Work Order Status

You can recalculate Work Order statuses automatically to reflect real-time inventory and activity conditions via Work Order Interface to ensures that discrepancies are minimized by aligning system status with real-time conditions.

NOTE: This button is permission-controlled; users must enable the permission at the group level to access it.

The system recalculates the Work Order status according to the following rules:

| Work Order Header Status | Conditions |

| Created | No allocations for the Work Order. |

| Partly Allocated | Partial allocations exist but are less than the required quantity. |

| Allocated | Allocations meet or exceed the required quantity, but replenishment has not started. |

| In Picking | Replenishment starts after full allocation, but picking is incomplete. |

| Picked | Picking is complete but Work Order processing is not started. |

| In Progress | Work Order Kit Process has started but is incomplete. |

| Completed | Work Order Kit Process is complete, and all required quantities are fulfilled. |

| Canceled | All required quantities are zero. |

Steps to enable:

- In the Work Order Inquiry screen, select the desired Work Orders.

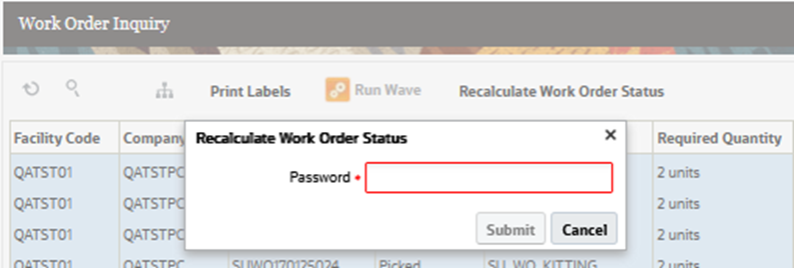

- Click the Recalculate Work Order Status button.

- Enter your password when prompted.

- Click Submit.

Upon successful verification, the system recalculates the status for the selected Work Orders based on the current conditions.

After recalculating, the system displays a message indicating the results:

"Status recalculated for X of Y Work Orders"

- X: The number of Work Orders successfully updated.

- Y: The total number of selected Work Orders.

Note: The recalculation process ensures that Work Order statuses accurately reflect

real-time conditions, such as inventory allocations, picking progress, and

completion.