Overview of Global Order Promising

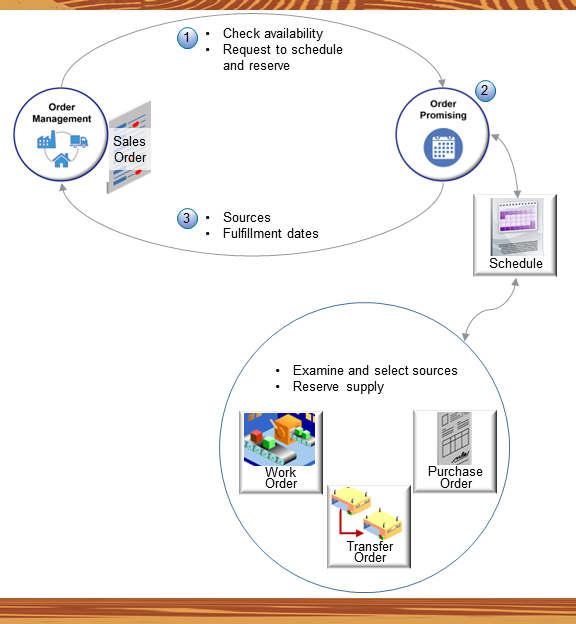

Oracle Global Order Promising is an application that helps you fulfill sales orders by the requested date for items that you receive from your ordering application, such as Oracle Order Management.

Promising considers the supply that is or might be available in your entire supply chain, including suppliers, factories, distribution centers, and warehouses.

Assume you sell an item named the AS54888 Desktop Computer. You place a sales order in Order Management for the AS54888 with a requested delivery date of March 10.

- Order Management sends a request that includes these details to Promising. The request might be to check and see whether the item is available, or to schedule and reserve the item for fulfillment.

- Promising uses its schedule to look at a variety of sources that can fulfill

demand within the date that Order Management requested, depending on how you set

it up. For example, it can try to get supply from:

- Work orders that create supply for the item in manufacturing

- Transfer orders that transfer supply between organizations when that supply already exists

- Purchase orders that purchase supply for the item from a supplier

- Promising sends supply details to Order Management, including the source that will supply the item, fulfillment dates, and so on.

Promising can do this in different ways, depending on how you set it up:

- Select from a variety of fulfillment locations.

- Use an available-to-promise rule that you create to consume on-hand supply that already exists in your supply chain, inventory that's in transit, or to get supply through a purchase order, transfer order, or through a planned order that Promising receives from Supply Planning.

- Use a capable-to-promise rule that you create to build supply that doesn't already exist in your supply chain. Capable-to-promise is the capacity to build inventory that isn't currently available in your supply chain.

- Substitute the ordered item with another item.

- If there isn't enough supply to fulfill the item from a single location, then Promising can split the order line according to location, time, substitution.

Make Your Supply Chain Flexible and Resilient

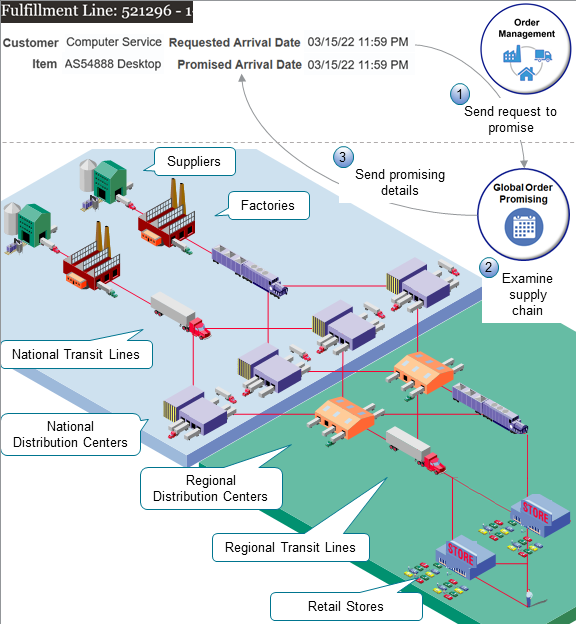

Consider this example of a supply chain.

Here's how it works.

- Order Management sends a request to Promising to promise an item, such as the AS54888 Computer, according to the requested arrival date.

- Promising uses the set ups that you make in the Global Order Promising work area to examine the supply chain and promise the item so it arrives at your customer's site by the requested arrival date.

- Promising sends promising details to Order Management, such as the Promised Arrival Date.

Assume your supply chain has:

- Supplier A and Supplier B

- Factory A and Factory B

- National Distribution Center 1

- National Distribution Center 2

- National Distribution Center 3

- National Distribution Center 4

- Regional Distribution Center 1

- Regional Distribution Center 2

- Retail Store 1

- Retail Store 2

- Retail Store 3

- Retail Store 4

- Truck Transit

- Rail Transit

You can set up Promising so it considers a variety of alternatives in this chain. Here are just a few examples:

- Use Supplier A, Factory A, National Distribution Center 2, Regional Distribution Center 1, and Truck Transit only for high priority orders.

- Use Supplier B, Factory B, National Distribution Centers 1, 3 and 4, Regional Distribution Center 2, and Rail Transit only for low priority orders.

- Use Supplier B only if Supplier A can't fulfill the item.

- Use only Factory B to build the AS54888 item. Don't use Factory A to build it. If Factory B can't build it in time to meet the requested fulfillment date, the get it from Supplier A.

- Allocate 60% of your supply to your high priority customers, and 40% of it to lower priority customers.

- Use Factory A and Factory B in January, but use only Factory B in February.

Principles of Promising

Promising applies a set of principles to prioritize your sources of supply.

Principle 1: Meet Demand on Time

Promising’s highest priority is to find sources that meet your customer’s requested date. If it can't, then it fulfills to the next available date. You can use the Check Availability feature to reexamine the sourcing that Promising selects. You can also use it to test a variety of different what-if scenarios. For details, see Check Availability.

Principle 2: Consume Supply That Already Exists Before Creating New Supply

Promising uses whatever supply that's currently available first. If there isn't enough, then Promising uses capable-to-promise to consume materials, resources, or suppliers to make, buy, or transfer the goods it needs to meet demand.

You can use the ATP Time Fence feature to modify this behavior. If the requested date happens after the fence, then Promising consumes capable-to-promise supply and resources before it looks at supply that already exists. For details, see Time Fence.

Principle 3: Use the Source That Has the Lowest Cost

Promising can prioritize the location and transit mode that has the lowest cost while still meeting the requested date. If you use profitable-to-promise, then Promising also considers the cost of manufacturing components and resources.

You can specify whether to use profitable-to-promise on your available-to-promise rule. For details, see Set Attributes on Your Supply Chain Search.

Principle 4: Source According to the Location's Priority

If you source from more than one location, then you can set up Promising so it selects the location according to a priority that you set on your sourcing rule, such as customer, zone, category, item, or demand class. For details, see Set Your Assignment Levels.

Principle 5: Use a Similar Item to Substitute Your Item

Promising can substitute one ordered item for another. For example, if the item is the AS54888 desktop computer, then it can substitute the AS54888 for the AS6000 desktop computer. If another location has enough supply to meet demand, then Promising consumes supply from that location to fulfill the order and won't substitute, by default. You can also use the Order Management work area to control substitution. For details, see Split or Substitute Fulfillment Lines.

Principle 6: Split Order Lines to Prevent Delay

Promising can split an order line into two lines to meet the requested date. Promising splits the line across the primary item and a substitute item. If no split meets the date, then Promising can split across time, delivering part of the quantity on time or with minimal delay, and the rest later. You can also use the Order Management work area to control splitting. For details, see Split or Substitute Fulfillment Lines.

Principle 7: Use Supply Just In Time

Promising consumes supply on the latest possible date while still meeting demand. This principle preserves supply that's available earlier for sales orders that have an earlier requested date, including sales orders that have an earlier requested date but that you haven't created yet.

You can set up your available-to-promise rule to control which types of supply Promising considers. For example, if through experience you find that the expected receipt date isn't reliable for a category of items on your purchase orders, then you can exclude them, and rely only on supply that's on hand or in transit.

Examples

Assume today is March 5th, you receive an order for 1,000 desktop computers from your Computer Service and Rentals customer, with requested delivery date of March 10. Assume you source from two factories in your supply chain.| Supply | Quantity in Shanghai | Quantity in Hong Kong |

|---|---|---|

| Currently on hand | 200 | 100 |

| In transit that you expect to receive on March 6 | 200 | 100 |

| On order from your contract manufacturer that you expect to receive on March 7 | 200 | 100 |

| Planned units that you expect to build on March 8 but haven’t released to production. | 200 | 100 |

| Daily Production capacity starting on March 9 | 200 | 500 |

| Promise | 5-Mar | 6-Mar | 7-Mar | 8-Mar | 9-Mar | 10-Mar |

|---|---|---|---|---|---|---|

| Shanghai, Available to Promise | 200 | 200 | 200 | 200 | - | - |

| Shanghai, Capable to Promise | - | - | - | - | 200 | 200 |

| Hong Kong, Available to Promise | 100 | 100 | 100 | 100 | - | - |

| Hong Kong, Capable to Promise | - | - | - | - | 500 | 500 |

If you don’t limit the supply that Promising can consider, then it consumes the available-to-promise supply from the bold cells in Shanghai first, and then begins to consume the capable-to-promise supply to meet demand just in time.

| Promise | 5-Mar | 6-Mar | 7-Mar | 8-Mar | 9-Mar | 10-Mar |

|---|---|---|---|---|---|---|

| Shanghai, Available to Promise | 200 | 200 | 200 | 200 | - | - |

| Shanghai, Capable to Promise | - | - | - | - | 200 | 200 |

| Hong Kong, Available to Promise | 100 | 100 | 100 | 100 | - | - |

| Hong Kong, Capable to Promise | - | - | - | - | 500 | 500 |

If you set the time fence to 3 days, then Promising uses the bold capable-to-promise supply first, and then the bold available-to-promise supply. This approach keeps the 200 units of available-to-promise supply on March 5th in Shanghai available for other sales orders that have an earlier requested date.

| Promise | 5-Mar | 6-Mar | 7-Mar | 8-Mar | 9-Mar | 10-Mar |

|---|---|---|---|---|---|---|

| Shanghai, Available to Promise | 200 | 200 | 200 | 200 | - | - |

| Shanghai, Capable to Promise | - | - | - | - | 200 | 200 |

| Hong Kong, Available to Promise | 100 | 100 | 100 | 100 | - | - |

| Hong Kong, Capable to Promise | - | - | - | - | 500 | 500 |

If you enable the profitable-to-promise option, and if the transit cost to deliver your item from Hong Kong is less than it is from Shanghai, and if the item costs are the same, then Promising sources all the supply it needs from the bold capable-to-promise supply in Hong Kong.

| Promise | 5-Mar | 6-Mar | 7-Mar | 8-Mar | 9-Mar | 10-Mar |

|---|---|---|---|---|---|---|

| Shanghai, Available to Promise | 200 | 200 | 200 | 200 | - | - |

| Shanghai, Capable to Promise | - | - | - | - | 200 | 200 |

| Hong Kong, Available to Promise | 100 | 100 | 100 | 100 | - | - |

| Hong Kong, Capable to Promise | - | - | - | - | 500 | 500 |

What if your customer places the order with only a three-day lead time, March 8, instead of five days, March 10? If you enable splitting, then Promising uses all the bold supply that's available in Shanghai, and the rest from Hong Kong.

| Promise | 5-Mar | 6-Mar | 7-Mar | 8-Mar | 9-Mar | 10-Mar |

|---|---|---|---|---|---|---|

| Shanghai, Available to Promise | 200 | 200 | 200 | 200 | - | - |

| Shanghai, Capable to Promise | - | - | - | - | 200 | 200 |

| Hong Kong, Available to Promise | 100 | 100 | 100 | 100 | - | - |

| Hong Kong, Capable to Promise | - | - | - | - | 500 | 500 |

| Promise | 5-Mar | 6-Mar | 7-Mar | 8-Mar | 9-Mar | 10-Mar |

|---|---|---|---|---|---|---|

| Shanghai, Available to Promise | 200 | 200 | 200 | 200 | - | - |

| Shanghai, Capable to Promise | - | - | - | - | 200 | 200 |

| Hong Kong, Available to Promise | 100 | 100 | 100 | 100 | - | - |

| Hong Kong, Capable to Promise | - | - | - | - | 500 | 500 |