Alert Management

Alerts are user workflow indicators. They are used to indicate situations where the optimization results fall outside of the business defined thresholds. Alert Management is where you will define which alerts are relevant to your business and the associated thresholds for each alert type.

-

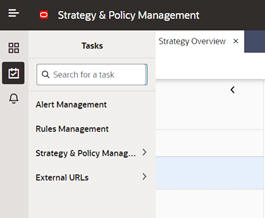

Open the Task menu.

Figure 11-4 Task Menu

-

Click Alert Management.

Inventory Alert Rules

Create or edit rule thresholds in any of the Rule Categories.

| Overstock | Alerts the inventory planner when a review day’s beginning of day inventory meets or exceeds the OUTL for that review day and/or Inventory units exceeds the specified threshold. This means that the inventory in the preceding period is more than enough to meet the demand of the prior, and the next review period. The inventory planner will review preceding stock levels, receipts, and forecast or actual sales. |

| Out of Stock |

Out of stock alerts are based on lost sales. This alert requires a demand forecast in order to calculate lost sales. Lost sales occur any day inventory plus receipts exceeds the forecasted demand. Note that retail value is always calculated as full retail value. |

| Low Stock |

Alerts the inventory planner to the days where inventory falls below acceptable thresholds of Days of Supply (DOS) and/or units. The DOS thresholds requires a demand forecast. The demand forecast is used to calculate average demand of the week. Then each day’s beginning inventory is divided by the average demand to determine if it falls below DOS threshold. A day that meets out of stock rules will not be alerted for Low Stock. Tip: to ignore DOS threshold set it to 0 and choose ‘OR’ Inventory is Less Than… |