10 Item Planning - Basics

Before the beginning of an item's lifecycle, Item Planning takes place. You have the option of planning full price sales by item, as well as the weekly receipt plan to support sales. The Item Plan can use the approved Assortment Plan as the starting point for the plan which can either come from an external Assortment Planning tool or the Assortment Strategy described in the prior chapter.

Item-Planning Basics handles the life cycle of Basic/Continuous items. In this workflow, you have the capability of planning for basics across multiple seasons in one workspace rather than having to plan and replan the same set of items in different workspaces, one for each season. Every fashion retailer has a mix of both basic and seasonal items. Basics are long lifecycle items that include white t-shirts, denims, socks, and so on, and are active lines throughout the year. Seasonal items are short lifecycle items such as specific winter wear or summer wear, active only during a particular season. You will have to log in to a different workspace for each season for short life cycle items. But, for long life cycle/basic items, Item-Planning Basics provides a single workspace to work across seasons for the chosen product hierarchy. If a subclass has a mix of both basic and seasonal items, you can review the aggregated plans of both basic and seasonal style colors in the Item-Planning workbook and make the required edits to meet Targets.

Typical Business Users

The typical business user who completes this task will be an Assortment Planner and Item Planner. The Planner will usually have completed the Assortment Planning process, and is now ready to plan the execution of that assortment plan for basic/continuous items in the Item Planning - Basics process.

Data Requirements

-

Approved location clusters

-

Location hierarchy

-

Product hierarchy

-

Calendar hierarchy

-

Sales Retail, Sales Unit, and Cost actuals

-

Curve Library

-

Item attributes and attribute values

-

Item images loaded by the Administrator (optional)

Create the Item Planning Basics Segment

When working in a segment, it is a common practice to keep the wizard selections for the segment size limited to what will be worked on, to facilitate navigation and increase UI responsiveness.

To create the Item Planning Basics segment:

-

Click the Assortment Services task in the Tasks menu. Then, click the Planning Services activity and then the Item Planning Basics task.

-

The dialog to create the new plan opens. Click Create New Plan.

-

Enter a descriptive Plan Label in the text field. Click Ok.

-

In Select Product, select one or multiple subclasses and click Next. Items having the attribute product type as basics alone will be visible in the wizard as this workbook is exclusively for basics.

-

In Select Calendar, select the time period for this assortment. Weeks belonging to Multiple Assortment Periods may be brought into the segment. The time period between the first week and the last week serves is the lifecycle of the item.

-

In Select Cluster Version, select the cluster you want to plan the basics in. If the cluster selected for planning basics is the same as the cluster assigned to the assortment period for the parent department, plans from IP Basics will match the plans in IP Pre-season and In-season workbooks.

If the cluster selected for planning basics is different than the cluster assigned to the assortment period of the parent department, plans created in IP Basics stored at the granular level of the store will get regrouped to the new cluster definitions of the IP Pre-season and In-season workbooks.

Note:

Assortment Details can vary by subclass. If multiple subcategories are selected, the details shown will be based on the first order subclass. When final plans are being reviewed in the IP seasonal workbook, if the cluster versions selected IP Basics and IP Seasonal workbooks are different, the plans from the Basics workbook will reaggregate based on the cluster definitions of the seasonal workbook.

Click Finish. The Item Planning Basics segment is built.

Item Planning Basics Process Steps

The high-level steps to complete this process:

-

Review targets from Assortment Strategy and MFP.

-

Plan Sales and Margin by item for basics.

-

Create a receipt and inventory plan by item for basics.

-

Reconcile to the targets.

-

Approve the Op and Cp version item plan for basics.

-

You can review these plans and aggregate basics and seasonal lines against department-level targets in the Item Planning Pre-season workbook.

If you override the approved plans for basics in the item-planning pre-season workbook, that will take priority over the approved basics plan. Whichever is the last committed and approved plan, will have precedence.

Step 1: Sales & Margin

The first step in the Item Planning Basics process is Sales & Margin. You can create a unit target from the CP of the Assortment Strategy, import it from an external Assortment Plan, or create a unit target using MFP, LY, or a user-entered number. The purpose of this step is to create unit targets for each item, to be used in the creation of the sales plan. This can be performed at the cluster level or higher. This step is also used to define parameters such as whether the item will be assorted in a particular cluster, start and end selling date overrides, and adjustments of full price sales.

The steps to complete this process:

-

Set item parameters.

-

Seed sales.

Tabs and Views in this Step:

Application Actions

Seed Sales

The Seed Sales Application Action populates an item's weekly sales based on the Sales Source selected.

Refresh Product Rollup

The Refresh Product Rollup Application Action creates dynamically nested three groups of alternate hierarchies based on three user-defined attribute selections for each selection. After running the Application Action, you may select the alternate product hierarchy to see rollups based on the selections.

Define Parameters Tab

The Define Parameters tab is used to plan Target Sales U, override start and end sell dates, seed sales based on a selected data source.

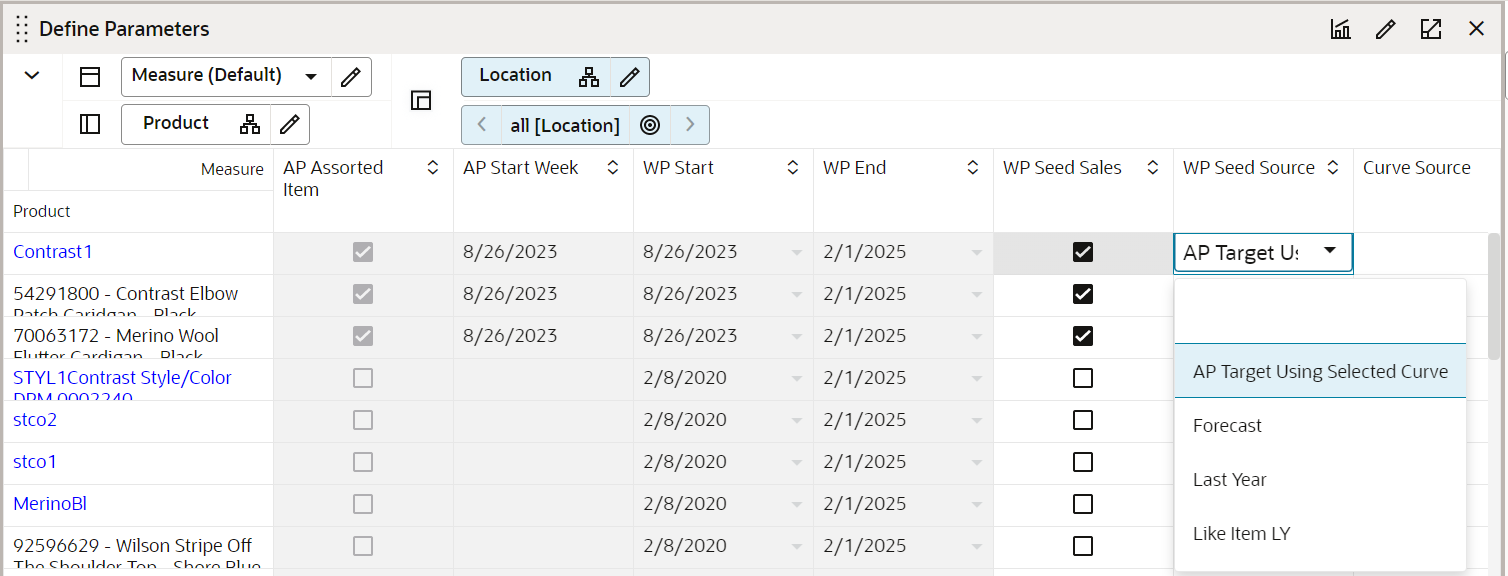

Define Parameters View

The Define Parameters view is used to assign a curve and seed sales. If all items within a subclass and all clusters will receive the same data, you can rollup to subclass and All Location in the product and location hierarchies, respectively.

The steps to complete this process:

-

Review the assorted items in the AP Tgt Assorted Item Boolean measure. Item Plans will be created for all assorted items. AP Tgt Assorted Item will be true if any weeks within this basic planning workbook contain weeks where the item is assorted in AP.

-

AP Tgt Sales U is the sum of all sales planned and approved from assortment periods. You can use the variance measure to populate the Tgt Sales U which is used to create the weekly sales using the selected curve. For item Planning Basics, this can be manually planned based on the number of seasons an item is being carried in. If AP Tgt Sales U gives N number of units per assortment period. If you are planning to carry this item in three assortment periods, you can populate the Tgt Sales U as 3*N, thereby planning enough quantity required to last the life. You can also plan units by editing the Target ROS measure which recalculates the Target Sales U.

-

Review the start and end selling weeks. The start and end selling week dates are based on the start and end week selected in the calendar wizard.

-

Optionally, override the start and end selling week dates. If the override start date is outside the workbook weeks, it will default the start week to the first week of the workbook. Similarly, if the override end date is outside the workbook weeks, it defaults to the end of workbook period.

-

In the WP Seed Sales measure, select the Boolean.

-

In the WP Seed Sales Source measure, select a data source to seed sales from:

-

Target Using Selected Curve: Sales TGT is defined in the Target Review step.

If this is the source selected, the WP Curve Source must also be defined.

-

Last Year: last year.

-

Like Item LY: like item last year.

-

Forecast: forecast.

-

IP CP: Item Plan Current Plan.

-

Like Item CP: Like Item Current Plan.

If this is the source selected, then WP Like Item and WP Like Item % must also be defined.

-

-

In the WP Curve Source measure, select the curve from which to seed sales.

Curves were set in the Assortment Maintenance segment and can be referenced in the Review Curve Library view.

-

If you want to assign a like item, in the WP Like Item measure, select the existing item to assign to the new item.

In the Like Item % measure, assign an adjustment ratio for the existing item sales to be copied to the new item.

-

A real time alert has been provided to alert the user if the target is selected, but the curve source and type are not set.

Additionally there is a real time alert if you select Seed Sales source of Like Item, but WP Like Item is not set.

Figure 10-1 Define Parameters View

Measure Table

Table 10-1 Define Parameters View Measures

| Label | Definition |

|---|---|

|

AP Assorted Item |

A Boolean flag measure that indicates when an item is carried in the Approved Assortment plan. The AP Assorted Item is True if any weeks within this Basic Planning workbook contain weeks where the item is assorted in AP. |

|

AP Assorted Item Count |

An integer measure used to indicate the total number of items carried. |

|

Tgt Sales U |

The Target Sales U planned by you. AP Tgt Sales U is the sum of all sales planned and approved cycle of the item. |

|

Tgt ROS |

The Target Rate Of Sale Planned by you. You can edit the Target ROS to change the Target Sales U. |

|

AP Start Week |

Read-only week based on the start week of the assortment period where the item is first assorted. |

|

Tgt Sales U Var AP Tgt % |

Variant measure that can be used to set Tgt Sales U in comparison with AG Tgt Sales U. |

|

Start Week |

The beginning of the item life cycle per the calendar wizard selection. If AP Start Week is populated, then it equals the AP Start Week. If not, it will default to the first week of the workbook built unless Selling Start Override is entered. |

|

End Week |

The ending of the item life cycle per the calendar wizard selection. It will default to the last week of the workbook built unless Selling End Override is entered. |

|

Wp Selling Start(Override) |

Overridden value of the beginning of item lifecycle. |

|

Wp Selling End(Override) |

Overridden value of end of item lifecycle. |

|

WP Seed Sales |

A Boolean flag measure which is required to be checked to create a weekly sales plan for assorted items. |

|

WP Seed Sales Source |

A drop-down list used to select the flow source for an item's sales. |

|

WP Curve Source |

A drop-down list used to select the curve source for an item's sales. |

|

WP Like Item |

An item used to populate the Sales R, U, and GM R of a new item being added to the assortment using an adjustment ratio. |

|

WP Like Item % |

Provides a facility to adjust a new item's Sales R, U, and GM R by using a percentage ratio to the sales of the like item. |

Measure Profile

Default Profile

The Default profile is used to assign item parameters before planning sales.

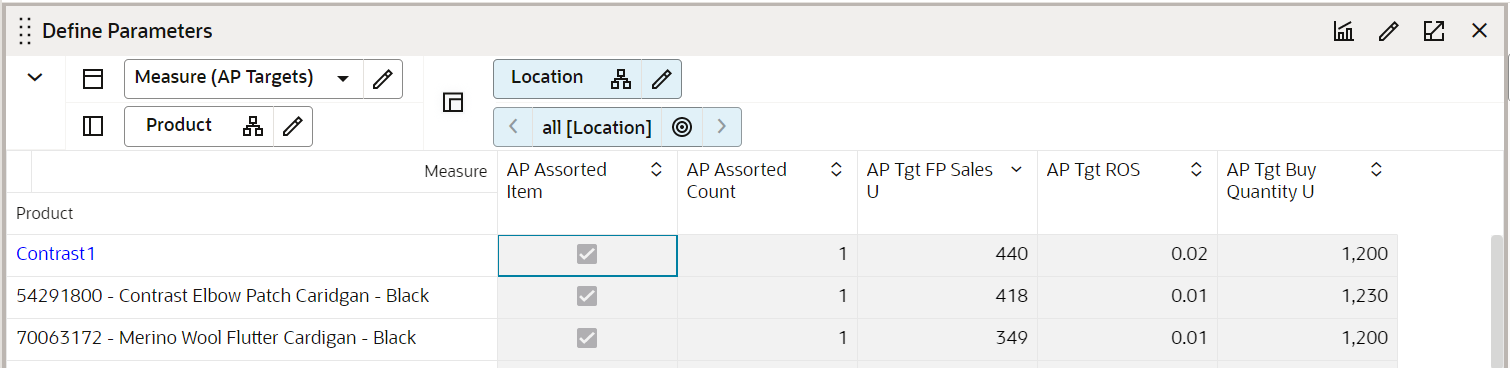

Figure 10-2 AP Targets Profile

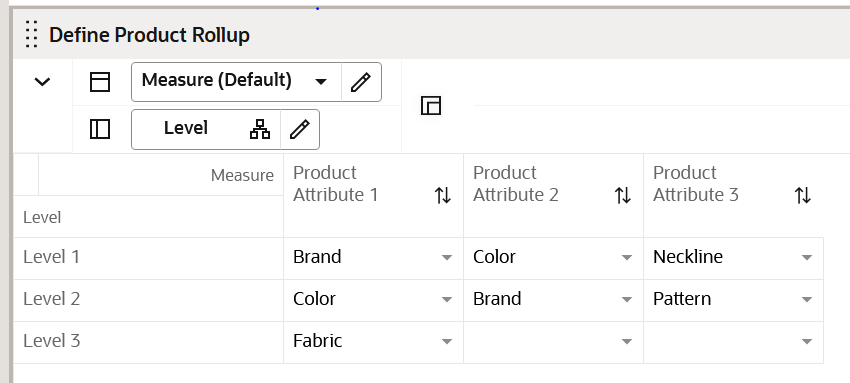

Define Product Rollup View

The Define Product Rollup view is used to select product attributes to view in an alternate hierarchy. This is available in the tab to display the item level. Nested product attribute rollup has been provided with three levels. You can set up to three different combinations for nested rollup with a maximum of three levels in each combination.

For example: as a first combination, you select Brand as a Level 1, Color as Level 2, and Fabric as Level 3 by clicking the list of attributes available in that category. This allows you to rollup your items by brand, then color inside each brand, and then by fabric inside each color.

This feature allows you to analyze and review the proposed assortment based on important attributes. You may select up to three attributes at a time for the dynamic rollup.

The steps to complete this process:

-

Select up to three dynamic product attributes from the drop-down list.

-

Run the Refresh Product Rollup Application Action.

-

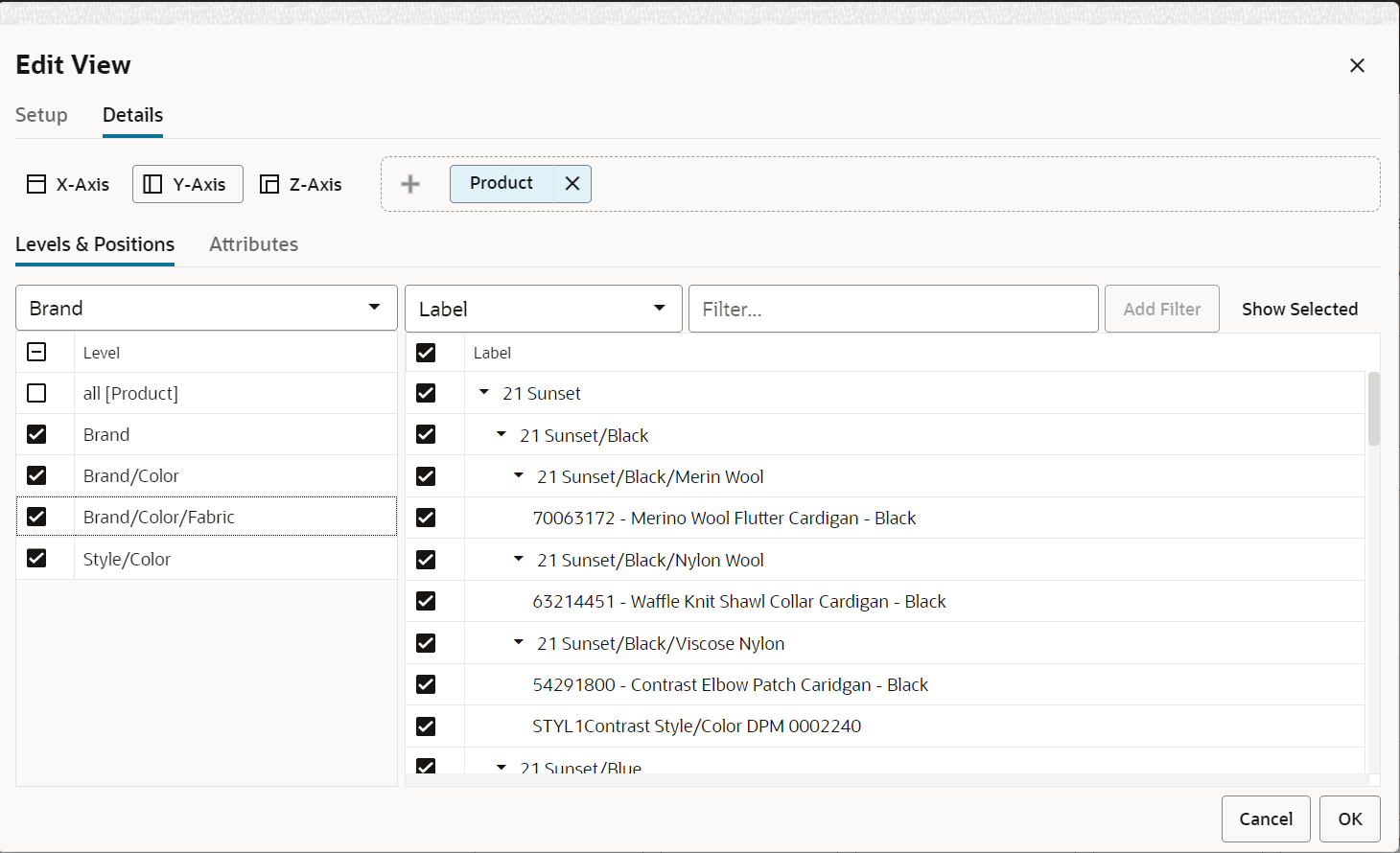

To view the product attribute:

-

In a view that displays the item level, click the Product Hierarchy tile.

-

Select the attribute (Attribute 1 or 2 or 3) that you would like to view in the nested dynamic rollup.

-

Click OK.

-

Figure 10-3 Define Product Rollup View

Figure 10-4 Edit View

Measure Table

Table 10-2 Define Product Rollup View Measure

| Label | Definition |

|---|---|

|

Product Attribute 1, 2, 3 |

Drop-down list to present product attributes for a dynamic product hierarchy rollup. |

Measure Profile

Default Profile

The Default profile is used to select dynamic product attributes. You can view up to three levels to review and work on Plans rolled up to multiple attributes. Using the nested dynamic product rollup feature, you can group plans for three different attributes. If you are working on a class, Level 1 is brand, Level 2 is color, and Level 3 is fabric, you can review and analyze plans for all brands of a class, then across all colors inside each brand, and then across every fabric for each color.

Application Action

Refresh Product Rollup

The Refresh Product Rollup Application Action creates dynamically updated alternate hierarchies based on user-defined attribute selections. After running the Application Action, you may select the alternate product hierarchy to see rollups based on the attribute selections.

Integration with Assortment Planning

The Basic Sales Reg+Promo U is available in the Recommend Assortment and Plan Buy Quantity worksheets as a read-only measure to show the approved CP Sales Reg and Promo units from the Item Planning - Basics template. This allows you to see basic planned sales in case these basic items already have sales planned farther out in the future, so it serves as a reference for you to select the basic items with the sales plan and use for planning the buy quantity.

Integration with Item Planning

The WP and approved version of data from the Item Planning - Basics workbook should reflect in the pre-season and in-season templates. It will load/refresh the corresponding week's Sales plan from the Basics workbook to the Item Planning templates. It also works vice versa if you plan in the Item Planning templates for the basic items and commit/approve should reflect the change in the Basics workbook.

If the basic items are planned farther out in the planning horizon than the assortment periods, there will be a real-time alert in pre-season and in-season workbooks to notify you that you should assort/add the basic item with the approved plan. In the pre-season workbook, this real-time alert will be reflected in the WP Assorted Item flag. In the in-season workbook, this real-time alert is reflected in Keep/Add/Drop. This will allow you to make sure they include the basic items already planned in the planning horizon using the new basic planning template.

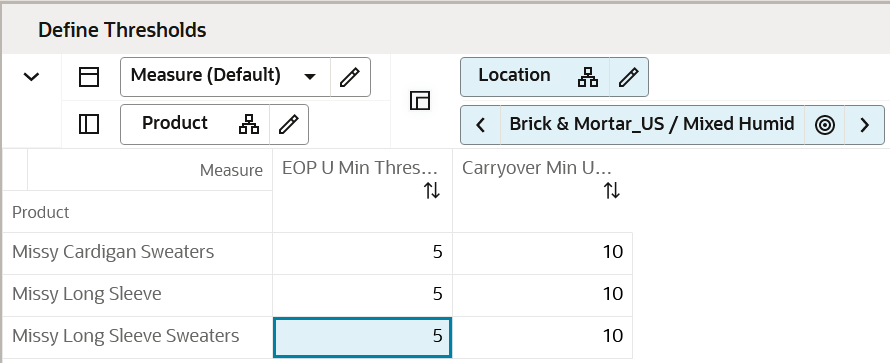

Define Thresholds View

This view focuses on removing special, one-off buys to optimize the history used for target option calculations. You can create the parameters around historical data used to calculate the Target Number of options.

The step to complete this process:

-

Define thresholds for minimum Sales Units, Receipts Units, and Carryover Units.

Figure 10-5 Define Thresholds View

Measure Table

Table 10-3 Define Thresholds View Measures

| Label | Definition |

|---|---|

|

EOP U Min Threshold |

Minimum EOP Units threshold to consider the options into the Rate of Sales Calculation that is defined at subclass or higher levels. |

|

Carryover Min Units Threshold |

Minimum on hand Units threshold to consider the options as Carryover status. |

Measure Profile

Default Profile

This profile is used to access the view which focuses on defining the thresholds.

Review Curve Source View

The Review Curve Source view shows the normalized Forecast, Last Year, and MFP Sales Curve % for the calendar duration of the workbook at the subclass/cluster intersection. The seed sales custom menu is executed with the curve source selecting either the absolute or relative curve. If you select Absolute as the curve type, Absolute will take the curve source's respective selling weeks of the item and normalize it. If you select the curve type Relative, it will take the curve of the entire workbook duration and shrink it to fit the item's selling periods.

The Review Curve Source view is a reference-only view used to review curves that were set up in Curve Maintenance. The curves can be applied to the sales, to intelligently spread sales over time, which is later used for planning receipt flows. For more information about the different types of curves and their functionality, see Curve Maintenance.

The step to complete this process:

-

Review the sales percent to totals for each curve, as necessary.

Figure 10-6 Review Curve Library View

Measure Table

Table 10-4 Review Curve Source View Measure

| Label | Definition |

|---|---|

|

Fcst Sales Curve U % |

Used to display the weekly sales percent to total of Forecast Sales curve. |

|

Ly Sales Curve U % |

Used to display the weekly sales percent to total of Last year Sales curve. |

|

MFP Sales Curve U% |

Used to display the weekly sales percent to total of MFP Sales curve. |

Measure Profile

Default Profile

The Default profile is used to view each curve.

Review Normalized Curve View

The Review Normalized Curve view is a read-only curve showing the applied sales percent to the total of the selected curve at the style-color level. This view allows you to analyze weekly sales percentages at the item level for a chosen cluster.

Measure Table

Table 10-5 Review Normalized Curve View Measure

| Label | Definition |

|---|---|

|

Wp Normalized Curve U % |

Used to display the weekly sales percent to total of the applied sales curve. |

Measure Profile

Default Profile

The Default profile is used to view the curve for each style-color.

Sales and Margin Tab

The Sales and Margin tab is used to plan Regular and Promotional Sales by item and cluster.

Plan Sales & Margin View

The Plan Sales and Margin view is used to plan Regular and Promotional Sales by item, week, and location cluster.

Running the Seed Sales Application Action creates the following logic for each Assorted Basic Item:

-

Source Sales Units are spread to week based on the source selected.

-

Units are multiplied by the Base Unit Price and Base Unit Cost to get Retail and Cost.

Base Unit Price and Cost are interfaced from a source system for existing items and entered by you for placeholder items in the Item Administration segment.

The steps to complete this process:

-

Review and adjust each item/week/cluster Regular Sales:

-

It is a best practice to seed sales before planning the sales buckets so that there is a demand curve in Reg Sales from which to begin your plan.

-

If there is no seeding and no prior data entered, then planning WP Sales will spread proportionally (since there is no demand curve the data will spread evenly) to Reg Sales.

If that is not the desired behavior, plan Reg Sales before planning Sales, so that a demand curve is in place before planning WP Sales.

-

-

Review and adjust Sales after having planned Regular Sales, if necessary.

User-Defined Exceptions are a helpful way to identify exceptions that need to be manually adjusted. For detailed information on these capabilities, see the Oracle Retail Predictive Application Server Cloud Edition User Guide.

-

Review AUC and GM measures to ensure the financial viability of the plan.

Figure 10-7 Plan Sales & Margin View

Measure Interactions

The following logic is used when planning different types of sales:

-

WP Sales are the aggregation of WP Sales Reg and WP Sales Promo.

-

Updates to WP Sales will update WP Reg Sales and WP Promo proportionally.

-

Updates to WP Sales Reg R will hold AUR and recalculate Units.

Measure Table

Table 10-6 Plan Sales & Margin View Measures

| Label | Definition |

|---|---|

|

Selling Weeks |

A Boolean flag measure used to indicate the week the item begins selling in the assortment. |

|

WP Sales Reg R, U, AUR |

Regular Sales Retail, Units, and Average Unit Retail. |

|

WP ROS |

Working Plan Rate of Sales. |

|

WP Sales GM R, GM R % |

Sales Gross Margin value and Gross Margin percent for an item. |

|

Fcst Sales U |

Forecasted Sales Units from IPOCS-Demand Forecasting. |

|

Base Unit Price R |

An item's retail value and can be different by location. |

|

WP Sales R, U, C, AUR, AUC |

Working Plan Sales Retail, Units, Cost, Average Unit Retail, and Average Unit Cost. |

Measure Profiles

Figure 10-8 Plan Sales & Margin View: Measure Profiles

Default Profile

The Default profile is used to Regular and Promotional sales by item and cluster.

Measure Table

Table 10-7 Plan Sales & Margin View with Returns/Net Sales Measures

| Label | Definition |

|---|---|

|

Fcst Sales U |

Forecasted Sales Units from IPOCS-Demand Forecasting. |

|

Customer Returns R, R %, U, U%, AUR, C, AUC |

Customer Returns Retail, Retail percent of WP Sales R, Units, Units percent of WP Sales U, Average Unit Retail, Cost and Average Unit Cost |

|

Net Sales R, U, AUR, C, AUC, GM R, GM % |

Net Sales = Sales - Customer Returns Net Sales Retail, Units, Average Unit Retail, Cost, Average Unit Cost, Gross Margin value and Gross Margin percent. |

|

WP Sales C, AUC |

Working Plan Sales Cost and Average Unit Cost for an item. |

Last Year Profile

The Last Year profile is used to review last year Regular and Promotional data compared to the working plan.

Original Plan Profile

The Original Plan profile is used to review the most recently approved Item Plan Original Plan (OP) Regular and Promotional data compared to the working plan.

Current Plan Profile

The Current Plan profile is used to review the most recently approved Item Plan Current Plan (CP) Regular and Promotional data compared to the working plan.

Reconcile to MFP View

The Reconcile to MFP view in Item planning Basics is used to compare the working plan of the item plan to the approved MFP Current Plan (MFP Tgt) for each subclass and cluster.

The steps to complete this process:

-

Review WP Sales var MFP Tgt % measures to identify variances that are outside of acceptable parameters.

Review Sales R, Sales U, Sales C, and GM variances to ensure that all of the financials meet targets or are within the targets.

-

Make adjustments to the sales and the receipt plans to be within an acceptable variance.

-

If a subclass has a mix of both Basic and Seasonal lines, Basics are planned here. MFP Targets serve as a reminder of the Target. Final Reconciliation happens in the Item Planning Pre-season workbook after aggregating item plans for both Basics and Seasonal lines

Repeat this process for each subclass and cluster in the assortment.

Note that if a Location Plan is not available, the MFP CP view displays the MFP Current Plan by subclass spread to Location using last year's location sales' proportionality. If a Location Plan is available, the MFP CP view displays the MFP Current Plan by subclass spread to Location using the Location Plan CP sales' proportionality.

Figure 10-9 Reconcile to MFP View

Measure Table

Table 10-8 Reconcile to MFP View Measures

| Label | Definition |

|---|---|

|

MFP Sales R, U, AUR, C, AUC, GM R, GMR% |

MFP Sales Retail, Units, Average Unit Retail, Cost, Average Unit Cost, Gross Margin value, Gross Margin percent. |

|

WP Sales R, U, AUR, C,AUC, GM R, GM R% |

IP Working Plan Retail, Units, Average Unit Retail, Cost, Average Unit Cost, Gross Margin value, Gross Margin percent. |

|

WP Sales Reg+Promo R, U, AUR |

IP Working Plan Full Price Retail, Units, Average Unit Retail. |

Step 2: Receipts & Inventory

The third step in the Item Planning Basic process is Receipts & Inventory for basic lines. This step is used to define parameters such as BOS inventory, initial buys, lead time, presentation minimums, and safety stock, among other parameters.

The steps to complete this process:

-

Set inventory parameters.

-

Seed receipts.

-

Adjust receipts and inventory based on the sales plan.

Tabs and Views in this Step:

Application Actions

Flow Receipts

The Flow Receipts Application Action populates a weekly receipt plan based on the parameters Order Frequency, Pres Mins, and Safety Stock Weeks.

Round Receipts

The Round Receipts Application Action uses the inputs of WP Pack Size U and WP Min Order Quantity to round receipts up to match these parameters.

Receipts & Inventory Tab

The Receipts & Inventory tab is used to set inventory parameters to flow receipts and to adjust weekly sales and receipts to create an inventory plan for reconciliation and approval.

Define Parameters View

The Define Parameters view is used to assign inventory and receipt parameters to flow receipts. Based on the parameters, the system will calculate the optimal receipt flow to support the sales plan.

The steps to complete this process:

-

In the WP Flow Receipts measure, select the Boolean.

-

If an item is a carryover item, it will inherit its projected EOP for the Start Sell week and populate the BOP.

-

For the new item, plan the BOP for the first week Item Lifecycle, visible in the Receipts and Inventory tab.

-

Entering a BOS would not be necessary in this scenario.

Planning the BOS will populate the first week BOP of the Assortment Period, visible in the Receipts and Inventory tab.

Plan two out of the three measures to calculate the third value.

-

In the WP Initial Buy U, C, and AUC measures, enter the initial buy quantities for each item.

Plan two out of the three measures to calculate the third value.

-

In the WP Initial Receipt Lead Time measure, enter the number of weeks before the Start Sell week that receipts should be received.

-

In the WP Lead Time (Days) measure, enter the number of days it takes for the product to arrive from your vendor/supplier to the warehouse or store.

This measure is used to generate the Immediate Need real time alert in the In-season Planning segment, letting you know that your EOP is less than your Safety Stock.

-

In the WP Order Frequency (Weeks) measure, enter how often receipts will arrive.

For example, entering 1 means that receipts arrive every week, and 2 means that receipts arrive every other week.

-

In the WP Presentation Min U measure, enter the minimum amount of inventory on the sales floor per store.

This is used only in calculating the initial buy and can be thought of as a fixture fill.

-

In the Safety Stock (Weeks) measure, enter the number of weeks of sales that the safety stock should cover.

Use this measure to use future weeks of sales to generate a dynamic safety stock recommendation.

It is recommended to use Safety Stock U or Safety Stock (Weeks)to generate a recommended initial buy.

-

Click Calculate.

-

Review the WP Initial Buy U var Recommended % to compare your set initial buy to the system calculated initial buy that is based on the entered parameters.

The WP Recommended Initial Buy is based on BOS, Order Frequency, Presentation Minimums, Safety Stock Weeks, and the Sales plan.

-

Make adjustments to the initial buy quantities to ensure that items are not over or under-inventoried.

-

In the Tgt WOS measure, enter a target Weeks of Supply.

This is used in the In-season segment to compare the Tgt WOS with the WP WOS.

-

In the WP Pack Size U measure, enter how many items come in a pack.

This measure is used in conjunction with the Round Receipt Application Action to round receipts up to the pack size entered.

For example, if your pack size is 10 and your receipts are 88, it will round up to 90 to meet the pack size.

-

In the WP Min Order Quantity measure, enter a minimum order quantity.

This measure is used in conjunction with the Round Receipt Application Action to round receipts up to the minimum order quantity entered.

For example, if your minimum order quantity is 100 and your receipts are 88, it will round up to 100.

-

Run the Flow Receipts Application Action to create a weekly receipt flow based on the parameters and the Sales plan.

-

Run the Round Receipts Application Action to round receipts using the Pack Size and/or Min Order Quantity measure inputs.

Review your WP EOP, WP WOS and WP Sell Thru % after running the Round Receipts Application Action to ensure that you are not over-inventoried due to rounding up.

Figure 10-10 Define Parameters View

Measure Table

Table 10-9 Define Parameters View Measures

| Label | Definition |

|---|---|

|

WP Flow Receipts |

A Boolean flag measure that is required to be checked to calculate receipt quantity and flow based on set parameters and the sales plan. |

|

WP Initial Buy U, C, AUC |

The planned initial buy Units, Cost, and Average Unit Retail. |

|

WP Initial Buy U var Recommended % |

The variance between the planner input Initial Buy and the system-recommended Initial Buy. |

|

WP Recommended Initial Buy U, AUC |

The system calculated recommended initial buy Units and Average Unit Cost based on Order Frequency, Presentation Minimums, Safety Stock Weeks, and the Sales plan. |

|

WP Initial Receipt Lead Time |

The number of weeks before the start sell week that the receipts should arrive. You can select the number of weeks from a drop-down list, with the maximum value being set in the Assortment Period Maintenance segment. |

|

WP Lead Time (Days) |

The number of days it takes for the product to arrive from your vendor/supplier to the warehouse or store. This measure is used to generate the Immediate Need real time alert in the In-season Planning segment, letting you know that your EOP is less than your Safety Stock. |

|

WP Order Frequency (Weeks) |

How often, in weeks, receipts arrive. |

|

WP Presentation Min U |

The minimum amount of inventory on the sales floor per store. This is used only in calculating the initial buy and can be thought of as a fixture fill. |

|

WP Safety Stock (Weeks) |

The number of future weeks of sales that additional units should be maintained to mitigate the risk of stockouts, based on future sales weeks. It is used for the initial buy as well as for subsequent receipt drops. |

|

Tgt WOS |

The planner entered targeted WOS by item/cluster, used in the Overage Real Time Alert. |

|

WP Pack Size U |

The number of units that come in a pack, used to round up receipts. |

|

WP Min Order Quantity |

The minimum order quantity, used to round up receipts. |

Measure Profile

Default Profile

The Default profile is used to assign receipt parameters before flowing receipts.

Application Actions

Flow Receipts

The Flow Receipts Application Action populates a weekly receipt plan based on the parameters Order Frequency, Pres Mins, and Safety Stock Weeks.

Round Receipts

The Round Receipts Application Action uses the inputs of WP Pack Size U and WP Min Order Quantity to round receipts up to match these parameters.

Plan Receipts & Inventory View

The Plan Receipts & Inventory view is used by you to adjust net sales if necessary and adjust the receipt plan to meet sales needs based on business knowledge or constraints.

The steps to complete this process:

-

Review the WP Net Sales U and make adjustments if necessary.

-

Review the WP Receipts U and make adjustments to quantities or delivery weeks based on business knowledge.

-

Review the WP EOP U to ensure there are no over or under-stock issues.

If the receipt plan does not support the sales plan, a Real Time Alert will be activated to alert action is needed.

Adjust the sales or the receipt plan to resolve the Real Time Alert.

-

Review the WP WOS to view the calculated Weeks of Supply based on the sales and receipt plan.

The WP WOS metric represents the number of future calendar positions that the current stock will cover. For example, If your calendar is aggregated to month, then WP WOS represents the future number of months that the stock will cover, if the calendar is aggregated to quarter, then it represents the number of quarters that the stock will cover.

The WP WOS Weeks metric represents the inventory available to cover the future weeks at the week level irrespective of the calendar level selected.

For each week, WOS is calculated as the number of future weeks of sales covered by the current period's EOP U.

-

Review the WP Sell Thru % as a reference value to see how fast inventory is projected to sell through.

For each week, Sell Thru % is calculated as Net Sales Units / (BOP U + Receipts U).

-

Review the Cost measures.

Repeat this process for each item and cluster in the assortment.

Note that you can use Product Attributes to rollup your items by attributes. For example, this can be used to view inventory levels by attributes that are important to the category, to make sure that receipts are invested for important attributes.

Figure 10-11 Plan Receipts & Inventory View

Measure Table

Table 10-10 Plan Receipts & Inventory View Measures

| Label | Definition |

|---|---|

|

Selling Weeks |

A Boolean flag measure used to indicate the week the item begins selling in the assortment. |

|

WP BOP U, C, AUC |

The calculated Beginning of Period Units, Cost, and Average Unit Cost. |

|

Net Sales U, C, AUC |

Net Sales Units, Cost, and Average Unit Cost. |

|

Receipts U, C, AUC |

Receipts Units, Cost, and Average Unit Cost. |

|

EOP C, AUC |

The calculated End of Period Cost and Average Unit. |

|

WP WOS |

The number of future weeks of sales that will be covered by the current week's EOP U for the calendar level selected. |

|

WP WOS Weeks |

The number of future weeks of sales that will be covered by the current week's EOP U at the week level |

|

Sell Thru % |

The percent of inventory that will be sold during a period, calculated as Net Sales Units / (BOP U + Receipts U). |

Real Time Alerts

Inventory Stock Thresholds

Alerts you that EOP Units are negative. Adjust the sales or the receipt plan to resolve the alert. The alert is activated when EOP falls lower than the Pres Min, and Safety Stock Weeks measures.

Measure Profiles

Default Profile

The Default profile is used to plan weekly receipts to cover the sales plan based on EOP inventory objectives.

Last Year Profile

The Last Year profile is used to compare the WP weekly receipts and inventory levels to last year values.

Initial Buy Profile

The Initial Buy profile is used to plan initial buy quantities for the first drop.

Original Plan Profile

The Original Plan profile is used to compare the WP weekly receipts and inventory levels to an approved Original Plan.

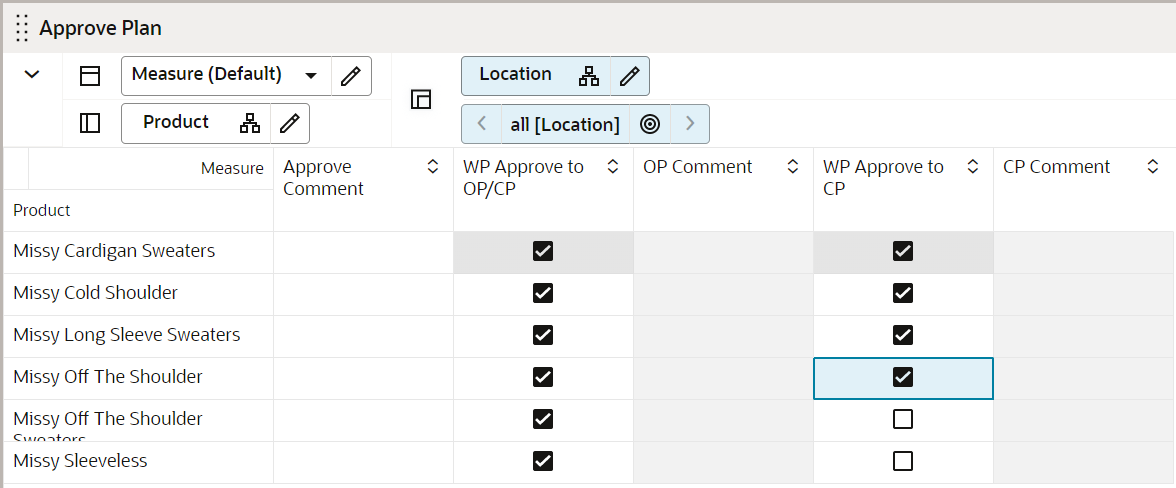

Step 3: Approve Plan

The final step in the Item Planning process is the Approve Plan. This step approves the item plans that you have created, analyzed, and reviewed for accuracy.

The output of this step is an approved Item Plan Original Plan and Current Plan.

The step to complete this process:

-

Approve the item plan.

Figure 10-12 Approve Plan Step

Before Starting this Step:

-

Thoroughly analyze and review the item plans by cluster to ensure they meet the financial goals of the category.

After Completing this Step:

-

Begin Item Planning pre-season for seasonal items.

Tab and View in this Step:

Application Action

Approve Plan

The Approve Plan Application Action copies data from the Working Plan (WP) to the Original Plan (OP) and the Current Plan (CP).

Approve Plan Tab

This tab is used to approve the plan.

Approve Plan View

The steps to complete this process:

-

In the WP Approve to OP/CP measure, select the Boolean flag for the subcategories and clusters that should be approved.

If all subcategories and clusters should be approved at once, rollup to All Product and All Location and select the Approve to OP measure at that level.

-

In the WP Comment measure, enter approval comments.

The WP Approval Comments will be copied to the OP Approval Comments and concatenated with the approver's ID, for future reference in this view.

-

Run the Approve Plan Application Action.

Note that the Approve Plan Application Action creates the OP and CP versions of the plan.

Figure 10-13 Approve Plan View

Measure Table

Table 10-11 Approve Plan View Measures

| Label | Definition |

|---|---|

|

WP Approve to OP/CP |

CP Boolean flag measure that when selected, approves the Working Plan Item Plan to the Original Plan and the Current Plan. |

|

WP Comments |

Comments entered here will be copied to the OP Approval Comments and concatenated with the approver's ID, for future reference in this view. |

|

OP Comments |

Original Plan comments used as a reference. |

Measure Profile

Default Profile

The Default profile is used to approve the Item Plan to the OP and CP versions.

Application Action

Approve Plan

The Approve Plan Application Action copies data from the Working Plan (WP) to the Original Plan (OP) and Current Plan (CP).