Example of Work Order Scheduling

Work order scheduling behavior for in-house operations and the various scheduling methods are explained using the following example. A plant works continuously in a single 9 hour shift from 8:00 a.m. to 5:00 p.m. on all days of a week. This shift time is interpreted in the plant time zone.

The following table explains a scenario where different resources are available in the plant to manufacture a product A and lists the efficiency percentage, utilization percentage and availability of each resource:

|

Work Center |

Resource Name |

Efficiency Percentage |

Utilization Percentage |

Available 24 Hours |

|---|---|---|---|---|

|

Machine Shop |

CNC Milling Technician QA Inspector |

100% 100% 100% |

50% 100% 100% |

No No No |

|

Assembly Line |

Operator Conveyor Line |

100% 100% |

100% |

No |

|

Packing Line |

Auto Packer |

50% |

100% |

Yes |

All the Conveyor Line resources belonging to Assembly Line work center are unavailable on day 2 from 9:00 am to 11:00 am due to the monthly preventive maintenance schedule. To reflect this in the application, the supervisor defines a work center resource exception.

To manufacture a quantity of 8 each of a product A, the following operations of a work order are used:

Work Order123, with Operation 10: Machining, and Work Center Machine Shop.

The following table lists the details of three different resources:

|

Sequence |

Resource Name |

Required Usage |

UOM |

Assigned Units |

Scheduled |

|---|---|---|---|---|---|

|

10 |

CNC Milling |

2 |

Hours |

1 |

Yes |

|

20 |

Technician |

2 |

Hours |

2 |

Yes |

|

30 |

QA Inspector |

1 |

Hours |

1 |

No |

Work Order 123, with Operation 20: Assembly, and Work Center Assembly Line.

The following table lists the details of two different resources:

|

Sequence |

Resource Name |

Required Usage |

UOM |

Assigned Units |

Scheduled |

|---|---|---|---|---|---|

|

10 |

Operator |

4 |

Hours |

1 |

Yes |

|

10 |

Conveyor Line |

4 |

Hours |

2 |

Yes |

Work Order123, with Operation 30: Packing, and Work Center Packing Line.

The following table lists the details of one resource:

|

Sequence |

Resource Name |

Required Usage |

UOM |

Assigned Units |

Scheduled |

|---|---|---|---|---|---|

|

10 |

Auto Packer |

1 |

Hours |

1 |

Yes |

-

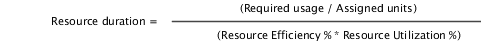

During the scheduling process, the application computes the duration of a resource in the following manner:

-

In operation 10, the resource CNC Milling has a utilization of 50%. This has an effect of extending the usage of this resource by twice its required usage.

-

In operation 10, since the resource sequence number of the resources is different, the resources are scheduled sequentially. In operation 20, since the resources share the same resource sequence number, the resources are scheduled in parallel.

-

The Conveyor resource used in operation 20 is unavailable for 2 hours on day two, and so the application doesn't schedule this resource during that period.

-

In operation 30, the resource Auto Packer has an efficiency of 50%. This has an effect of extending the usage of this resource by twice its required usage.

-

The resource Auto Packer is available 24 hours and so its resource usage is done even if isn't outside the plant shift duration.

Forward Scheduling

If the work order is created using the start date of day 1 at 8:00 a.m., the application forward schedules the work order and computes the completion date as day 1 at 7:00 p.m. The resource duration is displayed in the following chart:

The following figure shows Forward Scheduling with six resources:

If the work order is created using the start date of day 1 at 8:00 a.m., the application forward schedules the work order and computes the completion date as day 1 at 7:00 p.m.

The following table presents the information that has been explained diagrammatically for Forward Scheduling:

|

Operation Sequence |

Resource Sequence |

Resource Name |

Resource Duration |

Scheduled Dates With Explanation |

|---|---|---|---|---|

|

10 |

10 |

CNC Milling |

(2/1)/ (50% *100%) = 4 hours |

Forward Scheduling logic is applied from the first resource of the first operation. The first operation is the Machining operation. Since the work order is being requested to start at 8:00 a.m., the first resource required for this operation is CNC Milling with required resource duration of 4 hours. The CNC Milling resource is scheduled from 8:00 a.m. to 12:00 noon. |

|

10 |

20 |

Technician |

(2/2)/ (100% *100%) = 1 hour |

The Technician performing the task after CNC Milling resource is scheduled from 12:00 noon to 1:00 p.m. |

|

10 |

20 |

QA Inspector |

(0 hours (Since Scheduled= N) |

The QA Inspector has no duration but shares the same resource sequence as the Technician, so the scheduled start and end time is 1:00 p.m. |

|

20 |

10 |

Operator |

(4/1) / (100%*100%) = 4 hours |

The next operation is the Assembly operation. The Operator takes 4 hours to complete the task and is scheduled from 1:00 p.m. to 5:00 p.m. |

|

20 |

10 |

Conveyor Line |

(4/2) / (100%*100%) = 2 hours |

The Conveyor Line resource is used in Assembly operation and is scheduled to start in parallel with the Operator. So the conveyor line operation starts at 1:00 p.m. and ends at 3:00 p.m. |

|

30 |

10 |

Auto Packer |

(2/2) / (50%*100%) = 2 hours |

The Packing operation starts after Assembly operation at 5:00 p.m. and ends at 7:00 p.m. With this, the work order is completed. |

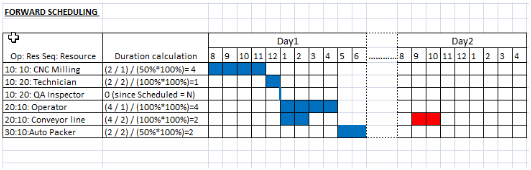

Backward Scheduling

If the work order is created using the completion date of day 2 at 1:00 p.m., the application backward schedules the work order and computes the start date as day 1 at 9:00 a.m. The resource duration is displayed in the following chart:

The following figure shows Backward Scheduling with six resources:

If the work order is created using the completion date of day 2 at 1:00 p.m., the application backward schedules the work order and computes the start date as day at 11:00 a.m.

The following table presents the information that has been explained diagrammatically for Backward Scheduling:

|

Operation Sequence |

Resource Sequence |

Resource Name |

Resource Duration |

Scheduled Dates With Explanation |

|---|---|---|---|---|

|

30 |

10 |

Auto Packer |

(2/2) / (50%*100%) = 2 hours |

Backward Scheduling logic is applied and we start with the last resource of the last operation and compute the start date by scheduling operations in a reverse sequence of forward scheduling. Since the work order is being requested to be completed on day 2 1:00 p.m., and the Auto Packer resource requires 2 hours, Packing operation starts on day 2 at 11:00 a.m. and ends at 1:00 p.m. |

|

20 |

10 |

Conveyor Line |

(4/2) / (100%*100%) = 2 hours |

Next the prior operation Assembly is scheduled. The Conveyor Line resource used in this operation is unavailable for 2 hours on day 2 from 9:00 a.m. to 11:00 a.m., and so the application doesn't schedule this resource during that period. The Conveyor Line resource is used in Assembly operation and is scheduled from 8:00 a.m to 9:00 a.m. on day 2, and 4:00 p.m. to 5:00 p.m. on day 1. |

|

20 |

10 |

Operator |

(4/1) / (100%*100%) = 4 hours |

The Operator working in the Assembly operation takes 4 hours to complete the task and is scheduled from 8:00 a.m. to 11:00 a.m. on day 2, and 4:00 p.m. to 5:00 p.m. on day 1. |

|

10 |

20 |

QA Inspector |

(0 hours (Since Scheduled= N) |

The QA Inspector has no duration but shares the same resource sequence as the Technician, so the scheduled start and end times is 4:00 p.m. on day 1. |

|

10 |

20 |

Technician |

(2/2)/ (100% *100%) = 1 hour |

The Technician performing the Machining operation is scheduled from 3:00 p.m. to 4:00 p.m. on day 1. |

|

10 |

10 |

CNC Milling |

(2/1)/ (50% *100%) = 4 hours |

CNC Milling requires 4 hours and is scheduled from 11:00 a.m. to 3:00 p.m. on Day 1 based on Backward Scheduling. So, the work order starts on day 1 at 11:00 a.m. |

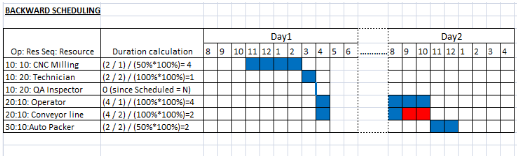

Midpoint Scheduling

If the work order is updated by invoking midpoint scheduling of work order operation 20 such that the operation 20 starts on day 2 at 11:00 am, the application performs midpoint scheduling as displayed in the following chart, such that the work order's start date is day 1 at 3:00 p.m. and completion date is day 2 at 5:00 p.m.

The following figure shows Midpoint Scheduling with six resources:

If the work order is updated by invoking midpoint scheduling of work order operation 20 such that the operation 20 starts on day 2 at 11:00 am, the application performs midpoint scheduling as displayed in the following chart, such that the work order's start date is day 1 at 3:00 p.m. and completion date is day 2 at 5:00 p.m.

The following table presents the information that has been explained diagrammatically for Midpoint Scheduling:

|

Operation Sequence |

Resource Sequence |

Resource Name |

Resource Duration |

Scheduled Dates With Explanation |

|---|---|---|---|---|

|

20 |

10 |

Operator |

(4/1) / (100%*100%) = 4 hours |

Invoking Midpoint Scheduling of work order operation 20, such that operation 20 starts on day 2 at 11:00 a.m. The Operator takes 4 hours to complete the task and is scheduled from 11:00 a.m. to 3:00 p.m. on day 2. |

|

20 |

10 |

Conveyor Line |

(4/2) / (100%*100%) = 2 hours |

All downstream operations are scheduled using Forward Scheduling logic. So, the Conveyor Line resource is used in Assembly operation from 11:00 a.m. to 1:00 p.m. on day 2. |

|

30 |

10 |

Auto Packer |

(2/2) / (50%*100%) = 2 hours |

The Packing operation starts on day 2 at 3:00 p.m. and ends at 5:00 p.m. With this the work order is completed. |

|

10 |

20 |

QA Inspector |

(0 hours (Since Scheduled= N) |

All upstream operations are scheduled using Backward Scheduling logic. So, the QA Inspector has no duration but shares the same resource sequence as the Technician, so the scheduled start and end times is 11:00 a.m. on day 2. |

|

10 |

20 |

Technician |

(2/2)/ (100% *100%) = 1 hour |

Invoking Backward Scheduling, the Technician performing the Machining operation is scheduled from 10:00 a.m. to 11:00 a.m. on day 2. |

|

10 |

10 |

CNC Milling |

(2/1)/ (50% *100%) = 4 hours |

The Technician shift time ends at 11:00 a.m. on day 2. The resource duration required is 4 hours. The CNC Milling resource shift is scheduled from 8:00 a.m. to 10:00 a.m. on day 2 and from 3:00 p.m. to 5:00 p.m. on day 1. This determines the work order start day as day 1 at 3:00 p.m. |

Select the work order scheduling method

The scheduling method is displayed at the work order header for work orders. You can select one of the following two values:

-

Default Scheduling

This scheduling method is the default option when a work order is created through the user interface.

-

User or External Scheduling

When you select this scheduling method, you can schedule or reschedule the work order manually by updating the work order dates, operation dates, and resources dates. Also, the firm check box is automatically selected, and you can optionally deselect the firm flag.

Schedule work orders manually

- Manual update of work order attributes

If you update the work order quantity, then the work order isn't rescheduled. However, the material and resource requirements are recalculated.

If you update the work definition name or date, then the scheduling method is automatically updated as default scheduling and the work order is automatically scheduled. The work order is re-exploded with the details of the new work definition.

- Manual update of work order start and completion dates

You can use this scheduling method only in the user interface. However, the FBDI and REST services continue to work with the default scheduling method.

- Manual update of work order operation start and completion dates

You can manually update the start and completion dates of the work order operations. The unconstrained scheduling won't be invoked if your scheduling method is User or External Scheduling. However, the work order start and completion dates gets synchronized with the earliest operation start date and the latest completion date, if they are outside the work order start and completion date.

- Manual update of work order resource start and completion dates

You can manually update the start and completion dates of the work order resources. The unconstrained scheduling won't be invoked if your scheduling method is User or External Scheduling. However, the work order operation start and completion dates and the work order start and completion dates gets synchronized with the earliest resource start date and the latest resource completion date, if they are outside the work order or operation dates.

During work order execution, if you resequence the operation, then the work order wouldn’t be automatically scheduled if the scheduling method is User or External Scheduling.

Oracle Fusion Cloud Supply Planning, including Production Scheduling will consider manually scheduled work orders during scheduling. If Oracle Supply Planning, including Production Scheduling update the work order dates, Oracle Fusion Cloud Manufacturing will honor the recommendations.