How Outside Processing is Managed and Executed

This topic details the sequence of steps of the process flow for outside processing. There may be variations to the process flow depending on the business offering.

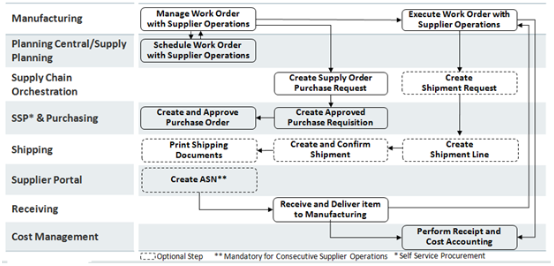

The following image illustrates the process flow of outside processing across product offerings in Oracle Fusion Supply Chain & Manufacturing:

This image explains the various steps involved across products to complete an outside processing flow.

The following steps explain the process flow in a sequential manner:

-

Create and release a work order with supplier operations in Oracle Manufacturing Service. Work orders are scheduled using the unconstrained logic in Oracle Planning Central Service and Oracle Supply Planning Service.

-

When the work order is released, a request is sent to Oracle Orchestration Service to create a purchase requisition. Oracle Orchestration Service in turn creates a supply order and triggers the creation of a purchase requisition in Oracle Self-Service Procurement.

-

An Outside Processing Purchase Order is created in Oracle Fusion Cloud Purchasing Service using the details maintained in the Outside Processing Blanket Agreement.

-

Execute the work order by reporting quantities as completed at the operation prior to the supplier operation. A request is then sent to Oracle Fusion Cloud Orchestration Service to create a Shipment Line. Oracle Orchestration Service in turn creates a Supply Order Line and triggers the creation of a Shipment Line in Oracle Shipping.

-

A Shipment is manually created for the Shipment Line in Shipping which is then confirmed and closed. Based on the options set for the Ship Confirm Rule, the processes to Print Packing Slip and Bill of Lading are initiated automatically.

-

The next step is to create an Advance Shipment Notice (ASN) in the Supplier Portal for the outside processing service item. Goods are received in Oracle Receiving using the ASN and delivered to Oracle Manufacturing Service. For a supplier operation that's not serialization enabled, this results in automatic completion of quantities at the supplier operation.

-

Supplier operations are then managed and tracked in Oracle Manufacturing Service.

-

The receipt, delivery and operation transactions result in receipt and cost accounting in Oracle Cost Management.