Shipment Management

Axle Weight Calculation for Rail Cars

This page allows you to understand the calculation of axle weight for rail cars during the equipment packing.

Axle Weight for Rail Equipment

The calculation of axle weight for rail equipment is a matter of public safety. The Axle Weight is a requirement for safe carriage as rail carriers demand that shippers tender safe loads and have the means to prove that the loads are safe. This is done either by a certified scale or is done by an approved calculation. Shippers with a Shippers Weight Agreement do not have to weigh each car as they can certify that the packing for the freight has been calculated and is within limits. Another requirement is that there is also a “balance” between the two supporting points. This Help Topic describes how OTM supports the calculation of these important metrics.

Axle Weight Calculation for Rail Equipment

OTM will calculate the axle weights for the rail cars after it determines how the equipment will be loaded. These values are persisted on to shipment equipment so that you can view those values. Also you can compare these axle weights against given Maximum axle weight allowed and set a STATUS on shipment equipment accordingly.

This logic is designed for rail cars with two "Trucks" (wheel assemblies, or "Bogies").

The Truck Weights indicate that portion of the total weight of the equipment, including freight, that is weighing down on each truck. The sum of the Truck Weights will be the same as the total weight of the equipment, including freight. For example, a loaded rail car has a total weight of 250,000 lbs including the equipment tare weight and the weight of the freight. In this rail car, the freight is loaded in such a way that the Truck A Weight is 120,000 lbs and the Truck B Weight is 130,000 lbs. (Thus the Truck Weight is not the weight of the wheel assembly. These wheel assembly weights would be included in the Equipment Tare Weight.)

The logic will compute the Truck Weights for the two trucks (Truck A and Truck B), the Axle Weights for the axles on each of the two trucks, and the Axle Weight Imbalance, under the following assumptions:

- The rail car equipment is perfectly symmetrical with respect to the Equipment Tare Weight, and with respect to the positions of the two trucks.

-

- The Equipment Tare Weight is thus applied at the exact center of the equipment.

- When not using 3D Load Config, the total weight of the items in each compartment are applied at the exact center of the compartment.

- When using 3D Load Config, the weight of each item is applied according to the position of that item.

- Each Truck Weight is distributed evenly over the axles of that truck.

The two Truck Weights are computed using standard moment of force calculations, based on:

- the Equipment Length of the Equipment Group,

- the Truck Center Length of the Equipment Group,

- when not using 3D Config:

- the center position of each compartment,

- the total weight of the items in each compartment,

- when using 3D Load Config:

- the position of each item,

- the weight of each item,

- the Equipment Tare Weight of the Equipment Group (that is, the empty weight of the equipment).

Note: The Rail Axle Weight Calculation does not use the axle distance table on the Equipment Group. Instead, it uses the following Equipment Group fields: the Tare Weight, the Truck Center Distance, the Equipment Truck Count, the Equipment Axle Count, and the Maximum Axle Weight.

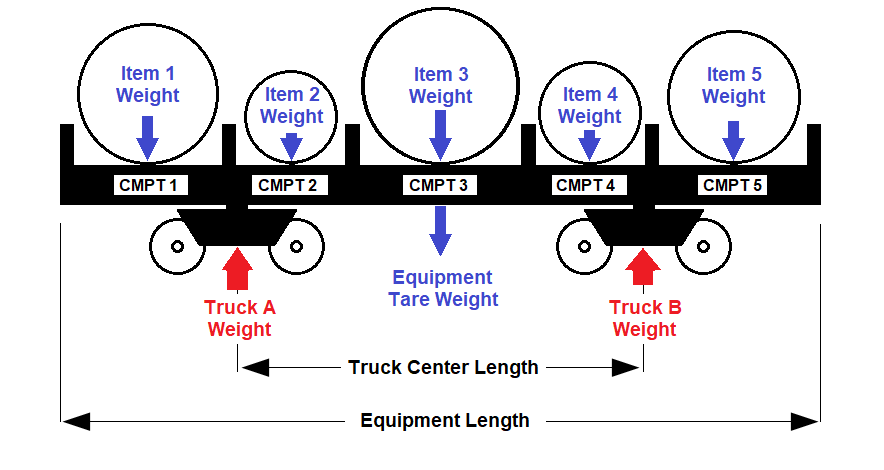

The following example illustrates the items weights, compartment positions, equipment tare weight, truck positions, and the resulting truck weights, for a symmetrical rail car with five compartments (e.g., "CMPT 1"), each compartment holding a single coil lying in a transverse position. The Total Axle Count for the equipment is four (two for each truck). While the rail car equipment itself is assumed to be symmetrical by itself, the weights of the items packed onto the equipment are not assumed to be symmetrical, and typically will not be. Unless the items in the compartments perfectly balance each other, the Truck A Weight will not be the same as Truck B Weight.

The Equipment Tare Weight is applied at the exact center of the equipment. Each item weight is applied at the exact center of its compartment.

The Truck Weight for each truck is computed by the summation of Moments around the center point of that truck.

The Axle Weight for each truck is computed simply as the Truck Weight divided by the number of axles per truck (i.e., divided by half the equipment Total Axle Count).

Axle Weight Imbalance

The Axle Weight Imbalance is calculated as the ratio:

- Truck A Weight / Truck B Weight (if Truck A Weight is smaller)

- Truck B Weight / Truck A Weight (if Truck B Weight is smaller)

The imbalance ratio will always be between 0 and 1.0.

Rail Axle Weight Status

The Container Optimization logic parameter RAIL AXLE WEIGHT IMBALANCE THRESHOLD is used to set a new RAIL AXLE WEIGHTS status on the Shipment Equipment. The logic will set the status value based on the Shipment Equipment's Axle Weight Imbalance, the Shipment Equipment's Truck Axle Weights, and the Equipment Group's Maximum Axle Weight.

The possible status values are

- RAIL AXLE WEIGHT NOT CALCULATED ( Default Value when axle weights not calculated )

- RAIL AXLE WEIGHT FEASIBLE ( No calculated Truck Axle Weight exceeds the Maximum Axle Weight)

- RAIL AXLE WEIGHT FEASIBLE BUT IMBALANCED (No calculated Truck Axle Weight exceeds the Maximum Axle Weight, but the imbalance ratio is less than defined threshold denoted by logic parameter "RAIL AXLE WEIGHT IMBALANCE THRESHOLD" )

- RAIL AXLE WEIGHT INFEASIBLE (At least one calculated Truck Axle Weight exceeds the Maximum Axle Weight)

Note: The axle weight calculation can be skipped in the below scenarios:

- If the Maximum Axle Weight on the equipment group is missing

- If the Truck Center Length on the equipment group is missing.

- If the Equipment Truck Count or Equipment Axle Count on the equipment group is missing.

- If the Equipment Truck Count is not equal to 2.

The Axle Weight Aware Packing algorithm finds an item-compartment configuration that has feasible axle weights and feasible axle weight imbalance ratio. The algorithm only works for the following cases:

- When there is only one item per compartment.

- The equipment has compartments set up.

- The axle weights can be calculated for the equipment.

- The number of compartments does not exceed the value in the property

"glog.optimization.packingsolver.maxCompartmentsForAxleWeightPacking".

The parameter 'RAIL AXLE WEIGHT AWARE PACKING' is used to enable or disable Axle Weight Aware Packing algorithm to attempt to generate an Axle Weight Feasible solution”

Note: This type of packing will only work if the packing is done in the one item - one compartment fashion and the equipment has compartments set up. If the packing algorithm doesn’t find an axle weight aware solution, the solution with the best axle weight imbalance ratio will be returned instead. The Shipment Equipment status will also be marked accordingly.

Axle Weight: Static and Calculated Values

With respect to axle weight, the Shipment Equipment manager will show static values obtained from the Equipment Group:

- Truck Center Distance

- Equipment Truck Count

- Equipment Axle Count

- Maximum Axle Weight

and the calculated value for that specific Shipment Equipment:

- Truck A Weight

- Truck A Axle Weight

- Truck B Weight

- Truck B Axle Weight

- Axle Weight Imbalance

The RAIL AXLE WEIGHTS status can also be obtained from the Shipment Equipment.

Note: When you assign an equipment to the shipment equipment, OTM will copy the rail axle weight information details to the shipment equipment and re-calculate the rail axle weights based on the new values fetched from the assigned equipment.