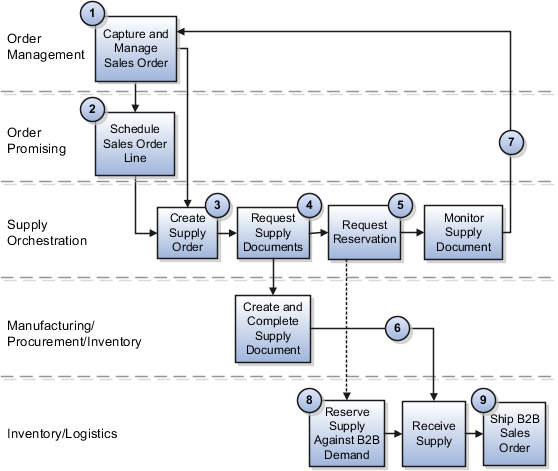

How Back-to-Back Fulfillment Works

The back-to-back process flow is one in which specific sales order demand triggers supply creation and a link is established between the sales order and the supply.

An organization procures goods from an internal or external supplier or source to a specific warehouse from where you can combine those goods with others to create a single shipment to the customer. Back-to-back supply processes are similar to regular supply processes that deliver supply to a warehouse except for one difference; the back-to-back supply is always reserved to an order management fulfillment line.

At a high level, you can think of back-to-back fulfillment as a three-step process:

-

Creation of a customer sales order (source of demand).

-

Creation and fulfillment of supply document (source of supply) to the fulfillment warehouse.

-

Shipment of sales order from the fulfillment warehouse to the customer.

Explanation of Callouts

-

The back-to-back flow begins with order capture. Typically, an order entry specialist enters a customer sales order for an item that's designated for back-to-back fulfillment. After the sales order is entered and scheduled, Oracle Global Order Promising is invoked.

-

Global Order Promising performs two key functions:

-

First, Global Order Promising promises orders for back-back items by choosing the best possible sources across the supply chain, while considering sourcing rules, available-to-promise (ATP) rules, and other constraints.

Note: ATP calculations are currently supported only for discrete manufacturing. -

Second, Global Order Promising releases supply recommendations (or the supply picture) to Oracle Supply Chain Orchestration. These supply recommendations are based on how Global Order Promising pegs supply against the back-to-back demand.

After the sales order fulfillment line is scheduled, Oracle Fusion Cloud Order Management releases the fulfillment line information (or the demand picture) to Supply Chain Orchestration.

-

-

Supply Chain Orchestration processes the demand picture from Order Management and the supply picture from Global Order Promising to create a supply order in Supply Chain Orchestration.

-

Supply Chain Orchestration also triggers the creation of supply documents in the supply execution application. Depending on how sourcing rules are defined and how Global Order Promising sends its supply recommendations, the supply document can be a purchase order in Oracle Fusion Cloud Procurement, a work order in the Oracle Fusion Cloud Manufacturing solution, or a transfer order in Oracle Fusion Cloud Inventory Management.

Note: Back-to-back purchase order creation requires the initiation of a purchase requisition, which is then converted (automatically or manually) to a purchase order. -

Supply Chain Orchestration tracks the creation of the supply document and immediately initiates a reservation request to tie the sales order demand with the supply document.

-

The reservation of supply to demand is made in Inventory Management and ensures that the incoming supply isn't allocated incorrectly or diverted to any other demand source.

Note: Global Order Promising respects the pegging between the supply document and the sales order during subsequent reschedules for the order. -

Supply Chain Orchestration tracks the status of the supply document and sends updates to order management.

-

After the supply is received into stock (purchase order receipt and put away, transfer order receipt and put away, or work order completion), the reservation switches from the supply document to on hand that has been created by the supply document receipt.

-

The sales order is now ready to be shipped to the customer. Order Management requests shipment to the customer and then interfaces with receivables for billing. Supply Chain Orchestration tracks the process until the goods are shipped to the customer.