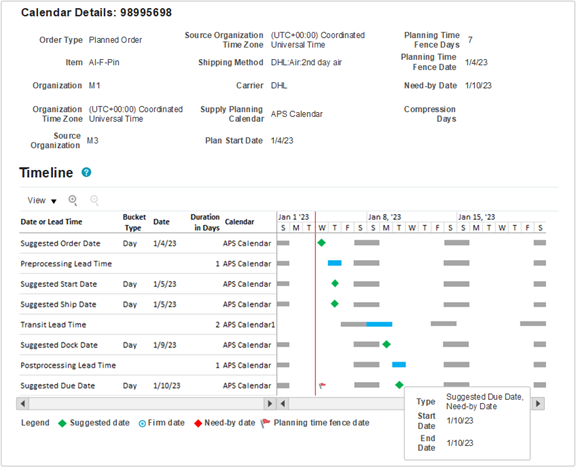

View Calendar Details Example: Planned Transfer Order

This example describes a planned transfer order in an unconstrained plan.

You can tell it’s a transfer order because Source Organization and Source Organization Time Zone fields are displayed in the header section. This is an unconstrained plan. If this were a constrained plan, there would be two additional fields displayed in the header section as well: Earliest Start Date and Latest Start Date.

When looking at the Gantt chart of a transfer order, the Processing Lead Time row isn't displayed. Processing Lead Time doesn’t factor into the scheduling of a transfer order (planned or otherwise) because the transfer order only accounts for the transferring of the supply from the source organization to the destination organization. The processing time required at the source organization is accounted for on the applicable buy or make order.

The red vertical line in the Gantt chart represents the plan start date, which is also shown in the header field. This line is only visible when the plan start date is within the visible portion of the Gantt window.

Planning uses backward scheduling to calculate supply dates, so we’ll analyze the dates starting from the Suggested Due Date (the last row).

| Date or Lead Time Row | Value | Explanation |

| Suggested Due Date | January 10 |

In this example, the Suggested Due Date is the same as the Need-by Date. Because unconstrained planning schedules supplies based on Need-by Date, it’s common that both dates are the same. When milestone dates overlap, the suggested date is always displayed on top in the Gantt chart. If you hover over the Suggested Due Date milestone, you can see that both the Need-by Date and Suggested Due Date are on January 10. The Need-by Date is also displayed in the header section for quick reference without having to hover. If needed, planning will move the Suggested Due Date out so that it’s on or after the Planning Time Fence Date. In this case, the Planning Time Fence Date is January 4 (the same as the Plan Start Date), so there's no need to move the Suggested Due Date out. The calendar used in calculating the Suggested Due Date is the Destination Organization Manufacturing Calendar. In this example, the calendar used is APS Calendar, which has Saturdays and Sundays as nonworking days, represented by gray bars in the Gantt chart. Planning always ensures that the Suggested Due Date is on a working day, however, a planner may firm the order on a nonworking day. If the order is firmed, the Gantt chart will display the Suggested Due Date using the firm date icon (a blue circle), in place of the regular green diamond icon. The planning bucket type for this date and all other dates is day. This lets you know that the Suggested Due Date didn’t get moved to the last working day of the planning bucket, which is what happens when planning in aggregate planning buckets. |

| Postprocessing Lead Time | 1 day |

The Postprocessing Lead Time’s duration in days value comes from the Items page and includes any simulation set overrides. The same calendar used for Suggested Due Date (the Destination Organization Manufacturing Calendar) is also used in calculating Postprocessing Lead Time duration. The end date of the Postprocessing Lead Time is set to the Suggested Due Date. Because the same calendar is being used for both dates, there's no need to make any adjustment to the end date of the Postprocessing Lead Time to ensure it’s on a nonworking day. The start date of the Postprocessing Lead Time is calculated by subtracting the Postprocessing Lead Time from the end date of the Postprocessing Lead Time, only counting the working days. In this example, Postprocessing Lead Time starts and ends on Tuesday, January 8. Because the time associated with the Suggested Due Date is the end of the day (that is, 23:59:00), the 1 day of Postprocessing Lead Time starts at the beginning of the day and goes to the end of the same day. |

| Suggested Dock Date | January 9 |

The calendar used in calculating the Suggested Dock Date is the Destination Organization Receiving Calendar. In this example, the calendar used is APS Calendar. Depending on your setup, the Destination Organization Receiving Calendar might be different from the Organization Manufacturing Calendar, which is used in calculating the Suggested Due Date and Postprocessing Lead Time. The Organization Receiving Calendar can be specific to the receiving organization, or to a carrier and receiving organization combination. In this case, the same calendar used for calculating the Suggested Due Date and Postprocessing Lead Time is also used for calculating the Suggested Dock Date. Therefore, there was no need to adjust the Suggested Dock Date so that it ended up on a working day. The Suggested Dock Date of January 9 matches what we expect to see, given the Postprocessing Lead Time. |

| Transit Lead Time | 2 days |

The Transit Lead Time was derived based on the Shipping Method shown in the header section, which comes from the Interlocation Shipping Methods tab of the Supply Network Model UI. The calendar used in calculating Transit Lead Time is APS Calendar1, which has different working days from other calendars used. Only Sundays through Thursdays are working days for APS Calendar1. The end date of the Transit Lead Time is set to the Suggested Dock Date. If the end date of the Transit Lead Time is not a valid working day on the transit calendar, then the Transit Lead Time end date will be moved earlier, to a working day on the transit calendar. In this example, the Suggested Dock Date, January 9, is a valid working day on the transit calendar, so there’s no need to adjust the end date of the Transit Lead Time. The start date of the Transit Lead Time is calculated by subtracting the Transit Lead Time from the end date of the Transit Lead Time, only counting the working days on the transit calendar. In this example, Transit Lead Time starts at the beginning of the day on Sunday, January 8, and goes through the end of the day on Monday, January 9. |

| Suggested Ship Date | January 5 |

The Source Organization Shipping Calendar is used to calculate the Suggested Ship Date. In this example, APS Calendar was used in calculating the Suggested Ship Date, which has Saturdays and Sundays as nonworking days, represented by the gray bars in the Gantt chart. As you can see, there’s a gap between the Suggested Ship Date and the Transit Lead Time start date. Some of the gap is accounted for because Sunday, January 8, is a nonworking day on the shipping calendar. Why did planning calculate a Suggested Ship Date of Thursday, January 5, and not Friday, January 6? The most likely answer is that the Suggested Dock Date calculated during plan run had a time stamp that wasn’t at the end of the day, and that caused the transit time to actually start on Thursday, January 5 (due to Friday, Saturday, and Sunday being nonworking days). Because the View Calendar Details action calculates lead times after suggested dates are moved to the end of the day, there's a loss of precision from how the planning process calculated suggested dates during plan run. This can result in a gap of one working day being shown in the Calendar Details window. |

| Suggested Start Date | January 5 |

The Source Organization Manufacturing Calendar is used to calculate the Suggested Ship Date. Because the transfer order doesn’t include Processing Lead Time, the Suggested Start Date is set to the same date as the Suggested Ship Date. If the Suggested Start Date is not a valid working day on the Source Organization Manufacturing Calendar, it will be moved earlier to a working day. In this example, the same calendar (APS calendar) was used for calculating both Suggested Ship Date and Suggested Start Date. The Suggested Start Date, January 5, is a valid working day on the Source Organization Manufacturing Calendar, so there's no need to adjust the date. |

| Preprocessing Lead Time | 1 day |

The Preprocessing Lead Time’s duration in days value comes from the Items page and includes any simulation set overrides. Preprocessing Lead Time and Suggested Order Date are used to account for the time it takes the destination organization to raise an order. The Destination Organization Manufacturing Calendar is used in calculating Preprocessing Lead Time. In this case, the calendar used is APS Calendar. The Preprocessing Lead Time end date is set to the Suggested Start Date. If the Suggested Start Date is not a valid working day on the Destination Organization Manufacturing Calendar, it will be moved earlier to a working day. In this example, the Suggested Start Date, January 5, is a valid working day, so there’s no need to adjust the end date of the Preprocessing Lead Time. The start date of the Preprocessing Lead Time is calculated by subtracting the Preprocessing Lead Time from the end date of the Preprocessing Lead Time, only counting the working days. In this example, Processing Lead Time starts at the beginning of the day on January 5 and goes through the end of that same day. |

| Suggested Order Date | January 4 |

The Destination Organization Manufacturing Calendar is used to calculate the Suggested Order Date. In this example, the calendar used is APS Calendar. The January 4 Suggested Order Date matches what we expect to see, given the Preprocessing Lead Time. In this example, the Suggested Order Date just happens to be the same day as the plan start date. This was not a case where the Preprocessing Lead Time needed to be compressed because the plan start date was reached. The supply dates of a transfer order can be analyzed using the View Calendar Details action in the same way that supply dates are analyzed for a planned transfer order. The only difference is that, by default, Preprocessing Lead Time is not applied to transfer orders. After the planned order is released and an order is created on the source system, the ordering process is complete so there’s no need for planning to account for the time it takes to raise an order. As a result, the Preprocessing Lead Time row isn't applied (and therefore it isn't displayed) for transfer orders. When Preprocessing Lead Time isn't applied, the Suggested Order Date is equal to the Suggested Start Date. |