Plan for Pick-to-Order Kits

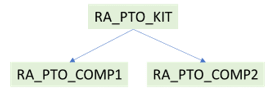

A Pick-To-Order (PTO) kit consists of a predefined list of mandatory components or items commonly referred to as standard bill of materials.

When processing a customer sales order, these components are picked, packed, and shipped together. An example of a PTO kit is a motor car maintenance kit that consists of essential tools such as wrenches and jack.

A PTO kit shouldn’t be confused with a PTO model. PTO kit is defined as an item with fixed components that displays the item structure and doesn't have options and classes.

How to Set Up a PTO Kit

- Create an item in the Product Information Management work area.

- Select the item to edit the attributes.

- On the Edit Item page, select the Specifications tab.

- Define the following attributes for the item:

Item Organization: Manufacturing - Pick Components: Yes

- Structure Item Type: Standard

Item Organization: Sales and Order Management - Customer Ordered: Yes

- Transfer Orders Enabled: No

- Order Management Transaction Enabled: Yes

- Shippable: No

- Ship Model Complete: Yes

How Supply Planning Considers PTO Kits

- When a sales order is created for a PTO kit, Oracle Order Management automatically generates sales order lines for all its components. As a result, planning doesn’t need to explode the bill of materials to create dependent demands for the components associated with the PTO kit.

- The sales order on the PTO kit consumes the forecast and the remaining forecast is exploded by supply planning. This is the case even if the plan option Explode Model Forecasts isn’t selected, because Oracle Demand Management doesn’t provide the forecast for standard mandatory components including the PTO kit components.

- The PTO kits are nonstockable and nontransactable and hence any existing supply created on PTO kit is ignored by supply planning. The supplies on components of a PTO kit are considered by supply planning as they're standard items.

- Order modifiers on PTO kits aren’t considered.

- It isn't recommended to create a work definition on PTO kits. If it’s needed for costing purposes, then assign the operation resources with Scheduled option set to No.

- A PTO kit under a PTO kit parent, or PTO or ATO model isn't currently supported.

Let's look into some examples.

Use Case 1:

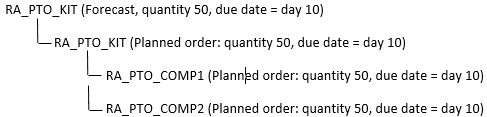

Consider the following PTO kit:

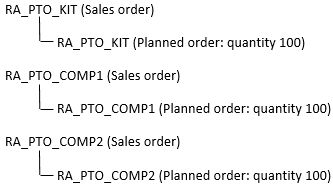

- Sales order on RA_PTO_KIT (quantity 100)

- Sales order on RA_PTO_COMP1 (quantity 100)

- Sales order on RA_PTO_COMP2 (quantity 100)

To satisfy the sales order on RA_PTO_KIT, a planned order is created by Supply Planning. A supply plan (constrained or unconstrained) doesn’t explode the planned order that's originating from a sales order on a PTO kit, to its components. In this case, planned order demands aren't created for RA_PTO_COMP1 and RA_PTO_COMP2. Separate planned orders are created for each sales order line.

Hence in this example, the following supplies are created:

Use Case 2:

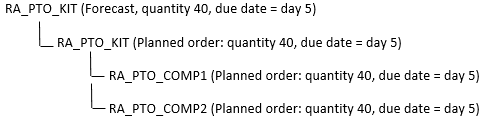

If there are forecasts on a PTO kit, the planned orders created to satisfy it are further exploded to its components.

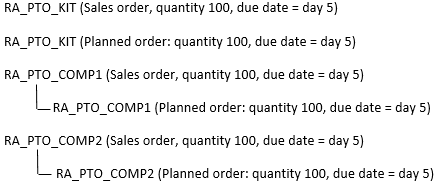

Consider the same setup as of use case 1, there's a sales order on day 5 of quantity 100, and there are forecasts on day 5 and day 10 of quantity 140 and 50 respectively on RA_PTO_KIT. The backward and forward consumption days is set to 1.

The sales order on the PTO kit consumes the forecast and the remaining forecast is exploded by supply planning. This is the case even if the plan option Explode Model Forecasts isn’t selected, because Demand Management doesn’t provide the forecast for standard mandatory components.

In this case, the sales order consumes the forecast on PTO kit on day 5 and the remaining forecast is exploded. The forecast on day 10 also explodes to its components.

The demand and supply picture after running a supply plan:

On day 5, the forecast of quantity 140 is consumed by the sales order on PTO kit and remaining forecast is planned by supply planning as:

On Day 10, because there's no consumption of forecast, whole quantity is planned by supply planning. The planned order on PTO kit is further exploded into kit components.