14 Pre-Pack Optimization

Pre-pack configurations can be defined as follows.

Figure 14-1 Pre-Pack

Consider the following when optimizing pre-pack configurations.

Business Challenge

There are several interrelated and competing objectives. Smaller packs meet store-specific demand better, but create supply chain overheads and may not align with what the vendor can provide. Sub-optimal solutions often result in higher logistics costs, more stock outs, and lost revenue.

Balancing Tradeoffs

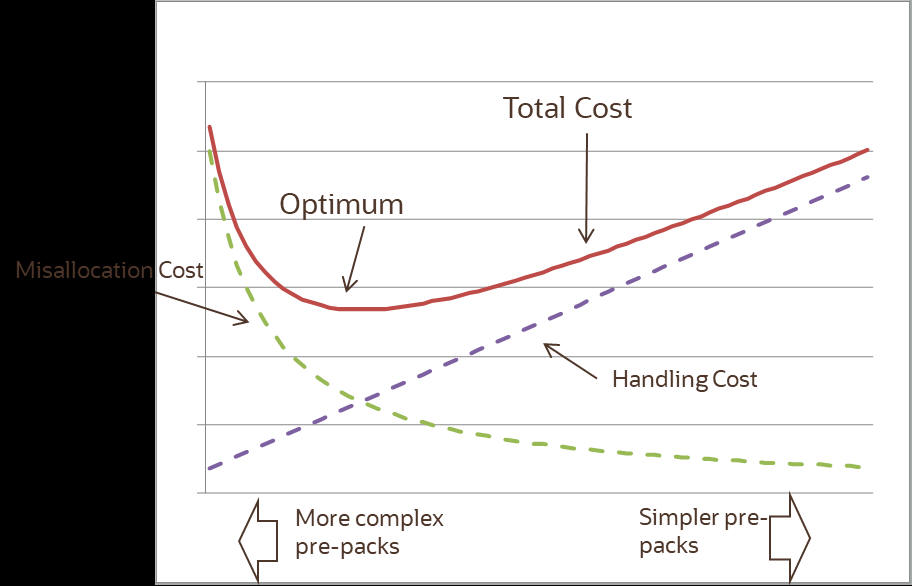

Tradeoffs can be made between smaller pre-packs (many pre-packs, lower misallocations, higher logistics costs) versus larger pre-packs (few pre-packs, higher misallocations, lower logistics costs).

Figure 14-2 Balancing Tradeoffs

Solution

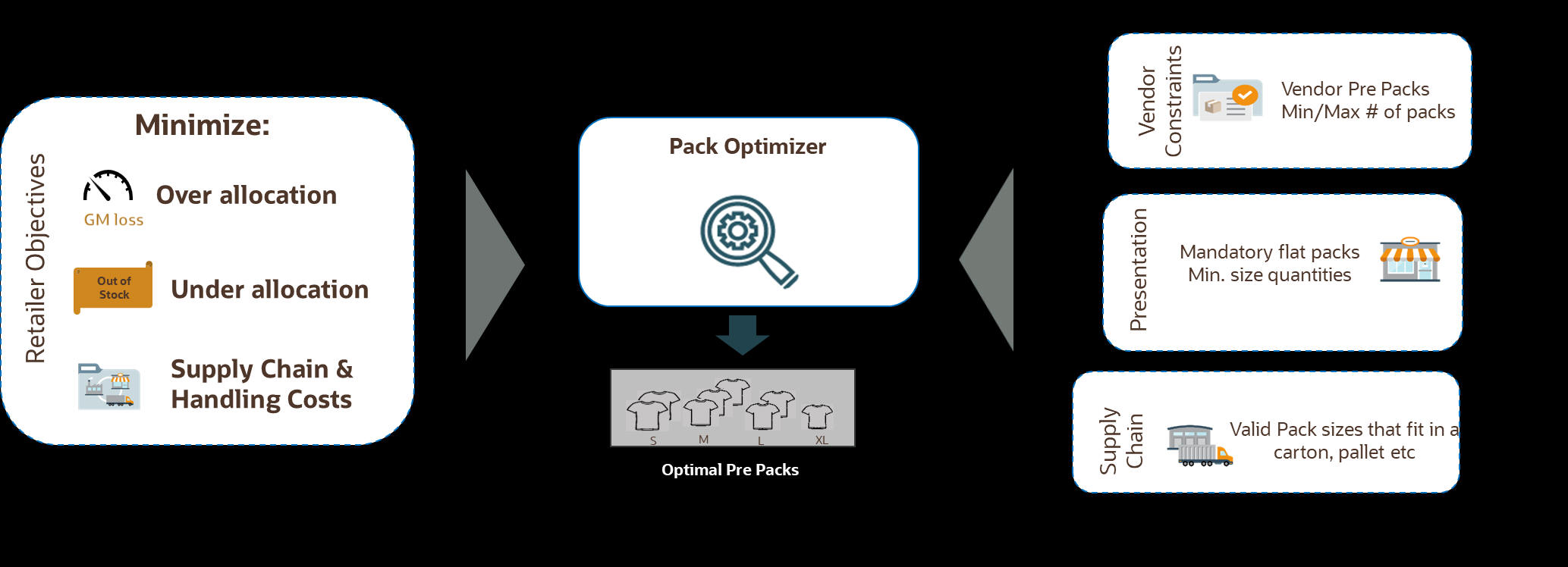

Consider the following recommendations:

- Recommend optimal pre-pack configurations that meet store-specific need while maximizing supply chain efficiencies.

- Consider vendor constraints, size min/max requirements, and so on, with rich scenario modeling support.

- Users learn business impact on changes to constraints.

Key Benefits

The benefits are as follows.

- Increase gross margin and revenue.

- Reduce shipping and handling costs.

- Improve stock rates and reduce overstocks.