Consume Resources Only After Components Are Available

Set up Promising so it starts consuming resources only after your factory has all the components it needs to begin manufacturing. The component's availability will determine the manufacturing start date, resulting in a more realistic promise date.

A manufacturing resource might need to have materials and components on hand in inventory before it starts operations. To prevent unplanned idle time, you can choose to delay the resource's consumption date until after the components and materials are available.The component's availability will determine the manufacturing start date, resulting in a more realistic promise date.

Use this feature when you need promising results that consider your components' availability first, and then your resources' availability, instead of considering component and resource availability at the same time.

Lead Time

The component that has the longest lead time in your bill of resources helps to determine manufacturing's start date. Here's how Promising uses lead time with this feature:

- Uses the postprocessing lead time to help calculate the lead time offset.

- Makes sure the start date for each resource happens on or after the component's start date.

- Makes sure the lead time for each resource results in a manufacturing end date that meets the sales order's due date.

Creating the bill of resources doesn't include the processing lead time for a critical resource's parent assembly when it calculates the lead time offset. This helps to make sure each resource's end date aligns with manufacturing's end date.

For background details, see:Examples

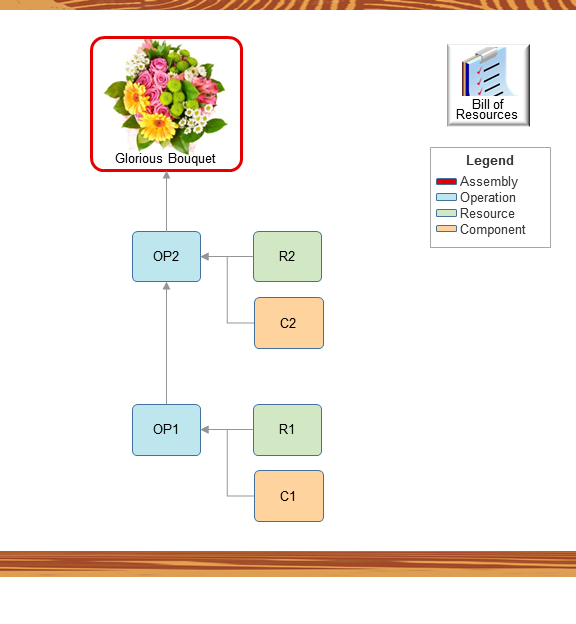

Assume your bill of resources has this hierarchy:

Assume:

- The Create Bills of Resources scheduled process uses this hierarchy. Promising considers only the resources and components. It doesn't consider the operations.

- Today's date is April 1.

- The lead time for C1 is 10 days, and it's also 10 days for C2.

- R1 consumes 2 hours to create 1 unit.

- R2 consumes 3 hours to create 1 unit.

Specify Lead Time for Components, No Lead Time for Resources, and Don't Constrain Availability

Assume:

- April 15 is the requested date for sales order SO1.

- Postprocessing lead time is 0.

- Resource lead times are 0 in the bill of resources.

Promising will use data from the bill of resources and SO1's quantity to calculate the component quantities and resource quantities that manufacturing needs to build the Glorious Bouquet. Assume you need a quantity of 10 bouquets.

Promising uses the bill of resources to determine the quantities that manufacturing will need to build 10 bouquets for sales order SO1 according to the lead times:

| Components and Resources | Lead Time Days in Bill of Resources | Quantity Manufacturing Will Need |

|---|---|---|

| C1 | 10 | 10 |

| C2 | 12 | 20 |

| R1 | 0 | 50 hours |

| R2 | 0 | 20 hours |

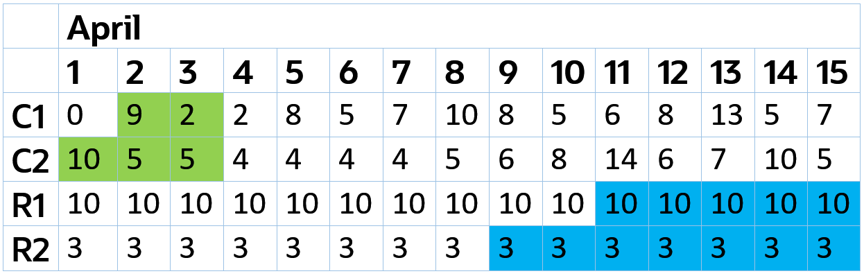

Consider this availability:

where

- Green is component consumption.

- Blue is resource consumption.

- Available quantities are cumulative, counting in reverse. For example, a quantity of 20 is available on April 3 for C2 (5 on April 3, plus 5 on April 2, plus 10 on April 1).

Here's how Promising determines those consumption dates:

- Sets the requested date to April 15.

- Sets manufacturing's end date to April 15, which is the due date minus the bouquet's postprocessing lead time.

- Determines manufacturing's start date. Promising starts at April 15 and works

backward to find the earliest manufacturing start date that it can use and still

meet the lead time requirements for the components and resources:

- Identifies the component or resource that has the largest lead time. C2 has the largest lead time, which is 12 days.

- Sets manufacturing's start date to April 3 (April 15 minus C2's 12 day lead time).

- Makes sure components are available on April 3. Manufacturing needs a quantity of 10 for C1 and a quantity of 20 for C2. In this example, a cumulative quantity of 11 is available for C1 on April 3, and a quantity of 20 is available for C2, so we're good to go.

- Makes sure resources are available from April 3 through April 15. Manufacturing needs 50 hours of R1, and 20 hours of R2. Resource lead times are zero, and the end date to consume resources is April 15. R1 has 130 hours available on April 15, and R2 has 39 hours available, so there's enough cumulative resource hours available on April 15 to meet demand.

- If Promising found that manufacturing didn't have the quantity it needed for each component and resource, then it would use the next day as manufacturing's end date, and try again.

- Finalizes the result:

Attribute Day Manufacturing Start Date April 3 Manufacturing End Date April 15 C1 and C2 Start Date April 3 R1 Start Date April 11 R2 Start Date April 9 R1 End Date and R2 End Date April 15 Scheduled Ship Date April 15 (on time)

Specify Lead Time for Components and Resources, and Don't Constrain Availability

Assume:

- April 15 is the requested date for sales order SO2.

- Postprocessing lead time is 0.

Promising will use data from the bill of resources and SO2's quantity to calculate the component quantities and resource quantities that manufacturing will need to build the bouquet. Assume you need a quantity of 10 bouquets.

Here are the quantities that Promising calculates manufacturing will need to build 10 bouquets for sales order SO2 according to the lead times:

| Components and Resources | Lead Time Days in Bill of Resources | Quantity Manufacturing Will Need |

|---|---|---|

| C1 | 10 | 10 |

| C2 | 12 | 20 |

| R1 | 13 | 50 hours |

| R2 | 9 | 20 hours |

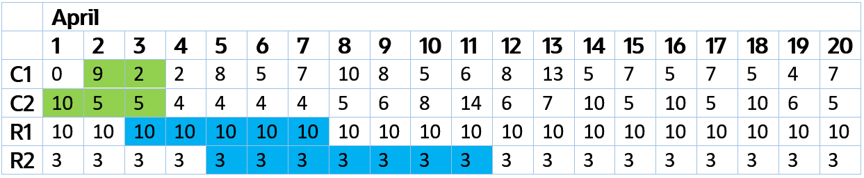

Consider this availability:

Here's how Promising determines those consumption dates:

- Sets the requested date to April 15.

- Sets manufacturing's end date to April 15, which is the due date minus the bouquet's postprocessing lead time.

- Determines manufacturing's start date. Promising starts at April 15 and works

backward to find the earliest manufacturing start date that it can use to meet

the lead time requirements for the components and resources:

- Identifies the component or resource that has the largest lead time. R1 has the largest lead time, which is 13 days.

- Sets manufacturing's start date to April 2 (April 15 minus R1's 13 day lead time).

- Makes sure components and resources are available on April 2. Manufacturing needs a quantity of 10 for C1. However, C1 only has a cumulative quantity of 9 on April 2, so Promising moves on to the next day and tries again.

- In the next iteration, Promising sets manufacturing's end date to April 18 and R1's end date to April 5 (April 18 minus R1's 13 day lead time). R1 has enough capacity to meet the required 50 hours of demand, and Promising calculates R1's start date as April 1. However, C1 has 0 quantity and C2 only has a quantity of 10 on April 1, so Promising discards the results and moves on to the next day.

- Promising iterates through this process until it finds a date that meets manufacturing's demand for components and resources. For each iteration, it applies the lead times and checks availability for each component and resource to see whether it can meet demand for manufacturing's end date and start date.

- After a few more iterations, Promising:

- Sets manufacturing's end date to April 20.

- Sets R1's end date to April 7 (April 20 minus R1's 13 day lead time), and R1's start date to April 3.

- Sets R2's end date to April 11 (April 20 minus R2's 9 day lead time).

- Confirms that C1 and C2 both have enough quantity on April 3 to start

production, so it finalizes the result:

Attribute Day Manufacturing Start Date April 3 Manufacturing End Date April 20 C1 Start Date and C2 Start Date April 3 R1 Start Date April 3 R1 End Date April 7 R2 Start Date April 5 R2 End Date April 11 Scheduled Ship Date April 20 (5 day delay)

Specify Lead Time for Components and Resources, and Constrain Availability

Assume:

- April 10 is the requested date for sales order SO3.

- Postprocessing lead time is 0.

Here are the quantities that Promising calculates manufacturing will need to build 10 bouquets for sales order SO3 according to the lead times:

| Components and Resources | Lead Time Days in Bill of Resources | Quantity Manufacturing Will Need |

|---|---|---|

| C1 | 5 | 10 |

| C2 | 2 | 20 |

| R1 | 5 | 50 hours |

| R2 | 3 | 20 hours |

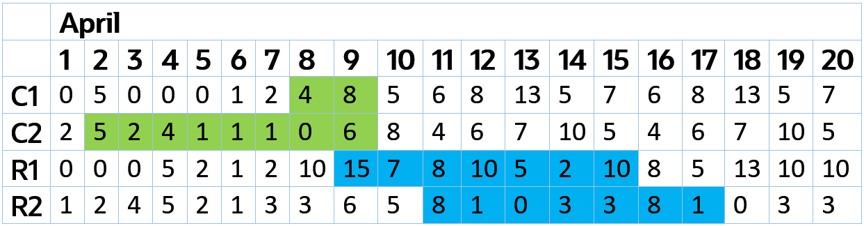

Consider this availability:

- Sets the requested date to April 10.

- Sets manufacturing's end date to April 10, which is the due date minus the bouquet's postprocessing lead time.

- Determines manufacturing's start date. Promising starts at April 10 and works

backward to find the earliest manufacturing start date that it can use to meet

the lead time requirements for the components and resources:

- Identifies the component or resource that has the largest lead time. R1 has the largest lead time, which is 5 days.

- Sets manufacturing's start date to April 5 (April 10 minus R1's 5 day lead time).

- Makes sure components and resources are available on April 5. Manufacturing needs 50 hours of R1, and 20 hours of R2. However, R1 only has a cumulative quantity of 7 hours on April 5, and R2 only has a cumulative quantity of 14 hours on April 5, so Promising moves on to the next day and tries again.

- Iterates through this process. Eventually, Promising sets manufacturing's end date to April 16, which results in manufacturing's start date of April 11, and an R1 start date of April 4. Resources are available on April 4 but components aren't. Manufacturing needs a quantity of 10 for C1 and 20 for C2. However, C1 only has a cumulative quantity of 5 on April 4, and C2 only has a quantity of 12, so Promising continues to iterate the process.

- After a few more iterations, Promising sets manufacturing's end date to

April 20, which results in manufacturing's start date of April 15, and

an R1 start date of April 9. C2's start date on April 9 has enough

quantity to meet demand. All the components and resources that

manufacturing needs are available, this iteration meets the lead time

requirements, so Promising finalizes the result:

Attribute Day Manufacturing Start Date April 9 Manufacturing End Date April 20 C1 and C2 Start Date April 9 R1 Start Date April 9 R1 End Date April 15 R2 Start Date April 11 R2 End Date April 17 Scheduled Ship Date April 20 (10 day delay)

Guidelines

- To use this feature, go to the Order Promising work area, click Tasks > Order Promising Options, then add a check mark to the Consider Resources After Components Are Available option.

- Manufacturing can begin building the assembly item on or after the date that Promising sees availability for all components.

- Promising applies the same logic with alternate resources or substitute components. Promising will use the primary, alternate, or substitute to make sure it promises the sales order on time or with minimum delay.

- If you need slightly faster performance and less accurate promising results, such as when you use a bill of resources with critical components and resources that skip levels of the hierarchy, then don't use this feature. You can continue to promise according to the default behavior.

Bill of Resources

- Promising marks each subassembly, component, and resource that the factory needs to build the final item in your bill of resources. This makes sure Promising considers each of these subassemblies, components, and resources.

- If you use file-based data import (FBDI) to import your bill of resources, then Promising uses the lead times that you specify in the import file.

- You don't have to rerun the Create Bills of Resources scheduled process each time you enable or disable this feature.

- The Create Bills of Resources scheduled process uses your postprocessing lead time. In a future release, you will be able to create an equation that uses a different lead time, such as fixed lead time, plus quantity, multiplied by variable lead time.

Make a Subassembly Critical

If your bill of resources includes more than one organization, and if it has a subassembly that isn't critical and that belongs to an upstream organization, then your components or resources might have longer lead times, and that might lead to a later promise date.

Assume a resource is available in the manufacturing organization, the component for that resource comes from your upstream organization, and that component has a long transit time. This could result in a component's lead time in the bill of resources that's longer than the resource's lead time. Promising might move the promise date to a later date until it meets the component's lead time requirements. To avoid this scenario, make the subassembly item as critical in the upstream organization, then rerun the Create Bills of Resources scheduled process.

Access Requirements

Make sure you have these privileges:

- Schedule Fulfillment Line (MSP_SCHEDULE_ORCHESTRATION_ORDER_FULFILLMENT_LINE_PRIV)

- Edit Bills of Resources (MSC_EDIT_BILLS_OF_RESOURCES_PRIV)

- View Bills of Resources (MSC_VIEW_BILLS_OF_RESOURCES_PRIV)