How Modeling of Entities Work Together in Contract Manufacturing

For contract manufacturing to work in Oracle Fusion Cloud Manufacturing, some of the entities within contract manufacturing are modeled as explained in the following section:

-

Contract manufacturer: Modeled as a regular supplier and supplier site within the Original Equipment Manufacturer's enterprise. Also modeled as an inventory organization within the original equipment manufacturer's enterprise.

-

Contract manufacturing finished good item: Item type is set to Make. The contract manufacturing check box is set to Yes.

-

Contract manufacturing service item: Item type is set to Buy. The contract manufacturing check box is set to Yes.

-

Contract manufacturing finished good item Bill of Material (BOM): Components supplied by the original equipment manufacturer are included in the BOM. The Supply Type of the components supplied by the contract manufacturer is marked as Supplier.The Supply Type for the components that are supplied by the original equipment manufacturer is marked as Push. The contract manufacturing service item is also included as a component in the BOM.

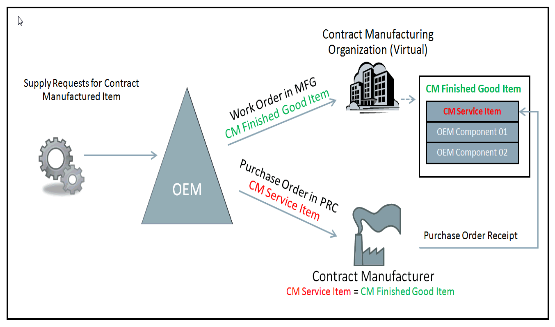

The following figure illustrates how the entities work together in contract manufacturing:

The following figure explains how various entities work together to complete the contract manufacturing flow. It is explained in detail in the topic.

Explanation of how these entities work together in contract manufacturing:

-

The original equipment manufacturer (OEM) receives supply creation requests for a contract manufactured item.

-

After the supply creation request is received, the OEM creates a work order on the contract manufacturing finished good item in the contract manufacturing organization to monitor the manufacturing process in the contract manufacturer's facility. The contract manufacturing organization is a virtual organization that was created in the OEM enterprise representing the contract manufacturer to whom the manufacturing is outsourced.

-

The OEM sends a purchase order on the contract manufacturing service time to the contract manufacturer as part of outsourcing the manufacturing.

-

On receiving the Purchase Order (PO) on the contract manufacturing service item, the contract manufacturer understands that the PO is to manufacture the contract manufacturing finished good item. The contract manufacturer understands this because that person would have mapped the contract manufacturing service item to the contract manufacturing finished good item within their enterprise, based on the agreement with the OEM. This is achieved either by item cross referencing or any other means within their enterprise which is outside the purview of contract manufacturing.

-

After the contract manufacturer completes manufacturing, the contract manufacturing finished good item is stocked in their premises and the contract manufacturer notifies the OEM that production is complete.

-

The OEM initiates a receipt transaction on the PO placed on the contract manufacturer and receives the contract manufacturing service item into the contract manufacturing virtual organization, and completes the tracking work order that was created in the contract manufacturing organization. Because the contract manufacturing service item is one of the components in the Bill of Material (BOM) for the contract manufacturing finished good item, and the contract manufacturing service item is set for backflush or assembly pull, the contract manufacturing service item is auto-consumed into the work order. In addition, the inventory for the contract manufacturing finished good item is created in the contract manufacturing organization and the contract manufacturing service item inventory is decremented from the contract manufacturing organization.