Guidelines for Reserving Inventory

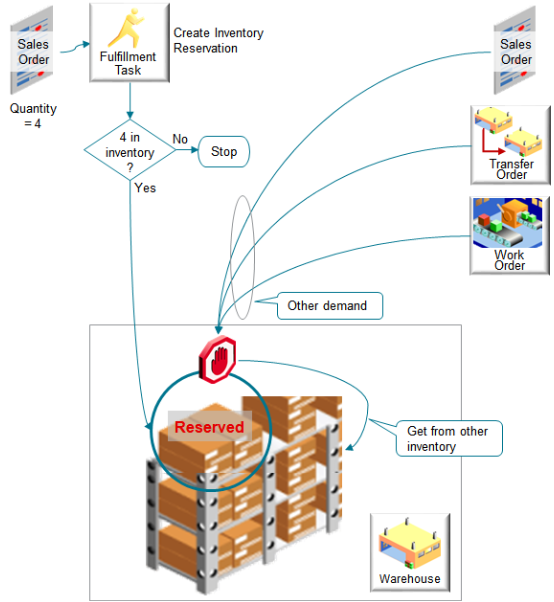

Reserve inventory to make sure its available for your sales order when its time to pick your item in the warehouse.

Reserve supply for a sales order so no other demand can use the supply. Demand includes other fulfillment lines in your sales order, fulfillment lines in other sales orders, transfer orders, work orders, and so on.

You use the Create Inventory Reservations fulfillment task to reserve supply. Here's what it does.

-

Uses your inventory system to reserve physical supply that currently exists in the warehouse.

-

Doesn't reserve future supply, such as supply that's scheduled to be built.

-

Reserves supply for each fulfillment line.

-

Reserves the entire quantity on the fulfillment line.

-

You can't reserve only part of the quantity.

-

If the entire quantity isn't available in inventory, then the reservation task doesn't reserve any quantity.

For example, if the quantity on fulfillment line x for item AS54888 is 4, and if there's only a quantity of 3 in inventory, then the reservation task doesn't reserve any quantity.

-

-

Reserves only from inventory that's currently available. It doesn't reserve according to date. It reserves from current inventory even if your sales order includes a scheduled ship date that happens in the future.

-

Automatically reserves each item where you set the Reservable attribute and the Back-to-Back Enabled attribute to Yes for the item in Product Information Management.

-

Reserves items that aren't configured and items that are configured.

-

Reserves all items in each assemble-to-order model, pick-to-order model, kit, or ship set together. It doesn't reserve individual items or only some items in each model, kit, or ship set.

Assume you sell a desktop computer as a model, and the model includes the CPU, memory, hard drive, monitor, keyboard, and mouse. If inventory has everything in stock except the memory, then the task doesn't reserve anything.

You can't reserve.

-

Coverage, such as a warranty for a desktop computer

-

Subscription, such as a magazine subscription

-

Item that a lot or serial controls from a specific lot or a specific set of serial numbers

-

From a specific subinventory.

-

Through a web service.

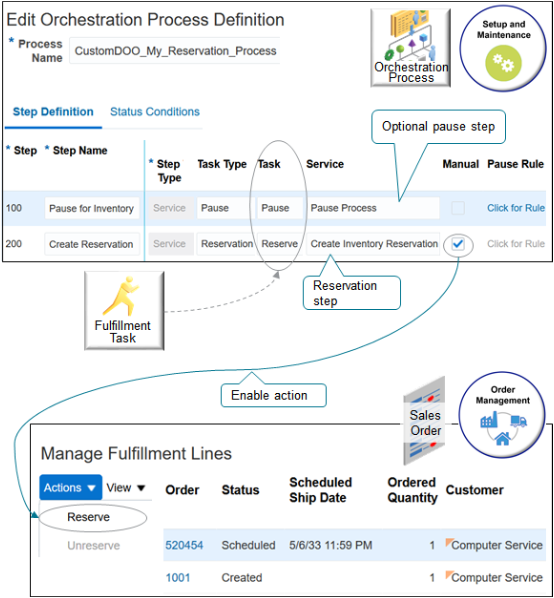

Set Up Your Orchestration Process

The predefined DOO_OrderFulfillmentGenericProcess orchestration process comes already set up with a step that references the create reservation task. Use it to automatically reserve inventory.

-

Reserve only according to quantity.

-

Your flow must provide the item, quantity, unit of measure, and warehouse.

-

Reserve the total requested quantity or it fails. You can't use it to reserve only part of the quantity.

-

It doesn't consider the requested date.

Use DOO_OrderFulfillmentGenericProcess or create a copy of it, then add an optional pause step.

Note

-

Use the pause step to pause the orchestration process until the shipment is almost ready to ship.

-

The reservation step will provide a more accurate picture of supply that's available because its closer to the ship date.

-

Waiting to reserve supply can also reduce the cost of holding inventory until its time to ship.

If you.

-

Enable the Manual Attribute on any step in the orchestration process. Order Management enables the Reserve action on the Management Fulfillment Lines page and waits for you to manually reserve the fulfillment line.

-

Don't enable it on any step.. Order Management disables the Reserve action and the process doesn't wait for you to manually reserve the fulfillment line.

The step details in the graphic might be a little hard to read. Here are the same details.

|

Step |

Step Name |

Step Type |

Task Type |

Task |

Service |

Manual |

|---|---|---|---|---|---|---|

|

100 |

Pause for Inventory |

Service |

Pause |

Pause |

Pause Process |

Doesn't contain a check mark |

|

200 |

Create Reservation |

Service |

Reservation |

Reserve |

Create Inventory Reservation |

Contains a check mark |

Reserve Supply Automatically for Your Item

Try it.

-

Set up your item in Product Information Management.

-

Go to the Product Information Management work area.

-

On the Product Information Management page, search for your item, then open it for editing.

-

On the Edit Item page, click Specifications.

-

Click Inventory, then set the attribute.

Attribute

Value

Reservable

Yes

-

Click Sales and Order Management, then set the attribute.

Attribute

Value

Back-to-Back Enabled

Yes

-

-

Add a reserve step to your orchestration process.

Reserve Supply Manually for Your Item

Try it.

-

In the Order Management work area, click Tasks > Manage Fulfillment Lines, then search for your fulfillment line.

-

In the search results, in the General Tab, click the link next to Orchestration Process Number, such as 300100181483263.

-

On the Orchestration Process page, click Fulfillment Lines.

-

Click Actions > Reserve.

If you encounter an error, it could be that there's a hold on the line and you need to release it. For details, see Schedule Fulfillment Lines Manually.

Use Global Order Promising

Use Global Order Promising to reserve supply.

-

Global Order Promising is an application that collects supply data from a planning system and promises to reserve the supply it collects.

-

Supply isn't physical inventory. Its planned supply that the factory hasn't built yet.

-

You can set up Global Order Promising to account for expected future supply and to split a fulfillment line.

-

The reservation service in Order Management doesn't consider future supply. It only reserves from on-hand inventory.

-

If you use Global Order Promising to reserve future supply, then don't use the reservation service in Order Management. Use one or the other, but not both at the same time.

There's a trade off between using Global Order Promising or the reservation service in Order Management. If there isn't enough supply to fulfill the line by the request date, and if you set the Allow Partial Shipments of Lines attribute on the line to Yes, then.

-

The scheduling service in Global Order Promising will split the line into two lines. The second line will contain a future date.

-

The reservation service in Order Management never splits the line, so it fails.

If you use Global Order Promising to schedule your fulfillment lines, then consider removing the reserve step from your orchestration process. If you must keep the reserve step, or if you don't use Global Order Promising, then.

-

Enable the Manual property on the step so you must click a button when close to the request date.

-

Only send lines to the reservation step that you can fulfill with the inventory that you have on hand. Or use a pause step to pause lines that you can't fulfill from on-hand inventory. The pause delays the reservation until nearer the request date.

Another option is to remove the reserve step and let shipping handle reserving inventory.