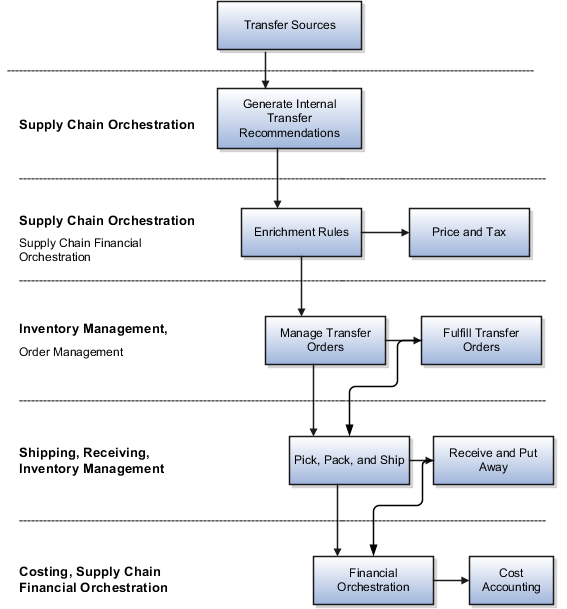

Internal Material Transfer Process Flow

The life cycle of an internal material transfer spans several tasks and products from initiation of the transfer source through the costing and accounting of the transfer. The internal material request and fulfillment process ranges from simple processes to extremely complex processes, spanning multiple legal entities, across geographies, and involving multiple shipment points.

Transfer Sources

You initiate internal material transfers from transfer sources.

This table shows the transfer sources from which you can create internal material transfers.

|

Transfer Source |

Description |

|---|---|

|

Min-max planning |

Automatically create internal material transfers from min-max planning. |

|

Back-to-back |

Automatically create internal material transfers from back-to-back transfers. |

|

Planning |

Automatically create, reschedule, and cancel internal material transfers from planning. |

|

Supply Order web service |

Manually create, update, and cancel internal material transfers through a supply request web service. |

|

Template upload |

Manually create, update, and cancel internal material transfers through a supply request file-based data import spreadsheet template. |

|

Requisitions lines |

Manually create internal material transfers from requisition lines in Self Service Procurement. |

|

Create Supply Request page |

Manually create internal material transfers on the Create Supply Request page which you can access from the Manage Item Quantities page. This allows entry of ad-hoc internal material transfers directly from Inventory. |

Generate Internal Material Transfer Recommendations (Supply Chain Orchestration)

The process starts with creating a transfer source. Multiple automatic and manual transfer sources are supported including min-max planning, back-to-back, spreadsheet upload, Supply Order web service, planning, self-service procurement requisition lines, and the Create Supply Request page from the Manage Item Quantity page.

Sourcing tools enable you to manually create internal material transfer requisition lines in Self Service Procurement and create supply requests from the Manage Item Quantity page. These sourcing tools provide a default source organization and allow access to source organization rankings and available to promise quantities. Oracle Supply Chain Orchestration works with Oracle Global Order Promising and Oracle Inventory Management to identify the source organization rankings based on pre-established rules.

Enrichment Rules (Supply Chain Orchestration)

During the supply creation process, Supply Chain Orchestration evaluates the Supply Execution Documentation Creation Rules to determine if an internal material transfer should be executed using a transfer order or a purchase order.

Manage and Fulfill Transfer Orders (Inventory Management)

A transfer order is created automatically from the various transfer sources. The transfer order represents demand and supply in a single document. Both interorganization and intraorganization transfers are supported by Oracle Inventory Management.

Pick, Pack, Ship, Receive, and Put Away (Shipping, Receiving, and Inventory Management)

You can perform processes such as pick, ship, receive, put away, and return against a transfer order document. Warehouse managers have full visibility to shipments and receipts associated with a transfer order. You can update attributes on a transfer order such as source organization, requested delivery date, and requested quantity.

You can also use self-service receiving for the receiving of requisition sourced transfer orders.

Financial Orchestration (Supply Chain Financial Orchestration)

Oracle Supply Chain Financial Orchestration (SFO) allows the supply chain controller to model financial flows between business units involving different pricing and accounting requirements. The Supply Chain Financial Orchestration framework provides an estimate of the transfer price for creation of transfer orders to transfer goods between internal organizations. Once the transfer price is calculated, Supply Chain Financial Orchestration calls the tax application to determine the tax applicable on the transfer price.

For internal material transfer requisition lines, Self Service Procurement calls Supply Chain Financial Orchestration directly when creating transfer orders to get the estimated price to use for approvals and budgetary control purposes.

Cost Accounting (Cost Management)

Oracle Cost Management has an infrastructure in place to trigger costing and accounting of internal transfers automatically. Internal material transfer transactions such as Transfer Order Shipment and Transfer Order Receipt are interfaced to Cost Management. Trade events are interfaced from Supply Chain Financial Orchestration to Cost Management. Cost Management also provides the ability to analyze the gross margin earned for internal sales transactions separately.