Safety Stock Planning Methods

You can select a Safety Stock Planning Method to plan safety stock for your plan.

Use the Supply Planning, Planning Central, or Demand and Supply work area to open the Plan Options page, Safety Stock tab, where you can select the safety stock planning method.

The following are the four safety stock planning methods from which to select:

-

Do not plan safety stock

-

User-specified values for all items

-

Statistical safety stock for end items, none for all others

-

Statistical for end items, user-specified for all others

-

If the Apply the override quantities for safety stock check box is selected for the plan.

-

If a planned item has its safety stock override item attribute set to Not Null.

Do Not Plan Safety Stock

Select this method if you don't want safety stock calculated or planned for any item in the plan.

If you select this method, the Parameters for Safety Stock Calculation and Parameters for Safety Stock Smoothing sections aren't available.

User-Specified Values for All Items

Select this method to plan safety stock for all items based on the safety stock method for each item. In this case, safety stock planning doesn't consider statistical safety stock parameters. With this option the planning process calculates safety stock in one or more of the following ways:

-

If the Safety Stock Planning Method item attribute is set to Non-MRP Planned, then you can upload safety stock quantities by using CSV files for those items.

-

If the Safety Stock Planning Method item attribute is set to Days of cover, then the planning process calculates safety stock based on the user-specified days of cover for those items.

-

If the Safety Stock Planning Method item attribute is blank, the planning process doesn't plan safety stock.

If you select this method, the Parameters for Safety Stock Smoothing section is editable. However, the Parameters for Safety Stock Calculation section isn't available.

Statistical Safety Stock for End Items, None for All Others

Select this method to plan safety stock only for the end items that have statistical safety stock parameters defined for them. The planning process doesn't plan safety stock for items that don't have forecasts defined.

If you select this method, the Parameters for Safety Stock Calculation and Parameters for Safety Stock Smoothing sections are editable. Statistical safety stock is calculated with parameters specified at the item, policy, or measure level.

Statistical for End Items, User-Specified for All Others

Select this method to calculate and plan statistical safety stock for end items and user-specified safety stock for all other items.

If you select this method, the Parameters for Safety Stock Calculation and Parameters for Safety Stock Smoothing sections are editable. Statistical safety stock is calculated with parameters specified at the item, policy, or measure level.

Safety Stock Planning Logic

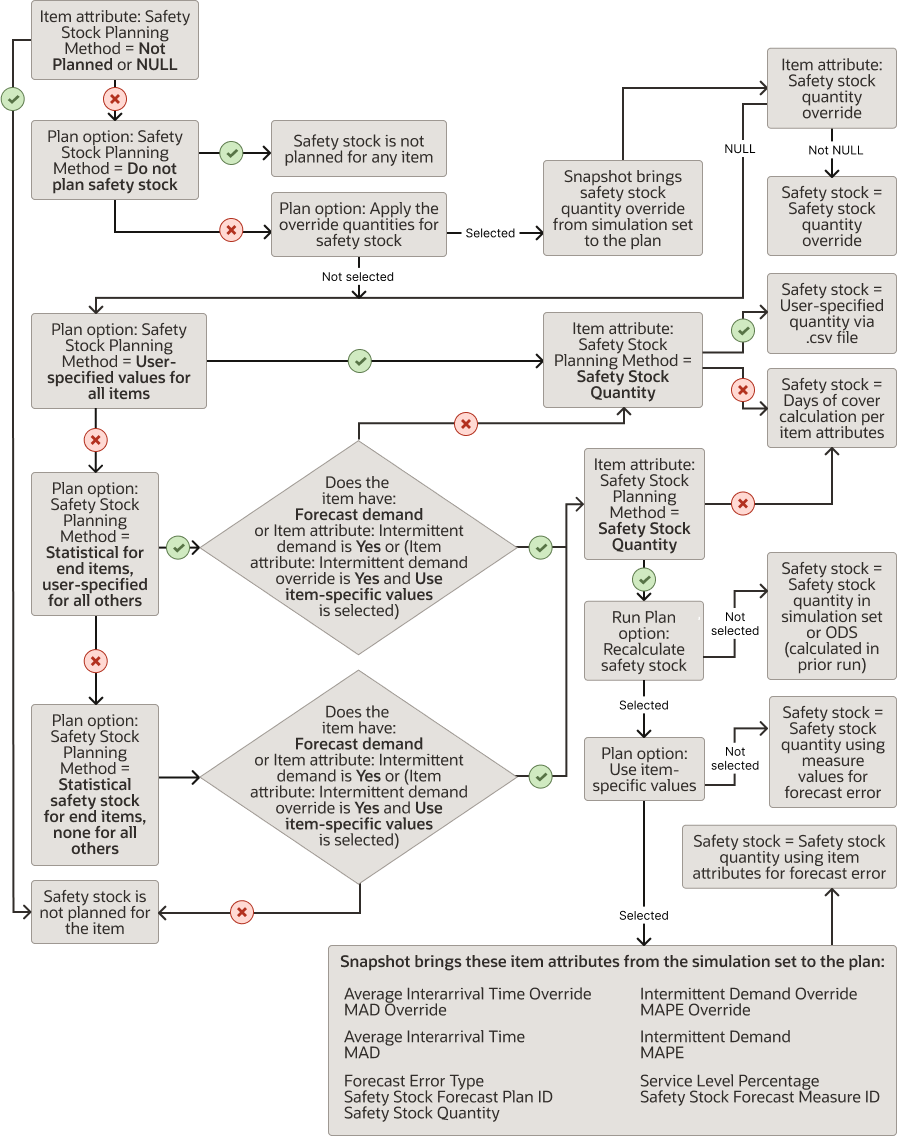

The following flowchart describes the logic used by supply planning to determine the safety stock method for an item.