D Appendix: IPOCS-Lifecycle Allocation and Replenishment Exceptions & Alerts

This appendix provides the complete list of alerts defined for the GA version of IPOCS-Lifecycle Allocation and Replenishment. The list of alerts includes alerts for the IPOCS-Lifecycle Allocation and Replenishment set up validation and alerts for IPOCS-Lifecycle Allocation and Replenishment data validation (for example, generated orders).

The exception management framework available in RPASCE works on different levels. Starting with the dashboard component, the exception profiles allow you to view the hit count for every exception. Once in the workspace, you can use the workspace alerts to navigate to the product/location combination (or product/location/weeks) that have been flagged. Every dashboard exception has a workspace alert counterpart. The calculation expressions are not identical, because the dashboard exceptions are at the production/location intersection, while the workspace alerts also have the time dimension.

Finally, every defined exception can be used in the approval logic. Order approval can be controlled by the alerts:

-

Manual

The system-generated orders are not automatically approved. Order values must be manually approved by accessing and possibly amending values in the A & R Admin workspace.

-

Automatic

The system-generated orders are automatically approved as is (no blocking alerts triggered).

-

By exception

This list contains the exceptions that were configured for use in the replenishment approval process. They should match the dashboard exceptions and workspace alerts.

Setup Exceptions

The Setup exceptions are used to alert you for potential set up issues in the supply chain network. The following are all set up exceptions available in IPOCS-Lifecycle Allocation and Replenishment.

BOD Exception Count

This exception indicates what ranged products and locations are currently with no BODs assigned.

Lifecycle Phase Exception Count

This exception indicates what ranged products and locations are currently with no lifecycle phase defined.

Planning Calendar Exception Count

This exception indicates what ranged products and locations are currently with no planning calendar assigned.

Replenishment Exceptions

Use the replenishment exceptions to alert you for potential issues in the replenishment parameters set up and for specific exceptions that might need to be looked at, for example, a replenishment watch list.

During the batch, IPOCS-Lifecycle Allocation and Replenishment calculates the system proposed order after which the alerts are calculated. Once calculated the alerts are used by IPOCS-Lifecycle Allocation and Replenishment to let the system know if the proposed orders can be approved or not. If for specific item/location combinationss, there are critical alerts (alerts classified as critical are within the Review Alerts workspace) then IPOCS-Lifecycle Allocation and Replenishment does not auto-approve the orders and you must review them before approving manually within the system. Following are all the replenishment exceptions available in IPOCS-Lifecycle Allocation and Replenishment.

Future Promotions

This exception indicates what ranged item/location combinations have promotions flagged in the future. You can then review the replenishment and take the necessary action in preparation for the promotion (for example, increment the replenishment values before the start of the promotion).

Replenishment Watch-List

This exception indicates what items/location combination are in the replenishment watch list. This alert allows you to keep track of replenishment for specific item/location combinations. This exception is not automatically calculated by IPOCS-Lifecycle Allocation and Replenishment. You are able to include or exclude item/location combinations from the replenishment watch list within the Review Alerts workspace. IPOCS-Lifecycle Allocation and Replenishment uses those values to calculate this exception.

Lifecycle Mat to EOL

This exception indicates what ranged item/location combinations have a lifecycle phase change from Maturity to EOL. The alert is valid for 7 days so you can review item/location combinations that changed from Lifecycle Mat to EOL for the last 7 days.

No Replenishment

This exception indicates the ranged item/location combinations with valid lifecycles that have an unconstrained need but have no system, approved, or exported plan.

No Replenishment Method

This exception indicates the ranged item/location combinations with valid lifecycles and no replenishment method (parameters) assigned to them. The replenishment parameters need to be reviewed for these item/location combinations.

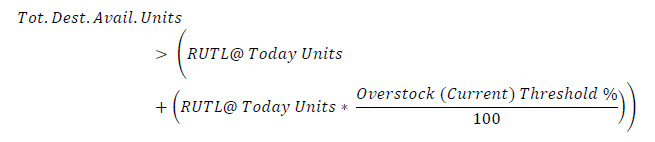

Overstock (current)

This exception indicates the ranged item/location combinations that have surplus quantity based on the next run order (point-in-time replenishment). The surplus quantity is only considered if it is higher than a defined threshold, which can be specified in units or percentages. The calculation is as follows (the assumption to apply the calculations is that there is a surplus. Otherwise, the alert is not triggered):

Figure D-1 Units Calculation

Figure D-2 Percentage Calculation

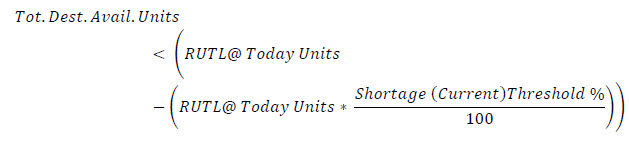

Shortage (current)

This exception indicates the ranged item/location combinations that have a deficit quantity based on the next execution order (point-in-time replenishment). The deficit quantity is only considered if it is less than a defined threshold, which can be specified in units or percentages. The calculation is as follows (the assumption to apply the calculations is that there is a deficit. Otherwise, the alert is not triggered):

Figure D-3 Units Calculation

Figure D-4 Percentage Calculation

Forecast Watch-List

This exception indicates what item/location combinations are in the forecast watch list. This alert allows you to keep track of specific item/location combinations forecast. This exception is not automatically calculated by IPOCS-Lifecycle Allocation and Replenishment. You can include or exclude item/location combinations from the forecast watch list within the Review Alerts workspace. IPOCS-Lifecycle Allocation and Replenishment uses those values to calculate this exception.

New SKU

This exception indicates the new items that were introduced into IPOCS-Lifecycle Allocation and Replenishment. The way IPOCS-Lifecycle Allocation and Replenishment identifies the new items is by using the assortment start date. If the assortment start date is in the future, then the item/location combinations triggers this alert. When the system reaches the assortment start date, then the item/location combinations no longer trigger the alert.

Recent Item Launch

This exception keeps track of ranged item/location combinations that were recently assorted. To trigger the alert, IPOCS-Lifecycle Allocation and Replenishment uses the assortment start date plus a Recent Item Launch X Dur (weeks) parameter. If the assortment start date plus the X weeks defined in the parameter did not reach the system date, then the item/location combinations trigger the alert.