Creating Shipment Types

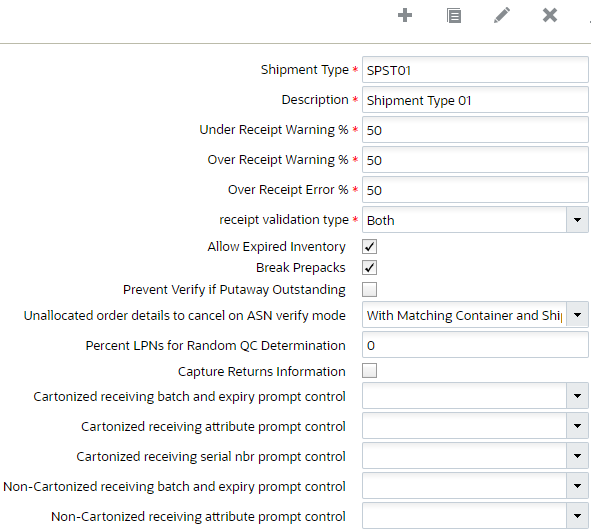

- Go to the “Shipment Types” screen and click the Create button.

- Check the appropriate flags for the ASN Type.

Description of fields

ASN Field Description Shipment Type The unique ASN/Shipment type code. Description Description of the ASN type. Under Receipt Warning % Field used to determine when the system should throw a warning message when an ASN item is under-received below the configured percentage. This warning message is displayed during ASN verification. Over Receipt Warning % Used to display a warning message when the user over-receives the ASN detail by above the defined % value. The user may choose to override this message. Over Receipt Error % Used to display an error message when the user over-receives the ASN detail by the defined %. The user cannot override this message. Receipt Validation Type If this field is selected, users can configure at what level the validation (from three previous fields) is required, whether at the PO, ASN or both. Allow expired inventory If set to yes, the system will prevent expired inventory from getting allocated, picked, substituted or shipped. Break Prepacks If the shipment's IB Shipment Type has the 'Break Prepacks Flag' set to True, the system will break all shipment details that have parent items into their corresponding children based on the definition in the 'Item Prepack' table. Prevent Verify if Putaway Outstanding If the 'Prevent Verify if Putaway Outstanding' flag is set to TRUE, the application will prevent verifying the corresponding shipment before all the received LPNs have been putaway. Unallocated order details to cancel on ASN verify mode Controls the behavior of cancelling an order line associated with a required LPN number when the corresponding LPN is part of the shipment but not received. Percent LPNs for Random QC Determination Used to determine which Inbound LPNs are marked for QC. If the shipment type is not present in the system or Percent LPNs for Random QC Determination is zero, then the Vendor QC Rule configuration will determine which Inbound LPNs should be marked for QC (upon selecting the action button "Perform Inbound QC Check".) Capture Returns Information If the shipment type has "capture_return_info_flg" set to Yes and Returned from Information is not captured, the system will not allow you to create an ASN. The system will throw error message "Shipment type is configured to capture returns information" after you click save. Cartonized receiving batch and expiry prompt control Blank/ Prompt, if not known/Always prompt/ Do not prompt. Allows you to configure the batch and expiry prompts at the individual shipment level for cartonized ASNs. Cartonized receiving attribute prompt control Blank/Prompt, if not known/Always prompt/ Do not prompt. Allows you to configure the receiving attribute prompts at the individual shipment level for cartonized ASNs. Cartonized receiving serial number prompt control Blank/Prompt, if not known/Always prompt/ Do not prompt. Allows you to configure the receiving serial number prompts at the individual shipment level for cartonized ASNs. Non-cartonized receiving batch and expiry prompt control Blank (Default behavior)/ Prompt, if not known/Always prompt. Allows you to choose whether to prompt for multiple batch/expiry/Attribute/serial for a single SKU in a non-cartonized ASN. Non-cartonized receiving attribute prompt control Blank (Default behavior)/ Prompt, if not known/Always prompt. Allows you to choose whether to prompt for multiple batch/expiry/Attribute/serial for a single SKU in a non-cartonized ASN.

For fields d, e, and f, the value entered is NOT the cut off point for triggering the warning/error messages.

- For under receipt, the RF will only trigger the warning message if receiving BELOW the inputted value.

- For over receipt, the RF will only trigger the warning/error message if receiving ABOVE the inputted value.

EXAMPLE

- ASN ships 100 units of ITEM1.

- Under Receipt Warning % = 10%.

- Over Receipt Warning % = 10%.

- Over Receipt Error % = 20%.

RESULTS:

- If the user receives 89 units, the RF will display an under-receipt warning message.

- If the user receives 110 units, the RF will not display an over-receipt warning message.

- If the user receives 111 units, the RF will display an over-receipt warning message.

- If the user receives 120 units, the RF will not display an over-receipt error.