Forecast an Assemble-to-Order Item

Set up a forecast according to your organization for an assemble-to-order item.

-

Use the Planning Central work area to set up the forecast.

-

Create a statistical forecast for an assemble-to-order item. Use shipment history and booking history to do the forecast.

-

Consume the forecast for your model. Each sales order that contains your configured item consumes the forecast.

-

Explode the forecast that remains after the model is done consuming. Generate a production forecast for your option classes and options.

Planning Central displays the forecast for the options, option classes, and child models as a production forecast. It indicates the forecast that remains after planning consumes the forecast for the model that your sales orders needs to fulfill the configured item.

Planning uses the planning percent you set on the class and option to forecast demand. You specify the percent when you set up the structure for the item in the Product Information Management work area.

-

Create supply for your forecast according to organization. Set up a planning sourcing rule that sources components and subassemblies.

-

Planning uses the fixed and variable lead times you set up on the model to offset the production forecast it creates for the options.

Here's an example.

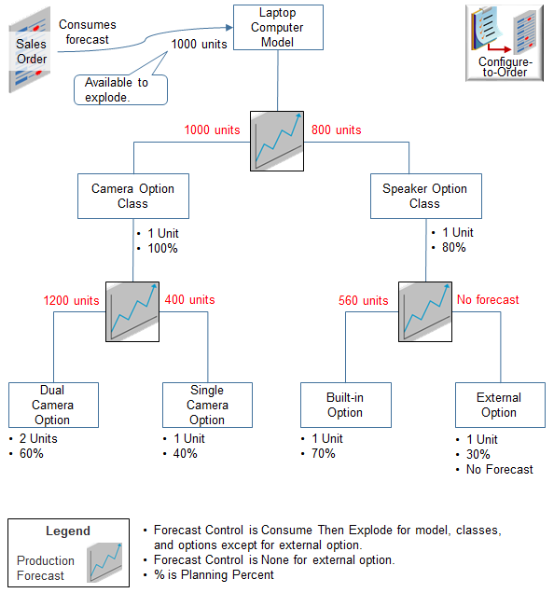

Assume you need organization M1 to manufacture an assemble-to-order model that includes a hierarchy.

-

Laptop Computer Model

-

Camera Option Class

-

Dual Camera Option

-

Single Camera Option

-

-

Speaker Option Class

-

Built-in Option

-

External Option

-

-

Assume your market research indicates you expect.

-

100% demand for the camera. Everybody wants one.

-

60% demand for a dual camera and 40% for a single camera.

-

80% demand for high-fidelity speakers.

-

Of the 80% who want high-fidelity, 70% want built-in speakers, and 30% want external speakers.

Assume you set up the model.

|

Object |

Forecast Control |

Planning Percent |

|---|---|---|

|

Laptop Computer Model |

Consume Then Explode |

Not applicable. |

|

Camera Option Class |

Consume Then Explode |

100 |

|

Dual Camera Option |

Consume Then Explode |

60 |

|

Single Camera Option |

Consume Then Explode |

40 |

|

Speaker Option Class |

Consume Then Explode |

80 |

|

Built-in Option |

Consume Then Explode |

70 |

|

External Option |

None |

30 |

The configured item in the sales order consumes part of the forecast. Planning explodes what's left over according to your set up. Assume 1,000 units are available to explode after the sales order consumes the configured item.

Here's the math.

|

Object |

Math |

|---|---|

|

Camera Class |

The model consumes one unit of the camera class for each laptop. You expect 100% of your customers will want a camera. So planning calculates the production forecast at 1,000.

|

|

Dual Camera Option |

The dual camera option needs two cameras for each laptop, so the model consumes two units. You expect 60% of your customers will choose this option. Planning calculates the forecast at 1,200.

|

|

Single Camera Option |

The single camera option needs only one camera for each laptop, so the model consumes one unit. You expect 40% of your customers will choose this option. Planning calculates the forecast at 400.

|

|

Speaker Class |

The model consumes one unit of the speaker class for each laptop. Assume the speaker class allows your user to choose high-fidelity speakers, either built-in or external. You expect 80% of your customers will want high-fidelity speakers. Planning calculates the forecast at 800.

|

|

Built-in Option |

You need only one set of built-in speakers for each laptop, so the model consumes 1 unit of the built-in option. You expect 70% of your customers will choose this option. Planning calculates the forecast at 560.

|

|

External Option |

You need only one set of external speakers for each laptop, so the model consumes 1 unit of the external option. You expect 30% of your customers will choose this option, but you set the Production Forecast to None for this option. So planning doesn't calculate a forecast. |

Assume you set the fixed lead time for the model to 5 days and the variable lead time to 0. Here's how planning explodes the forecast that's due on day 15.

|

Object |

Production Forecast Date |

Quantity, in Units |

|---|---|---|

|

Model |

Day 15 |

1000, after consuming forecast for the model |

|

Camera Class |

Day 10 |

1000 |

|

Dual Camera |

Day 10 |

1200 |

|

Single Camera |

Day 10 |

400 |

For details, see Forecasting for CTO Products.