Item Driven Cycle Count

You can create customized cycle count tasks for specific items to accommodate counting specific items based on the item characteristics in a location. This optimizes the overall operations and inventory accuracy.

Cycle count for specific items in a location focuses on specific items instead of all items available in that location. You can plan cycle count tasks based on item attributes like counting specific items a certain number of times per year based on their velocity code or other specific attributes.

This helps you to:

- Create cycle count tasks for specific items, reduce non-essential counts, and increase the productivity.

- Create cycle count tasks for specific items that generates tasks for all locations where the SKU is located at that time.

Item-Specific Cycle Count Tasks Creation

To create item-specific cycle count tasks, do the following:

- Go to Task Creation Template (TaskCreationView) UI.

- Click the

(Create) icon to create a CC Task template.Note: You can edit the previously created CC Task template also.

(Create) icon to create a CC Task template.Note: You can edit the previously created CC Task template also. - Select the created CC Task Template and click details icon.

- On the Task Creation Template > Details screen, click

(Create) icon and configure the task creation template details with

“CC-LOCN-BY-ITEM” task type.Note: You are not allowed to configure both “CC-LOCN-BY-ITEM” task type and either of the other cycle count task types (CC-LOCATION, CC-LOCATION-DTL, or CC-LOCN-LPN-CNT) in a single CC task template. If you configure both, the system displays an error message “Cannot mix item specific task type with other CC task types in a single template”.

(Create) icon and configure the task creation template details with

“CC-LOCN-BY-ITEM” task type.Note: You are not allowed to configure both “CC-LOCN-BY-ITEM” task type and either of the other cycle count task types (CC-LOCATION, CC-LOCATION-DTL, or CC-LOCN-LPN-CNT) in a single CC task template. If you configure both, the system displays an error message “Cannot mix item specific task type with other CC task types in a single template”. - To configure the item specific selection criteria for the CC task template,

select the “CC-LOCN-BY-ITEM” record and click Item Selection Criteria

action button. Post configuring the item specific selection criteria, click

Save.Note:

- Item selection Criteria action button is enabled only for the “CC-LOCN-BY-ITEM” task type and it is mandatory to configure for the “CC-LOCN-BY-ITEM” task type. For the “CC-LOCN-BY-ITEM” task type, the “Item Selection Criteria” action button lists all item specific attributes. Selecting “Item Selection Criteria” shortlists all the items matching the criteria and creates CC-LOCN-BY-ITEM cycle count task for those items.

- “Item Selection Criteria” column displays the selection condition provided in the “Item selection Criteria” action button.

- On the Task Creation Template > Details screen, to configure the

location specific selection criteria for the CC task template, select the

“CC-LOCN-BY-ITEM” record and click Selection Criteria action button. Post

configuring the location specific selection criteria, click Save.Note:

- For the “CC-LOCN-BY-ITEM” task type, the “Selection Criteria” action button lists all location specific filters. Also, “Selection Criteria” is non-mandatory to configure for the “CC-LOCN-BY-ITEM” task type. If you don’t provide the “Selection Criteria”, the system creates tasks for all locations where the shortlisted items are located at the time of running the task creation template.

- By default, the “Item Selection Criteria” and “Selection Criteria” columns are available on the data grid. If you uncheck either of these columns, the system excludes the unchecked criteria condition (though it is configured) for task creation. So, make sure that both “Item Selection Criteria” and “Selection Criteria” columns are available on the data grid.

- After configuring the CC Task Creation Template, on the Task Creation

Template UI, select the configured “CC-LOCN-BY-ITEM” task type task

template and click Run Template action button.

The system creates the item specific cycle count tasks for the matching items.

Note: If you run a CC type task creation template (configured with the “CC-LOCN-BY-ITEM” task type) without item selection criteria configuration, the system displays an error message “CC Template does not have an item selection rule”.

The system creates multiple CC-LOC-BY-ITEM tasks for a location, provided there is no common item for which an existing cycle count task is available for that location. Although multiple “CC-LOC-BY-ITEM” tasks can be created for the same location, if an existing “CC-LOC-BY-ITEM” task is in progress, the system restricts another “CC-LOC-BY-ITEM” task from executing for the same location.

The following table details the “CC-LOCN-BY-ITEM” task creation behavior when a location already has an existing item driven cycle count task:

| Existing Task Number | Cycle Count Location | Existing Task SKUs | Shortlisted New SKUs for "CC-LOCN-BY-ITEM" task creation | New Task Cycle Count Location | Behavior |

| TASK01 | LOC01 | ITEM01 | ITEM02 | LOC01 | The system allows “CC-LOCN-BY-ITEM” task creation for LOC01 with ITEM02. |

| TASK01 | LOC01 | ITEM01, ITEM03, ITEM05 | ITEM02 | LOC01 | The system allows “CC-LOCN-BY-ITEM” task creation for LOC01 with ITEM02. |

| TASK01 | LOC01 | ITEM01, ITEM03, ITEM05 | ITEM03, ITEM06 | LOC01 | The system restricts “CC-LOCN-BY-ITEM” task creation for LOC1 with ITEM03 and ITEM06. |

| TASK01 | LOC01 | ITEM01, ITEM03, ITEM05 | ITEM03, ITEM06 | LOC01, LOC02 |

The system restricts “CC-LOCN-BY-ITEM” task creation for LOC1 with ITEM03 and ITEM06. The system allows “CC-LOCN-BY-ITEM” task creation for LOC02 with ITEM03 and ITEM06. |

If a location has existing cycle count tasks for certain items, the system restricts the creation of new “CC-LOCN-BY-ITEM” tasks for the same items in that location. The system leverages existing tasks to avoid duplication, ensuring efficient task management and preventing unnecessary repetitions. If the system fails to create “CC-LOCN-BY-ITEM” tasks, it records CC logs “Location %s skipped. CC Task %s with same items exists.” for the skipped locations.

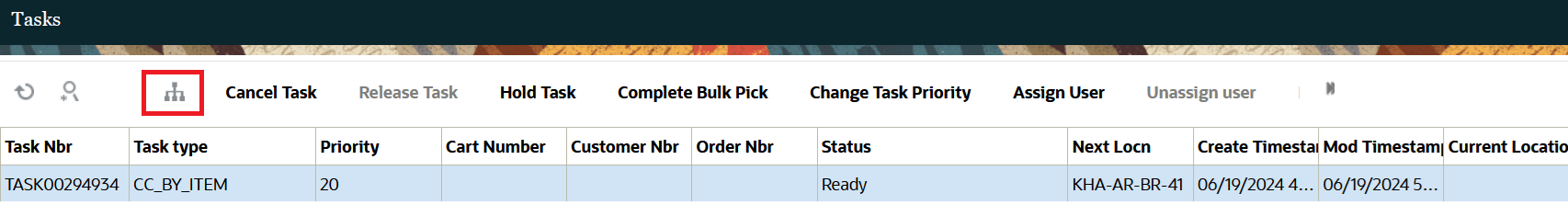

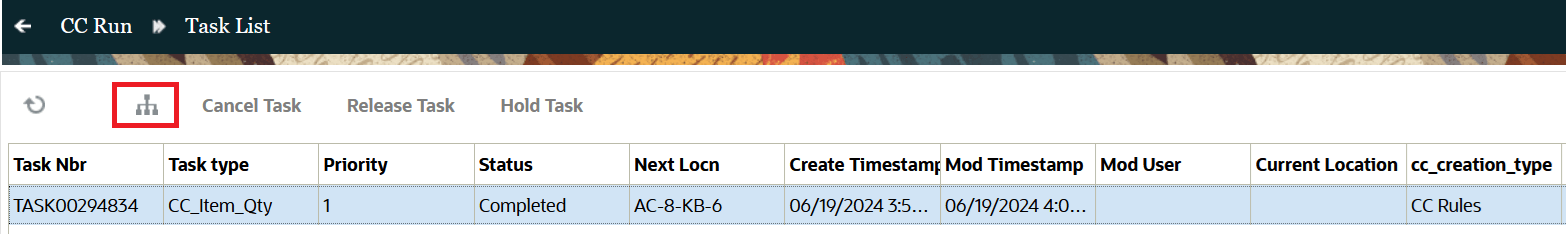

You can view the created item specific cycle count task details (specific items that are shortlisted based on the item selection criteria) on the Tasks (TaskView) > Task Detail screen or CC Run (CCRunView) > Task List > Task Detail screen. Also, when you run a CC task template, under the CC Run > CC Logs screen, you can view all sequential transactions done for that CC task template.

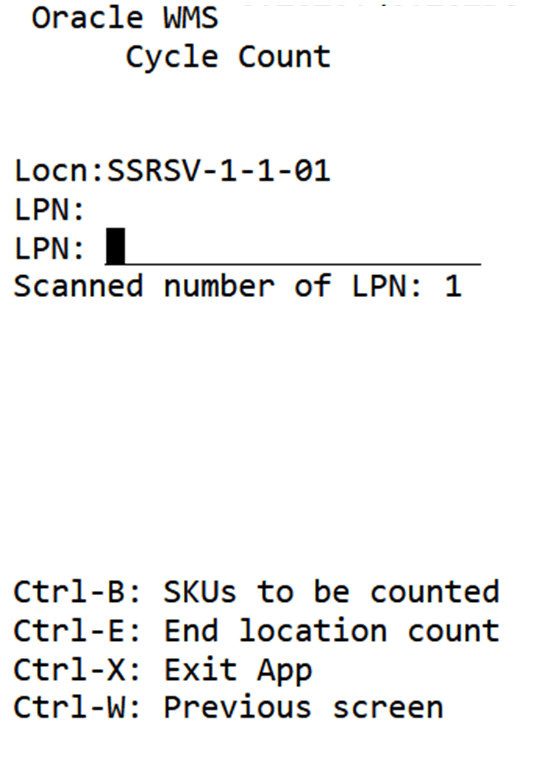

RF Cycle Count Location Screen Flow (Active Location)

- Launch the RF Execute Task (rf.outbound.cwrfexecutetask) transaction.

- Scan or enter the created item specific cycle count task number.Note: Executing multiple “CC-LOC-BY-ITEM” tasks simultaneously for a single location is not permitted. If a “CC-LOC-BY-ITEM” task is already in progress for a location, the system will not allow any additional “CC-LOC-BY-ITEM” tasks to be executed for the same location. In this case, if you scan the location, the system displays a hard error message “A CC-LOC-BY-ITEM task is already in progress for this location”.

The system redirects you to RF Cycle Count Location (rf.inbound.cwrfcyclecountlocn) transaction and navigates you through the counting process, prompting you with the SKUs to be counted.

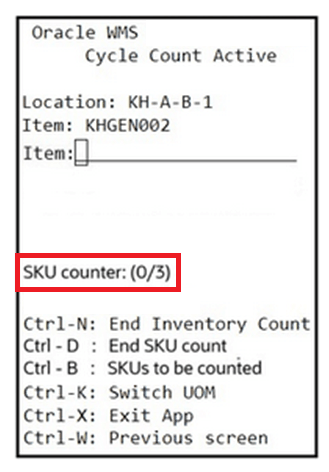

You can observe the scanned item count (unique SKUs that are counted/total number of unique SKUs in the task detail) in the SKU counter display.

- Scan or enter the item to confirm and proceed for counting.

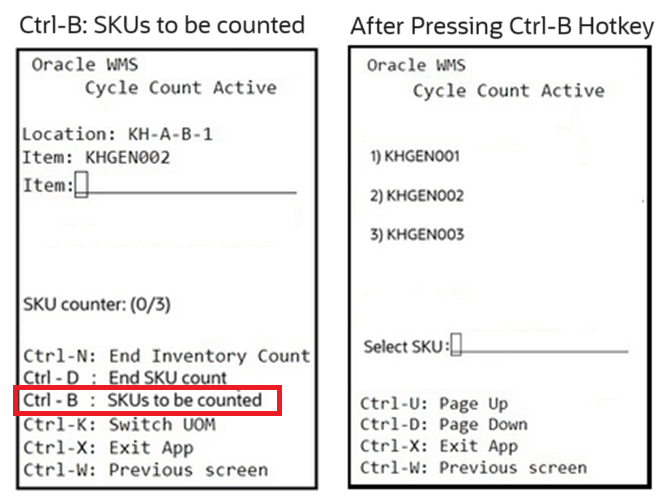

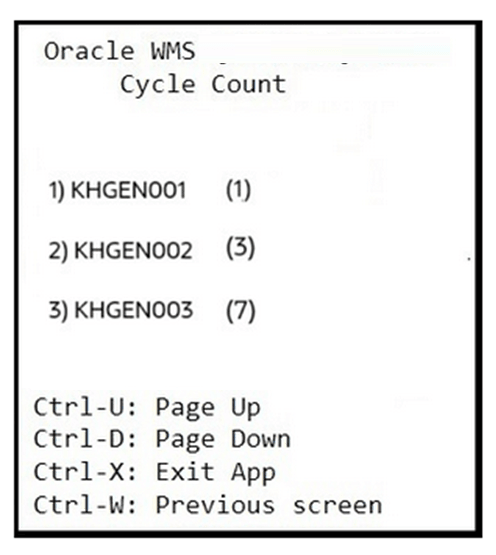

You can use Ctrl-B: SKUs to be counted hotkey to display all shortlisted SKUs present in the scanned CC-LOCN-BY-ITEM task detail.

You can enter the item index number (1,2, 3….) in the “Select SKU” field and proceed for cycle counting of that item.

- After counting a SKU, press Ctrl-D: End SKU count hotkey to end the count

for the SKU and proceed to count the next SKU present in the task

detail.

During the transaction, the system navigates you with the items to be scanned. Once you end the SKU count for a SKU, the system guides you to scan the next SKU.

Note: In SKU-Quantity mode, after ending the SKU count for the last SKU in a task, the system ends the task automatically. As this is a guided SKU counting, “CTRL-E: End location count” hotkey is not available for the “CC-LOCN-BY-ITEM” task execution. After counting all required SKUs in the task, the system auto closes the location count.

Key Notes for Consideration (“CC-LOCN-BY-ITEM” task):

- For the “CC-LOCN-BY-ITEM” task type, you can add an RF Cycle Count Location (rf.inbound.cwrfcyclecountlocn) screen only. If you add a screen that is not configured with the rf.inbound.cwrfcyclecountlocn module, the system alerts you with an error message “RF Screen is not created using the specific module”.

- During the transaction, if you scan an item that is not present in the executing task, the system displays a hard error “Scanned SKU is not in task”.

- During the transaction, when an SKU counting is in progress, without ending the in progress counting SKU, if you scan another SKU (present in the executing task), then the system displays an error message “Scanned SKU does not match with the SKU being counted”.

- If you scan a counted SKU during the transaction, the system displays a warning message “%SKU already counted. Do you want to override the count of this SKU?”.

- There is no impact of the screen parameter “update-locn-invn-mode” on the “CC-LOCN-BY-ITEM” task. If you scan an SKU (multiple inventory combinations), the system updates the unscanned inventory count to “0”.

- In SKU-Quantity mode, you are required to press CTRL-D hotkey to end the SKU being counted and to proceed for the next SKU prompt. Once all SKUs are counted from the list, pressing CTRL-D hotkey ends the cycle count task automatically. When screen parameter “qty-uom” is set to “infer UOM from item barcode”, the system displays both CTRL-N and CTRL-D hotkeys. The CTRL-N hotkeyallows you to end the inventory count of the SKU being prompted (SKU with the selected attribute combination) whereas CTRL-D ends the count of SKU being prompted.

- In SKU-Scan mode, ‘Total quantity counted’ label displays the quantity of specific SKUs that are being counted. Unlike the location level counting, the label does not show the total quantity count of all SKUs in a cycle count task. It displays the count only for the SKU in focus and gets reset after you press CTRL-D.

After performing the RF Cycle Count Location transaction with a “CC-LOCN-BY-ITEM” task, on the Cycle Count Adjustment UI, the system records the expected and counted quantities of SKUs (part of the “CC-LOCN-BY-ITEM” task) that are counted for the scanned location in deferred mode.

In the immediate mode, the system updates the inventory for the counted SKUs directly without any approval. In the immediate or deferred mode, the inventory updates are limited to shortlisted SKUs only.

To identify the cycle count adjustment approval records that are generated for an item specific cycle count, you can filter the cycle count adjustment approval records with “CC-LOC-BY-ITEM” task type using the Task Type filter in the Cycle Count Adjustment UI.

If you reject a count record, based on the Cycle Count trigger configuration, the system creates a CC type task (existing CC task types only not “CC-LOC-BY-ITEM” task type) for the location. For more details, refer Cycle Count Inventory Updates.RF Cycle Count Location Screen Flow (Reserve Location)

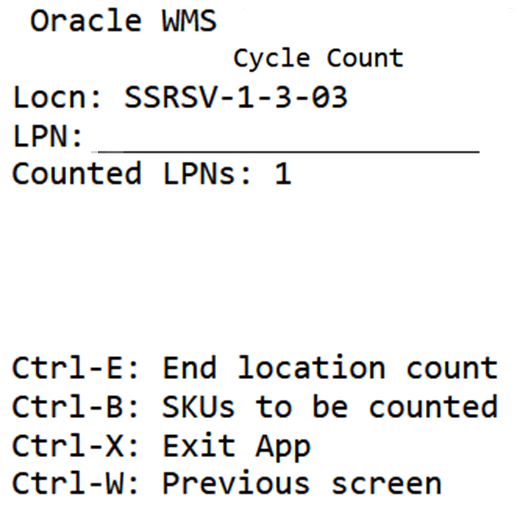

After creating “CC-LOC-BY-ITEM” tasks, you can perform cycle count for the shortlisted items in a reserve location. To perform cycle count for a reserve location, follow these steps:

- Launch the RF Execute Task (rf.outbound.cwrfexecutetask) transaction.

- Scan or enter the item specific cycle count task number.

The system redirects you to the RF Cycle Count Location (rf.inbound.cwrfcyclecountlocn) transaction.

- Scan or enter the location to confirm.

- Scan or enter an LPN.Note:

- For SKU-Qty and SKU-Scan modes, LPNs are not defaulted or guided.

- In LPN scan mode (default behavior or when the “content-count”

screen parameter is set to Blank), after scanning a Cycle Count

location, the system guides you to scan anticipated LPNs (physically

present in the scanned location). On counting the guided LPN, the

system increases the LPN count. For a multi-SKU LPN, counting the

LPN increases the inventories for all shortlisted SKUs present in

the scanned task detail. You can scan multiple guided LPNs to

complete the cycle count. If you are in LPN scan mode, you can skip

steps 5 to 8.

If you scan a new, cancelled, or unanticipated LPN in LPN scan mode, the system displays an error message.

- Scan or enter an item to confirm and proceed with the counting.Note: During the transaction, if you scan a SKU that is not in focus or display, the system displays an error “SKU count in progress, cannot override SKU”.

You can use the Ctrl-B: SKUs to be counted hotkey to view all shortlisted SKUs present in the scanned CC-LOCN-BY-ITEM task detail, along with the counted LPNs count next to each SKU.

- In SKU-Qty mode, scan or enter the quantity to confirm.Note: In SKU-Scan mode, you can scan the SKU multiple times depending on the available quantity.

- After counting a SKU, press Ctrl-D: End SKU count hotkey to end the count

for that SKU and proceed to the next SKU in the scanned LPN.

During the transaction, the system navigates you through the items to be scanned. Once you end the SKU count for one SKU, the system updates the counted LPNs and guides you to the next item scan.

- After counting all SKUs, press Ctrl-P: End LPN Content Count hotkey to

end the count for the scanned LPN and proceed to count the next LPN.

On completing the SKU count in an LPN, the system prompts you to scan the next LPN. You can observe the Counted LPNs count displayed in the transaction.

In the module rf.inbound.cwrfcyclecountlocn, if you enable the screen parameter “allow-new-lpn-scan”, you can scan new or cancelled LPNs in both tasking and non-tasking modes to perform detail level cycle count.

After scanning a cancelled or new LPN and accepting the warning message “Scanned LPN is not present in task, proceed?”, the system loops you through all the items present in the task detail. You can press Ctrl-D End SKU count hotkey to ignore a SKU that is not relevant to the LPN. Since you are scanning a new or cancelled item, post completion of cycle count, the system updates the expected quantity as “0”.

Key Notes for Consideration

- For both cancelled and new LPNs, after entering the quantity for each SKU, the system prompts you to recount the inventories.

- After counting a cancelled or new LPN, the system updates that corresponding LPN to Located status and creates records in the Reserve Inventory (in immediate mode). In deferred counting mode, the LPN will be created only when the corresponding CC adjustment records are approved.

- If a cycle count location has a lock code, the system inherits the lock code to the counted cancelled or new LPNs and the system records the inventory history transaction “IHT-23 - Lock Container - After ASN Verification”.

- During the cycle count, you can scan reusable totes associated with cancelled or new LPNs.

- In deferred mode, after counting a cancelled or new LPN, the system writes “Cancelled LPN counted” or “New LPN created” message respectively on the Cycle Count Adjustment Header (CCAdjustmentHdrView) and Cycle Count Adjustment Detail warning hyperlinks.

- For a “CC-LOCN-BY-ITEM” task, if you scan a new or cancelled LPN, the system displays a warning message “Scanned LPN is not present in task, proceed?”. You can change this warning message to a hard error to restrict the scanning of unanticipated LPNs.

You can scan unanticipated LPNs (LPNs that are not expected at the location) via item driven reserve location cycle count. In this case, the system loops you through all the SKUs in the scanned task detail. You can press Ctrl-D- End SKU count hotkey for any SKU that is not relevant to the scanned LPN and continue with the counting. For SKUs that are physically present in the scanned LPN, you can confirm the SKUs and proceed with the cycle count.

Note: Inventory adjustment updates are limited to counted SKUs only.The following table explains the Location and LPN-SKU combination scan behavior:

Scanned LPN Scanned SKU Behavior Anticipated for the Location to complete “CC-LOCN-BY-ITEM” task Scanned a SKU that is present in the task The system proceeds with cycle count (regular flow). Unanticipated for the location but present in the facility (LPN is physically present in location) Scanned a SKU that is present in the task The system displays a warning message “Scanned LPN is not present in task, proceed?”. You can update this warning message as a hard error to restrict unanticipated LPN scan. Upon scanning the system loops you through all the shortlisted SKU (present in a task detail) Anticipated/unanticipated in the cycle count location Scanned a SKU that does not present in the task The system displays an error message “Scanned SKU is not in task”. - After counting all LPNs, press Ctrl-E: End Location count hotkey to end

the count for the scanned location.

During the transaction, if you end the location count without counting all anticipated SKUs, the system displays a warning message “LPNs not counted will be marked as lost. Proceed further? %s”. For a multi-SKU LPN, if the anticipated SKUs (from the task detail) are not scanned, the system reduces the LPN inventories only for those SKUs. The system does not impact the LPN inventory for the SKUs that are not present in the task detail. When a multi-SKU LPN goes to lost status via item driven reserve location cycle count, the system updates the LPN inventories to 0.

Key Notes for Consideration

- Inventory adjustment updates are limited to filtered or shortlisted items (from the task detail).

- You can scan an anticipated SKU (present in the scanned task detail) to count for any scanned LPN in the CC-LOC-BY-ITEM task, even if the scanned SKU is unanticipated or not part of the scanned LPN.

- If you scan a SKU that has already been counted for the scanned LPN, the system displays an error message “%SKU already counted. Do you want to override the count of this SKU?”.

- If you skip confirming a SKU or end a SKU count without entering quantity, the system displays a warning message “Uncounted qty will be reduced from inventory for %SKU, proceed?”. On accepting the message, the system updates the inventory of that SKU to 0 for that LPN.

- Like an active location, the screen parameter “update-locn-invn-mode” does not affect the “CC-LOCN-BY-ITEM” task. SKUs that are not present in a CC-LOC-BY-ITEM task are not impacted for a location. However, you must scan all inventories of the SKUs present in the task detail. Otherwise, the system updates the uncounted inventories to 0 (applicable only to the shortlisted SKUs).

- You are allowed to scan Lost LPNs if the scanned LPNs contain shortlisted SKUs as per task detail.

- When the screen parameter “qty-uom” is set to “infer UOM from item barcode” the system displays both Ctrl-N and Ctrl-D hotkeys. Ctrl-N hotkeyallows you to end the inventory count of the SKU being prompted (SKU with the selected attribute combination) whereas Ctrl-D ends the count of the prompted SKU.

- Currently, pallet prompt is not supported for the item driven reserve location cycle counts. However, you can scan LPN as a physical pallet and LPNs within a pallet.

IHT Updates

On performing the RF Cycle Count Location (rf.inbound.cwrfcyclecountlocn) transaction, the system records the Inventory history transactions. To differentiate the cycle counting type, REF CODE 15 and REF Value 15 are available in the Inventory History transactions.

The system updates the values of fields REF CODE 15 and REF Value 15 based on the cycle count type as mentioned below:

| Column | Value |

|---|---|

| REF CODE 15 | “CCT (Cycle Count Type)” for 42-Cycle Count, 19- Inventory Adjustment, 37-Active Location Cycle Count Complete, 41 - Cycle Count - IBLPN Counted, 38 - Reserve Location Cycle Count Complete, 53 - Cycle Count - Reserve SKU Counted, 40 - IBLPN Lost, and 39 - Cycle Count - Lost IBLPN counted. |

| REF Value 15 |

|

Execute Simultaneous Item Driven Cycle Count Tasks for a Location

The system allows you to perform multiple item driven cycle count tasks for various items in the same location simultaneously. You can initiate counts for different items at various instances, regardless of any pending cycle count adjustments or in-progress item driven cycle count tasks for a particular location.

This helps you to:

- Quickly count various items in a single location through multiple cycle count tasks, irrespective of any pending cycle count adjustment records for that location.

- Perform precise inventory cycle counts, ensuring accuracy even in large locations.

- Prioritize counts based on attributes such as velocity code of item at different instances.

- Optimize counting schedules and avoid delays, resulting in a smoother cycle count process.

On configuring a CC task creation template, you can create multiple “CC-LOC-BY-ITEM” tasks for a location, if there is no item concurrency. Although, multiple “CC-LOC-BY-ITEM” tasks can be created for the same location, if an existing “CC-LOC-BY-ITEM” task is in-progress, the system restricts another “CC-LOC-BY-ITEM” task execution for the same location.

By default, if a location has a pending item driven cycle count approval, on executing a “CC-LOC-BY-ITEM” task for the same location, the system displays an error message “Cycle Count approval pending for the Location. Do you wish to proceed with the count?”. You can set this message as a warning and continue with the count if needed.

To enable simultaneous cycle counting for a location, irrespective of in-progress cycle count tasks or pending “CC-LOC-BY-ITEM” cycle count approvals, follow these steps:

- Go to Message Codes (MessageCodeView) UI.

- Configure the following messages as warnings.

Message Code Message 4669 Cycle Count approval pending for the Location. Do you wish to proceed with the count? 4328 A %TASK_TYPE task is already in progress for this location. To update a message as a warning, do the following:

- Select the message you want to edit.

- Click Edit Facility Message Config action button.

- In the “Edit Facility Message Config” pop-up:

- Select a Facility.

- Check the Enabled checkbox.

- Uncheck the Auto Reject checkbox.

- Click Submit.

Note: By default, the above error messages are set as hard error messages. Ensure that you have configured the above messages as warnings.

After configuring the above hard error messages as warning messages, you can accept the warning messages and proceed with the cycle count tasks.

On completing the tasks, the system updates the inventory or creates cycle count adjustment records in ascending order of task execution (if there is no item concurrency). The system creates multiple CC Adjustment header records per executed tasks. You can review the counted item inventory details in the Cycle Count Adjustment Details screen.

- Simultaneous cycle counting is applicable only for CC-LOC-BY-ITEM tasks through both RF and Cycle Count List API.

- Inventory updates are limited to the counted items within a location.

- The system updates inventory or creates cycle count adjustment records based on immediate or deferred mode.

- The system allows creation of multiple CC Adjustment Header records only for CC-LOC-BY-ITEM tasks. If a location has a pending cycle counting task, or cycle count adjustment records for the entire location (location driven count), the system doesn’t allow you to create/execute item driven cycle count task for that location.

- The system allows executing multiple item driven cycle count tasks for a location, as long as the same item is not pending for cycle count approval.

- The system creates multiple cycle count adjustment records for the same location (with different group numbers) when counts are from different cycle count run. You can multi-select the cycle count adjustment header records and perform approve/reject/cancel actions from the Cycle Count Adjustment Header. However, approving or rejecting a single header record may not release the CC Lock on the location, since multiple header records are created for a single location.

- Standalone location-level deferred counting is not permitted, if the location has pending cycle count tasks or cycle count adjustment approvals.

Example: Location has multiple “CC-LOC-BY-ITEM” tasks and the available inventory records have multiple SKUs with different attributes.

Location Inventory (Before Cycle Count):

| Location | SKU | Original Quantity | Current Quantity | Batch |

| LOC01 | SKU01 | 50 | 50 | BAT01 |

| LOC01 | SKU01 | 100 | 100 | BAT02 |

| LOC01 | SKU02 | 50 | 50 | BAT03 |

Cycle Count Adjustment Records (Post task execution in Deferred mode):

After executing the tasks TASK01 and TASK02 simultaneously for SKU01 and SKU02 respectively. The system creates the following records (in deferred mode):

| Location | Task | Task type | SKU | Counted Quantity | Batch | Create User |

| LOC01 | TASK01 | TYPE01 | SKU01 | 75 | BAT01 | XXXX01 |

| LOC01 | TASK01 | TYPE01 | SKU01 | 75 | BAT02 | XXXX01 |

| LOC01 | TASK02 | TYPE02 | SKU02 | 150 | BAT03 | XXXX02 |

Location Inventory (Post task execution in Immediate mode):

The system updates the count details simultaneously in the ascending order of task execution.

| Location | SKU | Original Quantity | Current Quantity | Batch | Create User |

| LOC01 | SKU01 | 50 | 75 | BAT01 | XXXX01 |

| LOC01 | SKU01 | 100 | 75 | BAT02 | XXXX01 |

| LOC01 | SKU02 | 50 | 150 | BAT03 | XXXX02 |