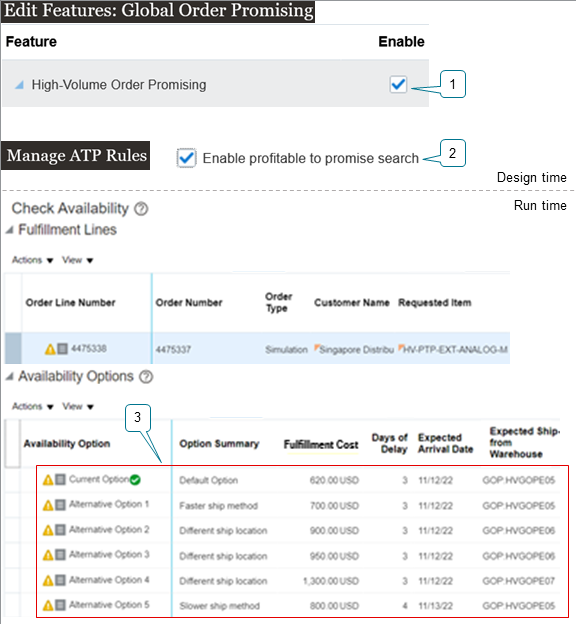

Create Alternative Fulfillment Scenarios to Reduce Cost

Set up Promising so you can select an alternative fulfillment scenario that has the lowest total cost to fulfill the item.

Maximize your profit margin. Use the option that costs the least in your profitable to promise flow. Reduce the cost that you incur for the item in your organization, the cost to transfer the item between organizations, and the transit cost that you incur to ship the item from your supplier.

Here's what you do.

- Enable the High Volume Order Promising feature. Promising will include the cost that you incur to ship the item from the ship from location to your customer's site when you schedule the arrival date. You can also include a manufactured item’s resource cost and material cost from a bill of resources.

- Enable profitable to promise on your ATP rule. Use it so you can change the source that you would normally use to fulfill the item to a source that's more cost effective.

- At run time, use the Check Availability action to examine the default

availability option that Promising is currently using and alternative options

that might be more cost effective, for example, by using a different shipping

method or by shipping from a different location. Use the default, or select an

alternative.

For example, select from one of these:

Availability Option Option Summary Fulfillment Cost Days of Delay Expected Arrival Date Expected Ship From Warehouse Current Option Default Option $620 3 1/1/2023 Denver Alternative Option 1 Faster Ship Method $700 3 1/1/2023 Denver Alternative Option 2 Different Ship Location $900 3 1/1/2023 Seattle Alternative Option 3 Different Ship Location $950 3 1/1/2023 Portland Alternative Option 4 Different Ship Location $1,300 3 1/1/2023 San Francisco Alternative Option 5 Slower Ship Method $800 4 1/2/2023 Denver

Notice how the action prioritizes on time delivery over cost. For example, option 5 costs less than options 2, 3, and 4, but option 5 is last in the list because it adds another day of delay.

Prioritize

Promising's number one objective is to fulfill the sales order on time or with minimum delay. If promising finds that there's more than one way to fulfill the order within the requested date, then it considers the cost for each source to help decide which source to use. For example, it considers inventory cost, transfer cost, and delivery cost. If you have to manufacture the item, then it also looks at the rolled up cost.

Here's how Promising prioritizes demand.

| Priority | Description | Sort Top Six Fulfillment Scenarios on Check Availability Page According To |

|---|---|---|

| 1. On Time Delivery | Promising gives the highest priority to fulfilling the sales order on time or with the minimum delay according to the requested date and the quantity. | Expected promise date |

| 2. Cost | Promising gives the next highest priority to fulfilling the sales order according to cost. | Cost |

Here are the costs that Promising considers.

| Cost | Description |

|---|---|

| The item's standard cost. |

If you have the item in stock, then Promising uses the standard cost of the item or the cost to substitute it. You must collect the item's cost. |

| Supplier cost at the supplier's location. | If you purchase the item, the Promising uses the supplier cost that you import through the Approved Supplier List file based data import (FBDI). |

|

Cost to transfer the item:

|

Promising uses the transfer cost for each unit that you specify in the Manage Transit Times task for each of these types of transfers. |

The bill of resources doesn't include cost for an item that you manufacture. Instead, Promising calculates it.

| Cost | Description |

|---|---|

|

Cost to build the item and its subassemblies.

|

Includes the resource cost for each critical resource in the bill of resources. If your item has more than one level, then Promising rolls up the resource costs. You must collect the resource cost. |

| Cost of the raw materials for the item's manufacturing components. |

Promising uses the standard cost of the item. If you must purchase the raw materials, then Promising uses the supplier's cost at the supplier location. |

| Cost to transport the raw material, manufacturing components, or subassemblies to your factory. | Promising uses the transfer cost for each unit that you specify in the Manage Transit Times task to determine the cost that you incur when you transport the item from your supplier to your organization or between organizations. |

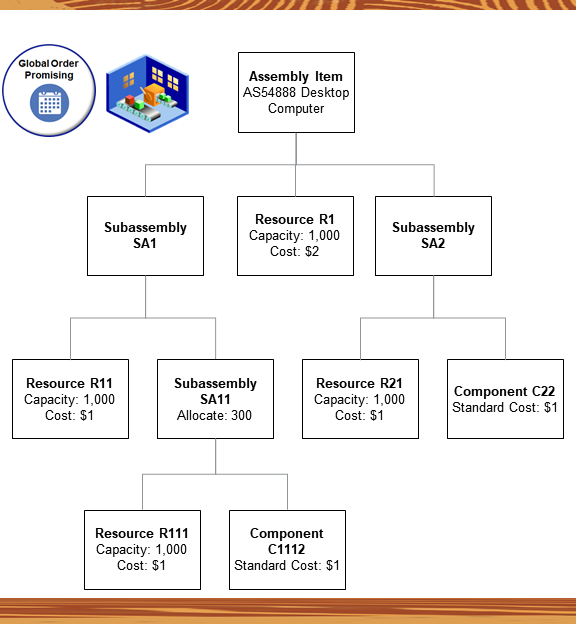

Example

Assume you have this supply chain network.

Assume

- You need to promise an order line for the AS54888 Desktop Computer item, with a quantity of 10.

- The AS54888 includes subassembly SA1 and subassembly SA2.

- You use the R1 resource to assemble SA1 and SA2.

- Capacity is for each day and cost is for each unit. For example, R1 can build 1,000 units each day at a cost of $2 for each unit.

- You make each subassembly from other subassemblies or manufacturing components, and you use different resources to assemble them.

- You build the subassemblies and the AS54888 in you factory.

- All manufacturing components and resources are available in the factory.

| Resource or Manufacturing Component | Cost for Each Unit | Quantity | Total |

|---|---|---|---|

| C22 | $1 | 10 | $10 |

| C1112 | $1 | 10 | $10 |

| R1 | $2 | 10 | $20 |

| R21 | $1 | 10 | $10 |

| R11 | $1 | 10 | $10 |

| R111 | $1 | 10 | $10 |

| - | - | Total Fulfillment Cost: | $70 |

Note

- Promising uses the critical manufacturing components and critical resources from the bill of resources.

- Promising looks at all possible paths through your supply chain, then gives you the least expensive path.

- Promising doesn't return the individual cost for any assembly or subassembly when you build the item. Instead, it returns the cost when it promises the AS54888 from your available to promise inventory after you finish building the item.

Promise According to Arrival Date

Promising considers the cost of shipping the item to your customer when you promise according to the arrival date. Assume you need to promise an order line for the AS54888 item with a quantity of 10. You have three different factories that can build the item, and the cost to build and ship each unit is different for each factory.

| Rank | Factory | ATP Supply | Transit Time | Cost to Build Each Unit | Cost to Ship Each Unit | Fulfillment Cost |

|---|---|---|---|---|---|---|

| 1 | Denver | 10 | 2 days | $1 | $1.30 | $23.00 |

| 2 | Seattle | 30 | 2 days | $2 | $0.25 | $22.50 |

| 3 | San Francisco | 30 | 3 days | $5 | $1.50 | $65.00 |

Denver has the highest rank, but Promising will fulfill the item from Seattle because Seattle can promise the item in the same amount of time that Denver can, but Seattle has the lowest cost. Here's the math for the fulfillment cost.

| Factory | Cost to Build Each Unit | Cost to Ship Each Unit | Quantity | Fulfillment Cost | Math |

|---|---|---|---|---|---|

| Denver | $1 | $1.30 | 10 | $23.00 | $1 plus 1.30 multiplied by 10 |

| Seattle | $2 | $0.25 | 10 | $22.50 | 2 plus 0.25 multiplied by 10 |

| San Francisco | $5 | $1.50 | 10 | $65.00. | 5 plus 1.50 multiplied by 10 |

The same logic applies when you transfer supply from a supplier except Promising looks at the cost to transfer each unit instead of the cost to build each unit.

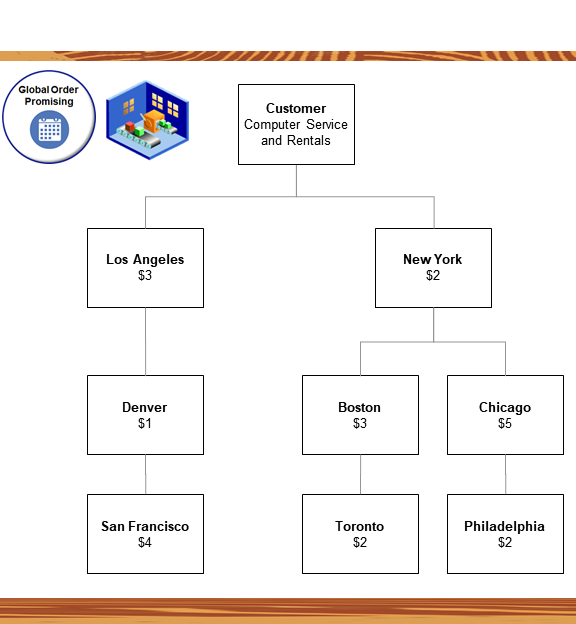

How Promising Examines Your Supply Chain Network

Example 1

Note

- You need to promise an order line that has a quantity of 20.

- The requested arrival date on the line is the system date.

- A quantity of 10 units are available on the requested arrival date at every organization in your network.

- You can split the line across factories but you must deliver the entire quantity together in a single shipment.

Promising will look at every node in your network until it has fulfilled the requested quantity.

| Result | Supply Chain Path | Fulfillment Cost | Math |

|---|---|---|---|

| Default | Los Angeles first, and then Denver | $40 |

|

| Alternative 1 | New York first, and then Boston | $50 |

|

Note

- Promising will start with the default path, which is Los Angeles.

- If the Los Angeles path can't meet demand, then Promising will look at the New York path.

- The Los Angeles path costs less, so Promising will promise from Los Angeles.

Example 2

Assume the same scenario except with a quantity of 30.

| Result | Supply Chain Path | Fulfillment Cost | Math |

|---|---|---|---|

| Default | New York first, then Boston, then Toronto | $70 |

|

| Alternative 1 | Los Angeles first, then Denver, then San Francisco | $80 |

|

| Alternative 2 | New York first, then Chicago, then Philadelphia | $90 |

|

Note

- Promising will start with New York as the default path.

- If the New York path can't meet demand, then Promising will look at Boston because Boston is more cost effective than going through Philadelphia.

- If Boston can't meet demand, then Promising will look at the Los Angeles path because going through Los Angeles is more cost effective than going through Philadelphia.

Guidelines

- The bill of resources doesn't include the cost to manufacture the item. Instead, promising calculates that cost when it promises the item according to the item cost, transfer cost, and so on.

- Promising considers transfer cost for a manufactured item according to your sourcing rule. It won't consider the cost that you incur to transfer the item between organizations in your bill of resources. If you want Promising to apply a transfer cost, then you must specify that the item is critical at the source and at the destination in your bill of resources.

- Make sure you set up costs correctly in your Oracle Applications, such as your transfer cost, standard item cost, supplier cost, resource cost, and so on.

Try It

- Set up your ATP rule.

- Go to the Global Order Promising work area.

- Click Tasks > Manage ATP Rules.

- Create a new rule or open one that you already have for editing, then

set the attributes.

Attribute Value Enable Profitable to Promise Search Contains a check mark.

You must enable this attribute.

Promising will assume this option is enabled for all organizations in your supply chain network, and will use this feature for all of those organizations.

- If you drop ship your item, then:

- Set the attribute.

Attribute Value Promising Mode Supply Chain Availability Search - Click ATP Rule Assignment, then set the

attribute.

Attribute Value Assigned to Organization Set this attribute to your drop ship validation organization.

- Set the attribute.

- At run time, use the Check Availability action to examine your availability options. Use the default, or select an alternative.