Overview of Back-to-Back Fulfillment

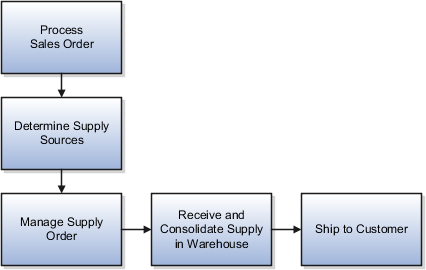

The back-to-back fulfillment process is one in which specific sales order demand triggers supply creation, and a link is established between the sales order and the supply.

Back-to-back flow is currently supported only for discrete manufacturing.

Back-to-back fulfillment is where supply is procured and then received at a warehouse only after an order is placed. The supply is reserved against a sales order until shipping. This process provides support to create and link supply after a sales order is entered and scheduled, allowing you to reduce your inventory while maintaining the ability to respond to customer demands.

You create supply for a back-to-back order using one or more of the following back-to-back flows:

-

Buy: Procurement from an external supplier.

-

Make: Production in an internal manufacturing facility (includes in-house manufacturing and contract manufacturing).

-

Transfer: Transfer from another warehouse.

-

On hand: Reservation of on-hand supply in the fulfillment organization.

For information about back-to-back flows for contract manufacturing, see the Implementing Contract Manufacturing chapter in this guide.

After the supply is received into the fulfillment warehouse, the back-to-back order is ready for shipment to the customer.