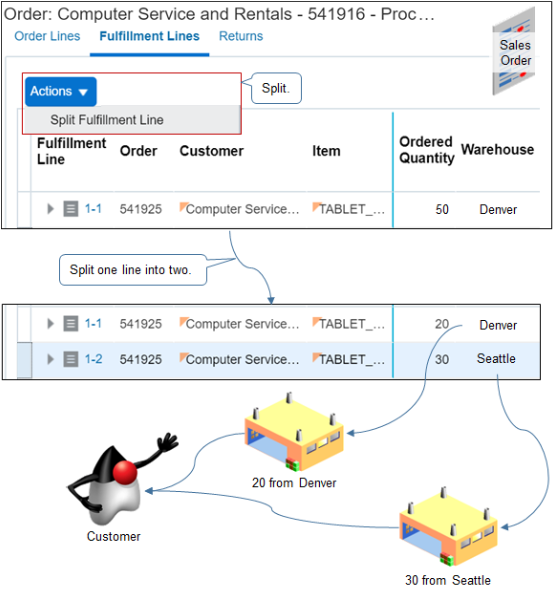

Fulfillment Line Splits

Split a fulfillment line into more than one fulfillment line to improve order fulfillment performance.

Splitting a fulfillment line is a supply chain technique you can use to fulfill your sales order in a timely and efficient way. For example, assume a fulfillment line includes a quantity of 50 for the TABLET item, but the preferred warehouse, the Denver warehouse, only has a quantity of 30 in stock. The Seattle warehouse has 40. To avoid a delay, you can split the fulfillment line so it gets the quantity it needs from Denver and Seattle.

There are different types of splits.

|

Type of Split |

Description |

|---|---|

|

Manual |

Note

|

|

Automatic |

Note

|

Sometimes Order Management doesn't allow a split.

-

The Splits Allowed attribute on the fulfillment line doesn't allow the split.

-

The fulfillment line doesn't allow a split. If you use an override privilege, then you can override this restriction.

-

The quantity of the fulfillment line is one or less.

-

The fulfillment line is in a shipment set. To split this line, remove it from the shipment set, then split it.

How Order Management Determines Availability

A substitution is the act of replacing one item with some other item. For example, replacing an 80GB hard drive with a 100GB hard drive because there aren't any 80GB hard drives in inventory.

Here are the substitutions that Order Management considers to determine availability when it splits a fulfillment line.

|

Where Split Happens |

Description |

|---|---|

|

Split a fulfillment line across more than one warehouse. |

If the Requested Ship-from Warehouse attribute on the fulfillment line is.

Each fulfillment line that the split creates might specify a different value for the Expected Ship-from Warehouse attribute. Order Management uses business rules that your order administrator sets up to determine the warehouses it uses to supply the item. |

|

Split a fulfillment line across substitute items. |

Order Management substitutes an item only if the Allow Substitutions attribute on the fulfillment line equals Yes. Each fulfillment line that the split creates might specify a different value for the Available Item attribute. Assume you create a fulfillment line that requests 100 units of an item. Supply for the item is 80 units and supply for the substitute item is 50 units. Check Availability will split the fulfillment line into these fulfillment lines.

|

|

Split a fulfillment line across dates. |

If a fulfillment line requests inventory that isn't sufficient on a given date, then Order Management splits the line across dates.

Assume you create a fulfillment line on November 15, 2019 that requests 100 units of an item, and that supply is available for the item on these dates.

Check Availability will split the fulfillment line into these fulfillment lines.

|

How Split Fulfillment Lines Affect Status

Order Management creates two or more instances of the same fulfillment task when it splits a fulfillment line. These tasks might include different statuses during processing.

Consider some examples.

-

The status of the Schedule task for fulfillment line A1 is Not Scheduled, and the status of the Schedule task for fulfillment line A2 is Scheduled.

Order Management examines the split priority of the task statuses, then sets the orchestration process status to the task status that includes the highest split priority.

-

Order Management splits a fulfillment line that results in two instances of the Schedule task. One of these tasks includes a Complete status, and the other task includes a Pending status. The value of the split priority for Pending is two, and the value of the split priority for Complete is three.

Order Management sets the orchestration process status to Pending.