Back-to-Back Supply Creation Flows

You can set up Oracle Fusion Cloud applications that support back-to-back fulfillment to trigger supply creations flows (buy, make, transfer, and on hand) after a sales order is entered and scheduled.

Each variant of the back-to-back flow differs in the supply document that's created and the supply execution application in which the document is created. Depending on the source of the item, supply is provided from manufacturing, procurement, or inventory. Then, after the supply is received into the fulfillment warehouse, the back-to-back order is ready for shipment to your customer.

The following table describes the supply creation flows and associated supply document supported for each flow when using back-to-back fulfillment.

|

Supply Creation Flow |

Supply Document |

Description |

|---|---|---|

|

Buy |

Purchase Order |

Procurement from an external supplier. |

|

Make |

Work Order |

Production or assembly at an internal manufacturing location. |

|

Transfer |

Transfer Order |

Transfer from another warehouse. |

|

On-hand Available |

Request Reservation Only |

Reservation of on-hand supply (in cases where on hand available in the fulfillment warehouse). |

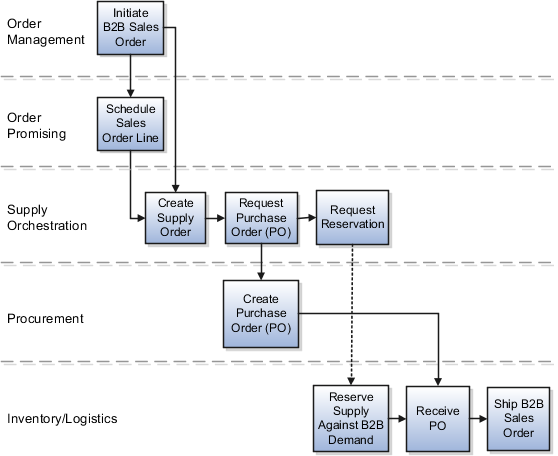

Back-to-Back Supply Creation Buy Flow

The supply document for a back-to-back buy flow is a purchase order. Based on supply recommendations from Oracle Global Order Promising, a purchase order is created and reserved against the sales order. When the purchase order is received by the supplier, on hand is created to ship out the back-to-back sales order.

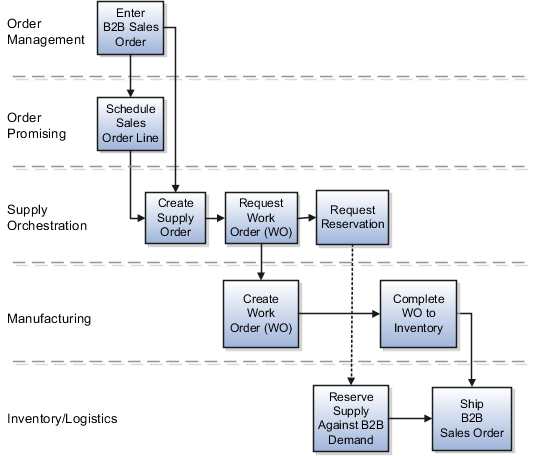

Back-to-Back Supply Creation Make Flow

The supply document for a back-to-back make flow is a work order. As soon as the work order is created in Oracle Fusion Cloud Manufacturing, it's tied to the back-to-back sales order in the form of a reservation in inventory. The work order goes through the regular production process and the work order completion transaction issues finished goods to inventory.

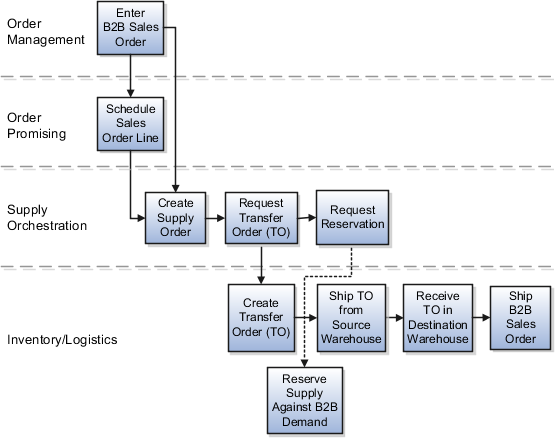

Back-to-Back Supply Creation Transfer Flow

The supply document for a back-to-back transfer flow is a transfer order. The transfer order is created in inventory and reserved against the back-to-back sales order. When the transfer order is ready to be fulfilled, an interorganization shipment moves goods from the source organization to the destination organization. An interorganization receipt in the destination organization (which is also the fulfillment warehouse on the back-to-back sales order) creates on hand to fulfill the sales order.

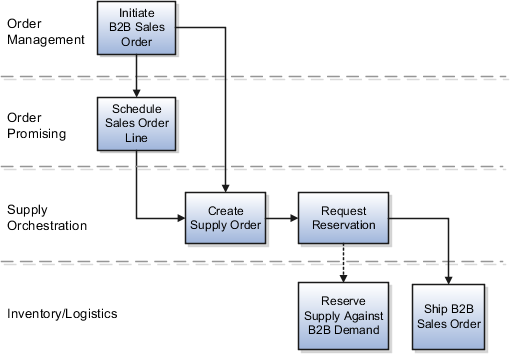

Back-to-Back Supply Creation On-Hand Flow

The back-to-back on-hand available (ATP) flow is the simplest in terms of the number of steps that constitute the flow. This flow occurs where on hand supply is available in the fulfillment warehouse for the ordered back-to-back item at the time of order promising. Because on-hand goods already exist in the form of on hand, Oracle Supply Chain Orchestration directly sends a request to reserve the on hand quantity against the back-to-back sales order. You can ship the sales order immediately after the reservation is created.