Get Promising Dates in Real Time

Get accurate available-to-promise dates from across millions of possible fulfillment scenarios.

Use this feature to get the supply that's currently on hand or in transit from Inventory Management, Manufacturing, and Shipping without having to collect data. This reduces the amount of data processing that Promising must do and reduces the time Promising needs to collect supply data. Promising can then optimize fulfillment for your item from millions of different possible scenarios according to where the item does or could reside in your supply chain at any given moment.

Use this feature when your supply is fragmented across warehouses and distribution centers.

- Get supply updates in real time, updated every second.

- Schedule sales orders for thousands or even millions of items across hundreds of organizations.

- Remove the latency that happens when you have to collect supply and demand data for your items, then synchronize that data with your transaction system.

- Improve promising accuracy. You can consider supply that's on hand and in transit, in real time, across your item’s supply chain.

Use this feature when you need to create new supply through capable-to-promise rules, when inventory isn't available, when you don't want to procure or build new supply to fulfill customer demand, and you want Promising to only consider supply that's on hand or in transit.

How it Works

Promising uses your global and local sourcing rules to determine supply sources, and it does it in two phases to promise each new sales order.

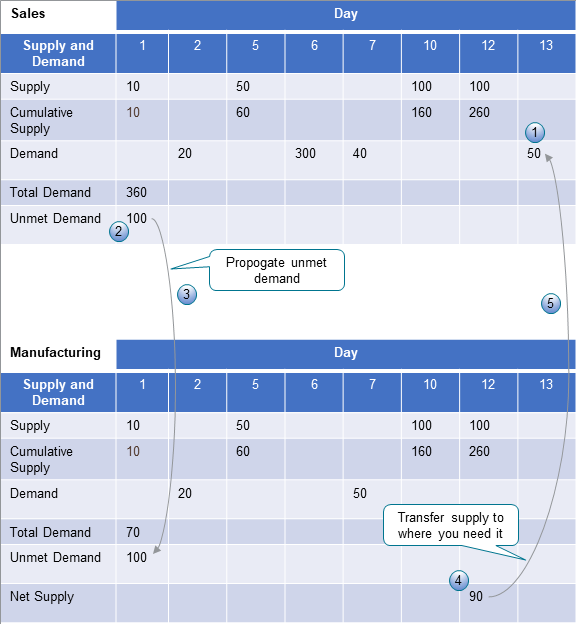

Assume you have two organizations. The Sales organization is upstream of the Manufacturing organization in your supply chain. Here's what Promising does:

- Nets demand and supply against each other in Sales to determine what supply is available in Sales.

- Examines your supply chain network from Sales to Manufacturing, adds unmet demand to the demand that currently exists in Manufacturing, then nets demand against whatever supply currently exists in Manufacturing. If Sales has more supply than it needs to meet its own demand, then Promising moves on to the second phase,

- Calculates the supply that's available for Sales before it calculates it for Manufacturing.

- Promises the new sales order according to the supply that's available, lead times, calendars, and so on.

Assume you sell the AS54888 desktop item, and you keep supply for it in Sales and in Manufacturing. The supply for Sales and Manufacturing is:

- 10 units on day 1

- 50 units on day 5

- 100 units on Day 10

- 100 units on day 12

So, Sales and Manufacturing each have a total supply of 260 units.

What the Numbers Mean

- You receive new demand of 50 units on day 13 for the item in Sales.

- Assume Promising already promised some supply to fulfill previous sales orders for 20 units, 300 units, and 40 units, for a total demand quantity of 360 units. So, the total quantity of unmet demand in Sales is 100 units (360 minus 260).

- Promising propagates the unmet demand to Manufacturing, according to how you set up your sourcing rules. For this example, assume it propagates all of 100 from Sales to Manufacturing.

- The incoming supply for Manufacturing is 260 units, with demand in Manufacturing of 70 units. The total demand including unmet demand that Promising propagates from Sales to Manufacturing is 170 units. So, the net supply that Promising can use to promise new sales orders on day 12 in Manufacturing is 90 units (260 minus 170).

- Promising transfers the supply quantity that it needs to promise the item from Manufacturing to Sales.

Guidelines for Collecting

- You must collect your setups.

- If you need to check availability or schedule a capable-to-promise or profitable-to-promise request, then you must collect data even if you use this feature.

- If you use source promising, then you don't need to collect the Items, On-Hand, Transfer Orders, Sales Orders, or Reservations entities.

- You can collect any other entities that you need to promise orders when you don't use this feature, such as Customers, Calendars, Regions, Organizations, and so on.

Source Promising

If you use source promising in a flow that isn't a back-to-back flow, then this feature will also consider supplies that have an availability date that happens in the future, such as supply that you might get through a purchase order, transfer order, or work order where supply doesn't exist until you actually purchase it, transfer it, or build it. This helps you to provide your customers with accurate availability dates for items where you don’t currently have any stock. Do this instead of putting the item on backorder. For background details, see Source Promising.

Notes

- Promising will consume all the supply that's currently available in your supply chain for the item.

- You must use source promising with any sourcing or available-to-promise rules that you plan to use with this feature.

- This feature does consider any inventory reservations that exist for supply.

- This feature doesn't consider the available-to-promise fence. It does consider the infinite fence when it nets the backlog for future sales orders. It considers the order quantity regardless of whether you use the infinite fence to promise the order. For details, see Time Fence.

- If you use source promising, and if your flow isn't a back-to-back flow, then Promising doesn't source supply for your make rules or buy rules.

Limitations

You can use this feature only for sales orders that you get from Oracle Order Management. You can't use it with any other ordering system.

Set it Up

- Make sure you have the privileges that you need to administer Oracle Global Order Promising.

- Enable the MSP_ENABLE_GOP_WITH_NEW_ARCH profile.. See Manage Promising Profiles.

- Set up your item.

- Go to the Product Information Management work area.

- Click Tasks > Manage Items.

- Search for, then open your item for editing.

- Click Specifications > Sales and Order

Management, then set the value.

Attribute Value Check ATP Source Based Promising

Use Categories to Simplify Your Setup

Assign each of your sourcing rules and available-to-promise rules to a category and reduce the amount of setup you need to do.

You can use a category to group items according to your sourcing requirements, supply and demand requirements, or any other business need. For example, group items that don't have a lot of demand and that you store in regional and national distribution centers, that you fulfill from the regional level first and then from the national level, and that have an infinite fence of 100 days.

Here is a generic procedure that you can do when you want to use a category with this feature:

- Create your category inside the catalog and include your items in each

category.

- Control the catalog at the master level.

- Don't includes hierarchies of categories in the catalog.

- Make sure that the Allow Multiple Item Category Assignments option doesn't contain a check mark.

- Add your items to the categories.

- Add items only to levels that are lower in the categories.

- Assign the catalog to the Planning functional area.

- Make sure you don't have more than one assignment for each item category. For details about catalogs and categories, including how to create a catalog and add categories and items to it, see How Catalogs Work Together.

- Collect the catalog and the category.

- Go to the Planning Central work area, click Tasks > Manage Planning

Profile Options, set the values, then click

Search.

Attribute Value Profile Option Code MSC_SRC_ASSIGNMENT_CATALOG Category Global Order Promising - In the Profile Values area, set the Profile Value attribute to your catalog.

- Set up your available-to-promise rules and sourcing rules and assign them to your categories.

Guidelines for Assignment Levels

Here are the levels that you can and can't use.

| Rule | Support |

|---|---|

| Global Sourcing Rule |

You can use these levels:

You can't use these levels:

|

| Local Sourcing Rule |

You can use these levels:

You can't use the Item and Organization level. |

| ATP Rule |

You can use these levels:

You can't use these levels:

|

For details, see Set Your Assignment Levels.