Modify Ordered Quantity for Allocated or Partly Allocated Orders

While adjusting inventory within the existing orders (Allocated/Partly Allocated) to remove or add specific items, you can modify the ordered quantity for “Partly Allocated” and “Allocated” orders in the Order Detail UI. This gives you greater flexibility to update the ordered quantity, based on your requirements. Also, during inventory shortages or backorders, to cancel, and add new Order lines for an order, you can change the order lines after allocation.

To modify the ordered quantity for an Allocated or Partly Allocated order, do the following:

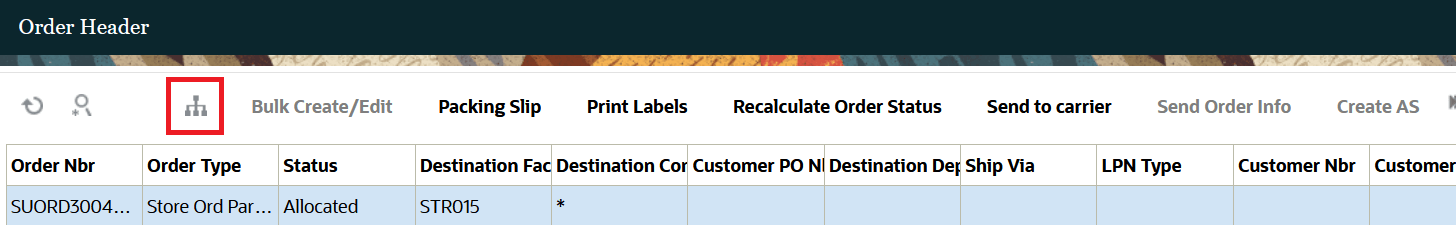

- Go to the Order Header (OrderHdrView) UI.

- Select an order in “Allocated” or “Partly Allocated” status.Note:

- You can also update ordered quantity for orders that are in created status.

- For a partly allocated order, you can increase or decrease the ordered quantity. If the updated ordered quantity equals to the allocated quantity, then the system updates the order status to Allocated or other status based on the order detail status. Note that, you are not allowed to decrease the ordered quantity less than the allocated quantity.

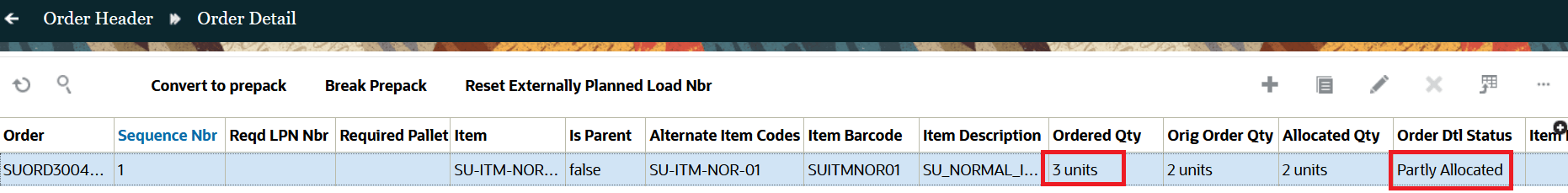

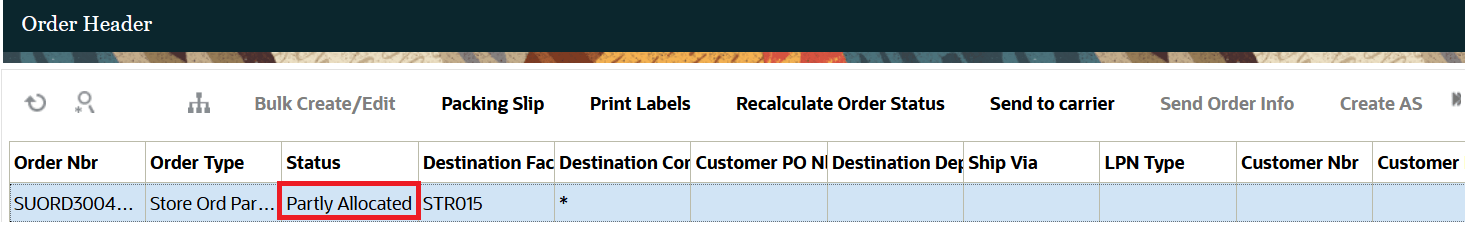

- For an allocated order, you can only increase the ordered quantity. If you update the ordered quantity more than the allocated quantity, then the system updates the order status to “Partly Allocated”.

- Click Details action button to navigate to the Order Detail screen.

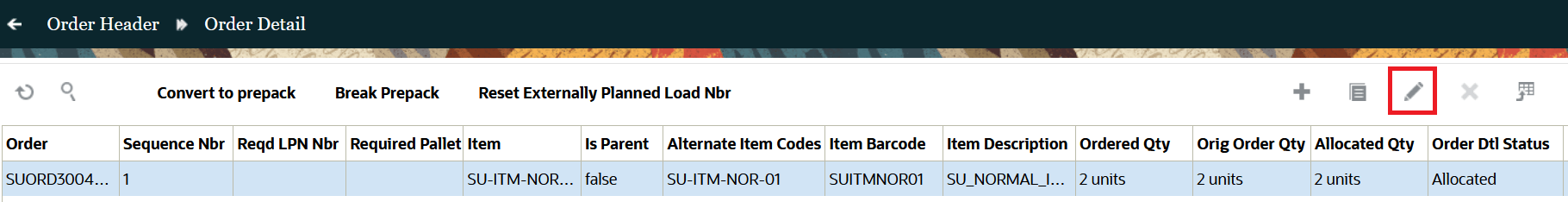

- In the Order Detail screen, select an order detail record to update ordered

quantity and click Edit action button.

- Update the Ordered Quantity based on your requirement.

- Click Save.Note:

- Updating ordered quantity is not supported for transportation split orders. The system prompts you with an error message “Cannot modify order quantity which has gone through transportation split.”

- On updating ordered quantity less than the order’s allocated quantity, the system prompts with an error message “Cannot modify order quantity to less than allocated quantity”.

- If the order detail is populated with the “Requires serial Nbr” field, the system does not allow you to update the ordered quantity for a serial tracking item . If you proceed further, the system errors “Cannot modify order quantity for order detail having required serial number”.

The system updates the Order Detail status based on the updated Ordered Quantity as shown in the figure below:

And the Order Header screen displays the updated order status based on the order detail status.

To add or delete order details for an Allocated or Partly Allocated order, do the following:

- Go to the Order Header (OrderHdrView) UI.

- Select an order in “Allocated” or “Partly Allocated” status.Note:

- You can also add or delete order lines for orders that are in created status.

- For a partly allocated order, you can add or delete order lines. If you delete an order line and made order’s ordered quantity equals to the allocated quantity, then system updates the order status to Allocated or respective other status based on the order detail status.

- For an allocated order, you can only add a new order line. If you create a new order line, then system updates the order status to “Partly Allocated”.

- Click Details action button to navigate to the Order Detail screen.

- In the Order Detail screen,

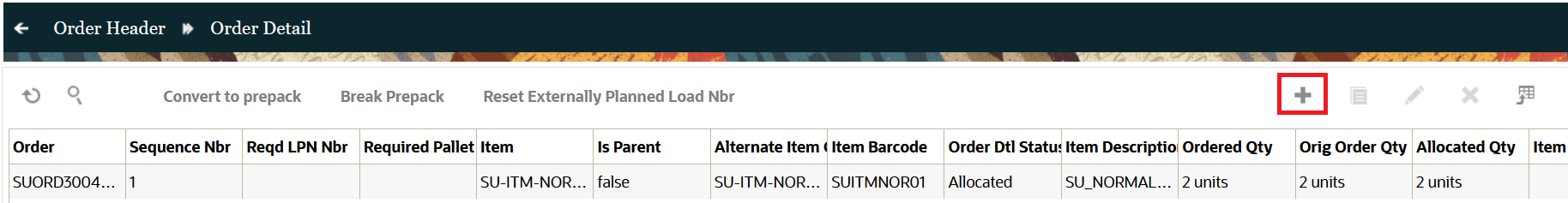

- To add a new order line:

- Click Create action button.

- On the create pane, based on your requirement, add details and click Save.

- Click Create action button.

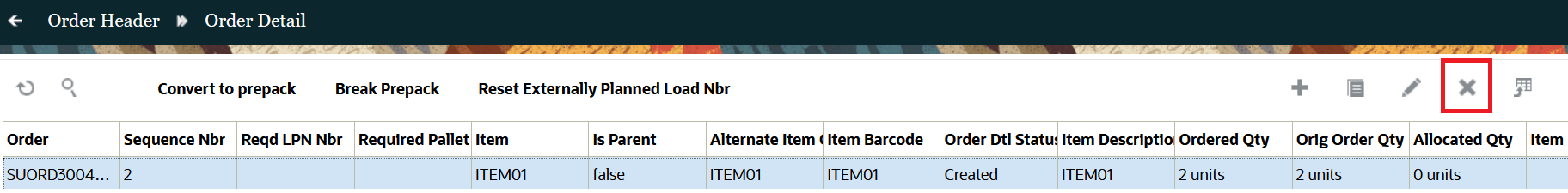

- To delete an order line:

- Select the order line to delete and click Delete action

button.

Note: You can delete the order detail only if the if the order detail is unallocated.

Note: You can delete the order detail only if the if the order detail is unallocated. - Select the “Reason Code” in the Delete pop-up and click

Submit.Note: On deleting an order detail having transportation split and in “Created” status with more than one split order details with allocations, after entering the Reason code prompt, the system displays an error message “Cannot delete order detail which has gone through transportation split.”.

The order status will be updated in the Order Header based on the inclusion or exclusion of the order details.

- Select the order line to delete and click Delete action

button.

Navigate back to Order Header screen and observe that the Order Status changed based on the inclusion or exclusion of order details.

- To add a new order line:

When you update the ordered quantity or delete an order detail, the system updates the following Inventory History Transactions in the Inventory History UI:

| IHT Transaction | Trigger Point |

|---|---|

| 20 - Order Status Change | When the order status changes from Partly Allocated to Allocated / Packed / Picked / Loaded / Shipped or Allocated to Partly Allocated. |

| 85 - Order Detail Status Change | When the Order Detail status changes from Partly Allocated to Allocated / Packed / Picked / Loaded / Shipped or Allocated to Partly Allocated. |

| 27 - Order Cancellation | When an existing or new order detail is deleted. |

To support the Order Header and Order Detail UI updates, the Order Interface and Order entity for INIT_STAGE_INTERFACE API enables:

- Add a new inventory line and delete an unallocated inventory line.

- Update the ordered quantity for Partly Allocated and Allocated orders.

- On updating ordered quantity less than the order’s allocated quantity in the Order Interface, the system alerts you with an error message “Cannot modify order quantity to less than the allocated quantity for <SKU> with order sequence <sequence number>.”.

- On updating ordered quantity for a transportation split order via the Order Interface, the system alerts you with an error message “Order <Order Number> with sequence number <sequence number> is part of OTM transportation split, cannot modify order qty.”.

Enhancements to Predefined Integration to Support Quantity Changes for Partly Allocated/ Allocated Orders

You can modify order quantities even when an order has reached the Partly Allocated or Allocated stage, if the items haven’t been packed. This provides greater flexibility in managing orders, particularly for systems using WMS Prebuilt Integration.

You can lock and unlock orders using the Order Lock API and Order Unlock API, perform updates, and unlock the order to continue processing.

Note: The change cannot be made for orders that have already been picked or packed. This helps the shipping process remains error-free and avoids disruptions caused by changes at later stages.

To enable and update order quantities for partly allocated or allocated orders, do the following:

- Confirm that the order is in the Partly Allocated or Allocated stage.

- Check if the items in the order have not yet been packed.

- Use the Order Lock API to lock the order and modify the order quantities as required.

- Once the updates are complete, use the Order Unlock API to release the order for further processing.