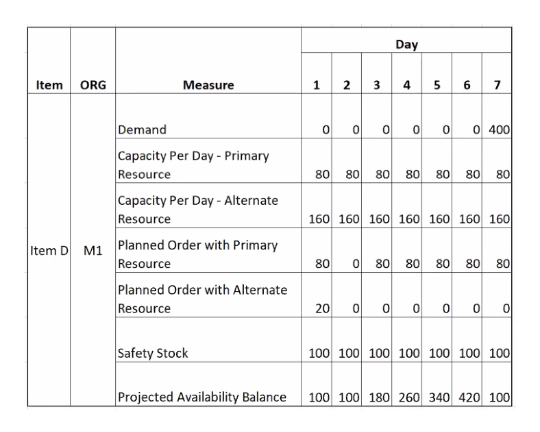

Example of Safety Stock Planning with Primary and Alternate Resources

This example shows how the supply planning process plans safety stock in a constrained supply plan that uses primary and alternate resources.

Safety Stock Planning with Primary and Alternate Resources

For this example, let's use these parameters:

-

Item D has a demand on Day 7

-

Item D has safety stock of 100 units from Day 1 to Day 7

-

Primary resource capacity per day is 80 units

-

Alternate resource capacity per day is 160 units

In this scenario,

-

To meet the safety stock quantity of 100 units, the planning process created supply for 80 units on the primary resource and 20 units on the alternate resource on Day 1.

-

The safety stock quantity of 100 units on Day 1 is satisfied because the plan creates supplies on the primary and alternate resource without violating the capacity constraint.