Add Lead Time So You Can Pick and Pack

Use the Pick and Pack Lead Time attribute to add flexibility between the date when supply becomes available at your fulfillment organization and the time when you ship it.

You can add lead time to your scheduled shipment date and scheduled delivery date. Use the lead time to do various activities, such as label and package your item, or prepare the shipment.

Oracle Global Order Promising typically schedules order lines to ship on the day that supply becomes available at the fulfillment location. It delays fulfillment only if it receives an availability check or a scheduling request on the same day that it must ship and after the value in the network model's Order Shipment Cutoff Time attribute.

You might need more time to package and label the item, arrange for transportation, or do quality checks before you ship. You can add extra pick and pack lead time for these activities and you can adjust that time according to the fulfillment organization, carrier, and destination. The lead time that you specify will offset the promised shipment and delivery date for each order line.

Use this feature to realize these benefits:

- Include the time that you need to package and label your shipment, and to prepare for transportation in your promising calculations.

- Offset lead times before you ship and at different levels of your network to meet your specific requirements.

- Add pick and pack lead time to your available-to-promise, buy, make, or transfer supply.

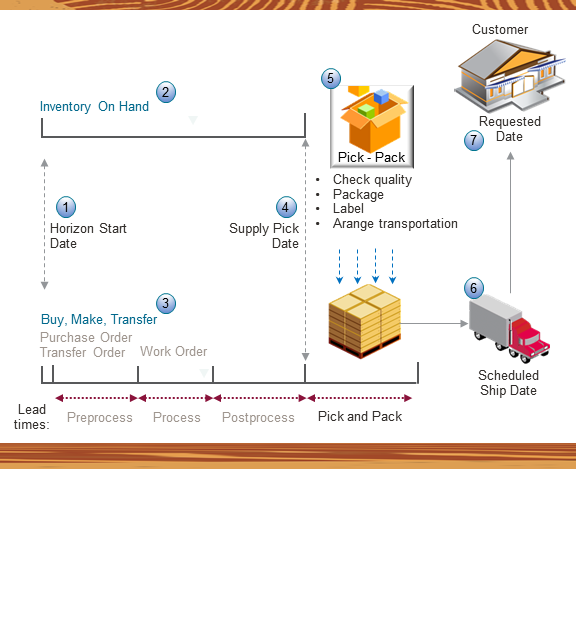

Here’s a summary of how it works.

Note

- Start the promising horizon. The promising horizon is the number of days that Promising considers when it promises your item, such as the number of days to look at in your calendar or in the lead time, the availability for the item's supply, resources, supplier capacity, and so on. For more about the horizon, see Manage Promising Profiles.

- If you’re using supply that’s already on hand in inventory, then Promising sets the Supply Pick Date to the date when it finds that supply is available in inventory and ready to pick.

- If you’re using a buy or transfer flow, then Promising applies your preprocessing lead time, processing lead time, and postprocessing lead time to determine the Supply Pick Date. If you’re using a make flow, then Promising applies your processing and postprocessing lead times. Either way, Promising uses your organization’s calendar to help determine the Supply Pick Date.

- The Supply Pick Date indicates the earliest date that supply is available to pick.

- Promising uses the value that you set in Pick and Pack Lead Time attribute to determine how much time to add so you can pick and pack the item. You can use this time for a variety of reasons according to your specific requirements, such as to do a quality assurance process, package and label the item, arrange for special transportation, and so on.

- Promising calculates the scheduled ship date as the Supply Pick Date plus the

pick and pack lead time.

Promising also considers the transit time needed to ship the item between the Scheduled Ship Date and the Scheduled Arrival Date in the usual way.

- You ship the item to your customer so it arrives by the Requested Date on the sales order.

Note that you can’t view the Supply Pick Date on the sales order. Instead, use the Check Availability page to view it.

Try It

- Make sure you have these privileges.

- Schedule Fulfillment Line (MSP_SCHEDULE_ORCHESTRATION_ORDER_FULFILLMENT_LINE_PRIV)

- Edit Supply Network Model (MSC_EDIT_SUPPLY_NETWORK_MODEL_PRIV)

- View Supply Network Model (MSC_VIEW_SUPPLY_NETWORK_MODEL_PRIV)

- Go to the Plan Inputs work area, then click Tasks > Maintain Supply Network Model.

- On the Maintain Supply Network Model page, click Interlocation Shipping Networks.

- Search for and open your network.

- Enter a whole number in the Pick and Pack Lead Time attribute.

- Click Save.

Guidelines

- Use a whole number in the Pick and Pack Lead Time attribute. The number represents days. For example, if you set it to 2, then you’ll have 2 days to pick and pack.

- If the value in the network model's Order Shipment Cutoff Time attribute applies at run time, then Promising will apply the value that you set in the Pick and Pack Lead Time attribute over and above the shift that happens because of that cutoff time.

- If you do a lot of planning during fulfillment, you might find that the Pick and Pack Lead Time attribute is most useful in your make to stock flow. For details, see Make to Stock Flow.

- If you promise according to the horizon’s end date or the infinite time fence, then Promising will consider the last open date that’s available on the calendar as the Supply Pick Date, and will offset the Scheduled Ship Date after this end date. For background, see Manage Supply After the Promising Horizon Expires.

You can set a value in the Pick and Pack Lead Time attribute on the Interlocation Shipping Networks tab, the Carriers tab, and the Organization tab. If you set it on more than one of these tabs, then Promising uses this priority to determine which value to apply:

- Ship-from organization, plus the shipping method (carrier plus the service level plus the transportation mode), plus the destination.

- The carrier.

- The organization.

You can also use these file-based data import templates to import the Pick and Pack Lead Time attribute:

- ScpInterLocaitonShipMethodsImportTemplate.xlsm

- ScpCarrierImportTemplate.xlsm

- ScpOrganizationImportTemplate.xlsm

You can use this feature with:

- Different types of supply, such as on hand, transfer orders, purchase orders, or work orders

- In your back-to-back flow

- Assemble-to-order configured items

You can't use this feature with:

- A drop shipment

- Demand for a work order component that comes from your bill of resources

Supply Pick Date

Promising uses the Supply Pick Date on the sales order to indicate when supply is available. Promising uses it to calculate the Scheduled Ship Date:

- Scheduled Ship Date equals Supply Pick Date plus Pick and Pack Lead Time

| If Supply Is | Then Supply Pick Date Is |

|---|---|

| Currently in inventory |

Date when you can pick supply from inventory. |

| Buy, make, or transfer |

Date when supply becomes available after postprocessing lead time. For background, see Set Postprocessing Lead Times. |

Promising calculates the Scheduled Ship Date in the shipping organization’s local time zone.

| Current Date | Requested Date | Supply Type | Pick and Pack Lead Time | Supply Pick Date | Scheduled Ship Date |

|---|---|---|---|---|---|

| Day 0 | Day 30 | In inventory | 2 | Day 28 | Day 30 |

| Day 0 | Day 30 | Buy, make, or transfer | 2 | Day 28 | Day 30 |

| Day 0 | Day 0 | In inventory | 2 | Day 0 | Day 2 |

For example, assume:

- Today is day 0.

- The requested date is 30 days from today.

- Supply is currently available in inventory.

- You set the Pack and Lead Time attribute to 2.

Promising will set the Supply Pick Date attribute to 28 days from today, and the Scheduled Ship Date attribute to 30 days from today.

Supply’s Currently Available in Inventory

If the supply needed to meet demand is currently available in inventory, and:

| Is There Enough Time Between Current Date and Requested Date for Pick and Pack? | Promising Will |

|---|---|

| Yes | Calculate the Supply Pick Date attribute on the sales order so it meets the requested date. |

| No | Move the scheduled ship date to a later date so there’s enough time to pick and pack. |

Consider some examples:

| Current Date | Requested Date | Pick and Pack Lead Time in Days | Supply Pick Date on Sales Order | Scheduled Ship Date |

|---|---|---|---|---|

| March 31 | April 10 | 5 | April 5 | April 10 |

| April 8 | April 10 | 5 | April 8 | April 13 |

| April 10 | April 10 | 5 | April 10 | April 15 |

Assume:

- Today is March 31.

- The Requested Date is April 10.

- The Pick and Pack Lead Time is 5 days.

There’s enough time between today and the Requested Date to accommodate the Pick and Pack Lead Time, so Promising sets the Supply Pick Date to April 5 and the Scheduled Ship Date to April 10.

Capable-to-Promise

Assume you’re using a capable-to-promise flow, and you have these dates:

| Current Date | Quantity | Requested Date | Processing Lead Time | Postprocessing Lead Time | Pick and Pack Lead Time |

|---|---|---|---|---|---|

| May 22 | 50 units | May 31 | 5 days | 1 day | 2 days |

To meet this demand, Promising will recommend that your flow creates some buy, make, or transfer supply. For this example, assume it recommends this schedule:

| Status | May 22 | May 23 | May 24 | May 25 | May 26 | May 27 | May 28 | May 29 | May 30 | May 31 |

|---|---|---|---|---|---|---|---|---|---|---|

| Start work order | - | Today | - | - | - | - | - | - | - | - |

| Production complete | - | - | - | - | - | Today | - | - | - | - |

| Pick Date | - | - | - | - | - | - | Today | - | - | |

| Pick n Pack | - | - | - | - | - | - | - | Today | Today | |

| Scheduled Ship Date | - | - | - | - | - | - | - | - | - | Today |

Here’s what Promising does:

- Allows 5 days processing to finish production for the work order, so production for the work order starts on May 23 and ends on May 27.

- Sets the Pick Date immediately after postprocessing is done, which is May 28.

- Allows 2 days, May 29 to May 30, for pick and pack.

- Sets the Scheduled Ship Date to May 31.

For background, see Guidelines for Using Lead Time Mode.

Shipment Cutoff Time

If the current time happens after the cutoff time, then Promising will add one day to the Scheduled Ship Date.

Consider these examples:

| Current Date | Current Time | Cutoff Time | Requested Date | Shift to Next Open Day? | Due Date for Buy, Make, or Transfer Order | Supply Pick Date on Sales Order | Pick and Pack Lead Time in Days | Scheduled Ship Date |

|---|---|---|---|---|---|---|---|---|

| Day 0 | 7 PM | 5 PM | Day 0 | Yes | Day 0 | Day 1 | 2 | Day 3 |

| Day 0 | 7 PM | 5 PM | Day 10 | No | Day 10 | Day 10 | 2 | Day 12 |

| Day 0 | 4 PM | 5 PM | Day 15 | No | Day 10 | Day 13 | 2 | Day 15 |

| Day 0 | 3 PM | 5 PM | Day 0 | No | Day 0 | Day 0 | 2 | Day 2 |

For example, assume you set the Pick and Pack Lead Time attribute to 2, and:

- Today is day 0.

- The current time is 7 PM, the cutoff time is 5 PM, so Promising will move the scheduled ship date to the next open day. For background, see Use Cutoff Times to Control Your Shipments.

- The requested date is today.

Promising will set the:

- Supply Pick Date attribute on the sales order to day 1.

- Scheduled Ship Date attribute on the sales order to day 3, which is the Supply Pick Date plus the Pick and Pack Lead Time.