and assign them differently according to item, organization, and customer.

-

Assign the CTO_474000 Build My Laptop item, which is the model, to Sourcing rule for Build My Laptop.

-

Assign the CTO_474000 to Sourcing rule for Build My Laptop only if the customer is Computer Service and Rentals.

-

Assign the CTO_474300 Hard Drive, which is an option class, to the Hard Drives sourcing rule, which is a rule you set up that's optimized to source hard drives.

-

Assign the CTO_474100 Screen, which is an option class, to the Monitor sourcing rule, which is a rule you set up that's optimized to source monitors. Source the CTO_474100 only from D1 Denver Manufacturing when running the sourcing rule.

If you add more than one assignment, then Global Order Promising considers the sourcing rule you set for the most detailed assignment level first. Here's a list of assignment levels that you can use, listed from least detailed to most detailed. For example, Region is more detailed than Global. If you add a global assignment and a regional assignment, then planning runs the regional assignment first, then the global assignment.

-

Global

-

Region

-

Demand class

-

Customer

-

Customer and customer site

-

Category

-

Category and region

-

Item

-

Category and demand class

-

Category and customer

-

Category and customer site

-

Item and region

-

Item and demand class

-

Item and customer

-

Item and customer site

For details, see Set Your Assignment Levels and

Consider Your Sourcing Hierarchy and Assignment Set Hierarchy.Guidelines

Make sure you:

- Assign an ATP rule to each option, option class, required item, and each item in the model's structure.

- Collect the model's structure and all of the structure's child items.