Scheduling of Replenishment Orders

This topic explains how buy and transfer replenishment orders are scheduled.

Scheduling of Buy Orders

Buy orders are forward scheduled from the suggested order date.

These points govern the scheduling of buy orders:

-

All valid shipping, organization receiving, supplier, transit, and manufacturing calendars are considered.

-

The processing lead time defined at the supplier level is first considered. Otherwise, the processing lead time defined in the Items table is considered. The preprocessing and postprocessing lead times defined in the Items table are also considered.

-

The preprocessing and postprocessing lead times are calculated according to the manufacturing calendar.

-

The transit time is calculated according to the transit calendar.

-

The processing lead time is calculated according to the supplier calendar.

-

Supplier capacity isn't considered.

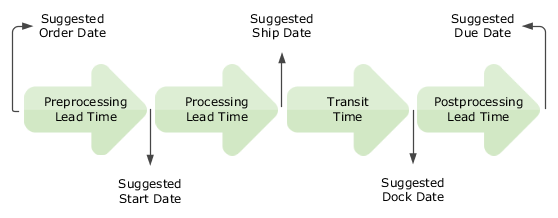

This figure depicts how various dates are determined for a buy replenishment order. The preprocessing lead time is added to the suggested order date for calculation of the suggested start date. The processing lead time is added to the suggested start date for calculation of the suggested ship date. The transit time is added to the suggested ship date for calculation of the suggested dock date. The postprocessing lead time is added to the suggested dock date for calculation of the suggested due date.

The suggested order date takes the manufacturing calendar into account, suggested start date takes the supplier calendar into account, suggested ship date takes the supplier shipping calendar into account, suggested dock date takes the organization receiving calendar into account, and suggested due date takes the manufacturing calendar into account.

For example, if Saturday and Sunday aren't working days, the suggested dock date is Friday, and the postprocessing lead time is 1 day, the suggested due date is Monday.

Scheduling of Transfer Orders

Transfer orders are forward scheduled from the suggested order date.

These points govern the scheduling of transfer orders:

-

All valid shipping, receiving, transit, and manufacturing calendars are considered.

-

The preprocessing lead time defined at the source organization is considered.

-

No processing lead time is considered.

-

The transit time is taken from the shipping method specified in the sourcing rule.

-

The postprocessing lead time defined at the destination organization is considered.

-

The preprocessing and postprocessing lead times are calculated according to the manufacturing calendars of the source organization and destination organization respectively.

-

The transit time is calculated according to the transit calendar.

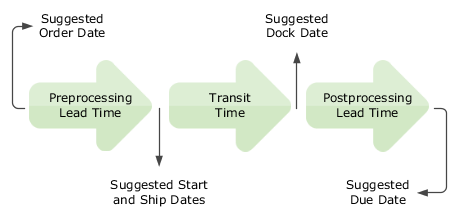

This figure depicts how various dates are determined for a transfer replenishment order. The preprocessing lead time is added to the suggested order date for calculation of the suggested start and suggested ship dates. The transit time is added to the suggested start and ship dates for calculation of the suggested dock date. The postprocessing lead time is added to the suggested dock date for calculation of the suggested due date.

The suggested order date and suggested start date take the source organization's manufacturing calendar into account, suggested ship date takes the source organization's shipping calendar into account, suggested dock date takes the destination organization's receiving calendar into account, and suggested due date takes the destination organization's manufacturing calendar into account. The suggested start date and suggested ship date are the same.

For example, if Saturday and Sunday aren't working days, the suggested dock date is Friday, and the postprocessing lead time is 1 day, the suggested due date is Monday.