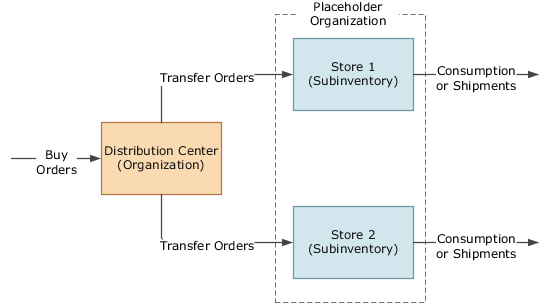

Example of Replenishment Plans for Stores Modeled as Subinventories

This topic describes how you set up replenishment plans for stores that are modeled as subinventories.

In this example, an enterprise has a distribution center that's modeled as an organization. The distribution center has buy from sourcing rules. The two stores, which are set up as subinventories and contained in a placeholder organization, source goods from the distribution center using transfer from sourcing rules. The customer demands are fulfilled through the stores. The enterprise owns the stores and uses Oracle Fusion Cloud ERP.

Note these points about this example:

- You can use a single replenishment plan to generate the forecast, calculate the

policy parameters, and calculate and release replenishment orders for the

distribution center and stores.

You can also use separate replenishment plans as follows:

- A replenishment plan generates the forecast at the distribution center

by using transfer orders history and shipments history.

This replenishment plan also calculates the policy parameters and calculates and releases the replenishment orders for the distribution center.

- Another replenishment plan generates the forecast at the stores by using

consumption or shipments history.

This replenishment plan also calculates the policy parameters and calculates and releases the replenishment orders for the stores.

- A replenishment plan generates the forecast at the distribution center

by using transfer orders history and shipments history.

- If you're using a single replenishment plan for the distribution center and

stores, when a planned transfer order is created at the stores, an equivalent

planned transfer order demand isn't automatically created for the distribution

center.

Planned transfer order demand is created at the distribution center once the planned transfer orders created at the stores are released and collected.

- File-based data import (FBDI) templates can be used for uploading data instead of collecting it.

- At the distribution center and store levels, you can use a single or separate replenishment plans to generate the forecast, calculate the policy parameters, and calculate and release the replenishment orders.