Set Up Item Substitution in Order Management

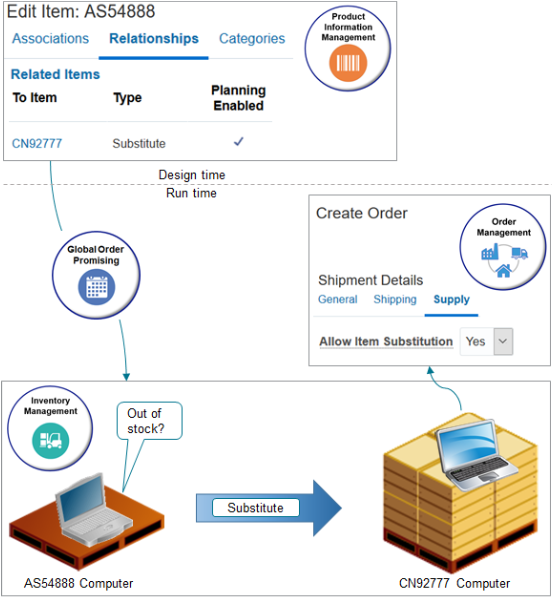

Set up substitution in Order Management so you can use a substitute item to fulfill an order line when the preferred item is out of stock.

You can use the Substitute Item action or the Check Availability action in a fulfillment view of the Order Management work area to substitute an item. You can also use Global Order Promising to substitute an item. This topic describes how to use Global Order Promising.

Note

-

You use the Product Information Management work area to specify the item to substitute at design time.

-

At run time, the Order Entry Specialist creates a sales order in the Order Management work area and clicks Submit.

-

Fulfillment fulfills the item.

-

The scheduling fulfillment task in your orchestration process calls Global Order Promising.

-

Global Order Promising communicates with Inventory Management to determine whether the item is out of stock.

-

If its out of stock, and if the Allow Item Substitution attribute on the sales order is Yes, and if Global Order Promising determines that the substitute item is available, then Global Order Promising sends a recommendation to Order Management to use it, and Order Management uses the substitute to fulfill the order line.

-

Guidelines

-

You can use Visual Information Builder to create a pretransformation rule that sets the default value for Allow Item Substitution to No.

Here's an example rule you can create.

If Order Type is equal to Mixed Orders, then Allow Item Substution is set to NoFor details, see Use Visual Information Builder.

-

You can't specify substitution when you import a source order. Instead, cancel the existing line and add a new one.

-

Don't use substitution to replace an obsolete item. Assume you add memory to the AS54888 and upgrade it to a new item, the AS55000. You have an open sales order that contains the AS54888. Revise the sales order, delete the line that has the AS54888, and add a new line that has the AS55000.

- Each pick-to-order item has a unique set of options that your user sets, making it impossible to stock these variations in inventory. So you can substitute a pick-to-order item for another pick-to-order item, but Order Promising won't consider the substitution when it calculates the promising dates.

- See what you can substitute in a shipment set. For details, see Ship Order Lines in Shipment Sets.

Unit of Measure

Make sure the original item and the item that you use to substitute the original have the same unit of measure. Order Management doesn't convert the unit of measure when it does the substitution.

Assume the unit of measure for the AS54888 is Each, but its Dozen for the AS55000. At run time, you submit the sales order, Order Management substitutes the AS55000 for the AS54888, but continues to display Each on the fulfillment line. Your warehouse won't be able to accurately do the substitution because the unit of measure isn't correct. Here's how to avoid this problem.

- Go to the Product Information Management work area, then click Tasks > Manage Items.

- Open the AS54888 for editing, then notice the value in the Primary Unit of Measure attribute.

- Open the AS55000 for editing, then make sure the Primary Unit of Measure attribute contains the same value that the AS54888 has for this attribute.

Set Up Your Item

Summary of the Setup

-

Set up your item.

-

Collect data.

-

Test your set up.

Assume you must set up substitution for the AS54888 Computer.

-

If the AS54888 Computer isn't available in inventory, then substitute it with the CN92777 Computer.

Try it.

-

Go to the Product Information Management work area.

-

On the Product Information Management page, click Tasks > Manage Items.

-

On the Manage Items page, search for your item.

Attribute

Value

Item

AS54888

-

In the Search results, in the Item column, click AS54888.

-

On the Edit Item page, click Relationships.

-

In the Relationships area, click Actions > Create, set the values, then click OK.

Attribute

Value

To Item

CN92777 Computer

Type

Substitute

Planning Enabled

Contains a check mark.

-

On the Edit Item page, click Save.

Collect Data

-

Go to the Plan Inputs work area, then click Tasks > Collect Planning Data.

-

In the Collect Planning Data dialog, set the values.

Attribute

Value

Source System

GPR

Collection Type

Targeted

-

Move the Item Substitution Relationships reference entity to the Selected Entities window, then click Submit.

-

In the Status dialog, notice the process number. For this example, assume its 50465.

-

Go to the Scheduled Processes work area.

-

Locate 50465 in the Process ID column. Monitor the process until the Status column displays Succeeded.

-

Refresh the Order Promising server.

-

Go to the Scheduled Processes work area, then click Action > Schedule New Process.

-

In the Schedule New Process dialog, set the value.

Attribute

Value

Name

-

Add a check mark to the Items parameter, then click Submit.

-

Click Actions > Refresh, then verify the status is Succeeded. Repeat, as necessary.

-

For details, see Collect Planning Data for Order Management.

Test Your Set Up

-

Go to the Order Management work area and create a new sales order.

-

Click Shipment Details > Supply, then set the value.

Attribute

Value

Allow Item Substitution

Yes

-

Search for the AS54888 on the catalog line, notice that the line displays Out of Stock, then click Add.

-

Notice that the order line contains the AS54888, then click Submit.

-

Click Actions > Switch to Fulfillment View.

-

Verify that Order Management replaced AS54888 with CN92777.