F Appendix: PO Allocation Setup and Validation

This appendix provides details to setup and validate PO Allocation.

Perform the following steps to validate PO allocation.

-

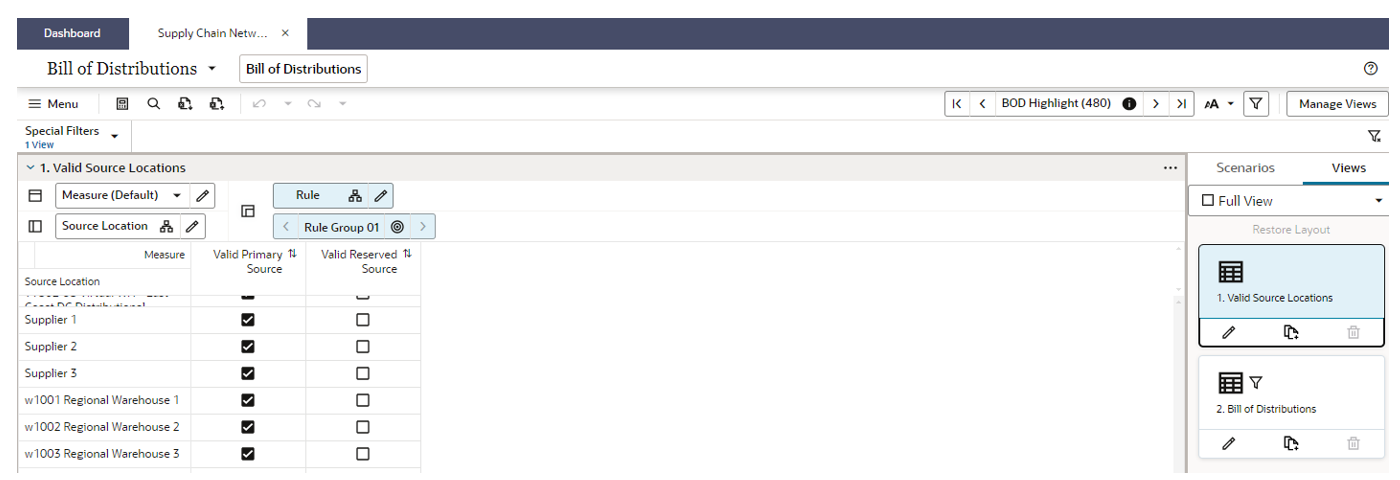

Make sure the warehouse or distribution center is selected as a Valid Primary Source in the Supply Chain Network workspace.

Figure F-1 Select Valid Primary Sources

-

Define the Bill of Distribution by setting the BOD Primary Source and BOD Lead Time.

Figure F-2 Define the Bill of Distribution

-

Define the Planning Calendar and Lifecycle Calendar.

-

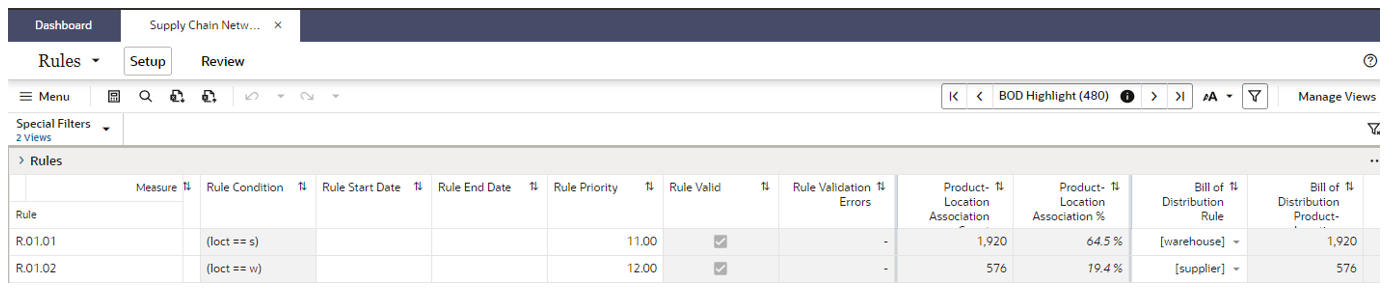

Define the Supply Chain Network rules.

Figure F-3 Define the Supply Chain Network Rules

-

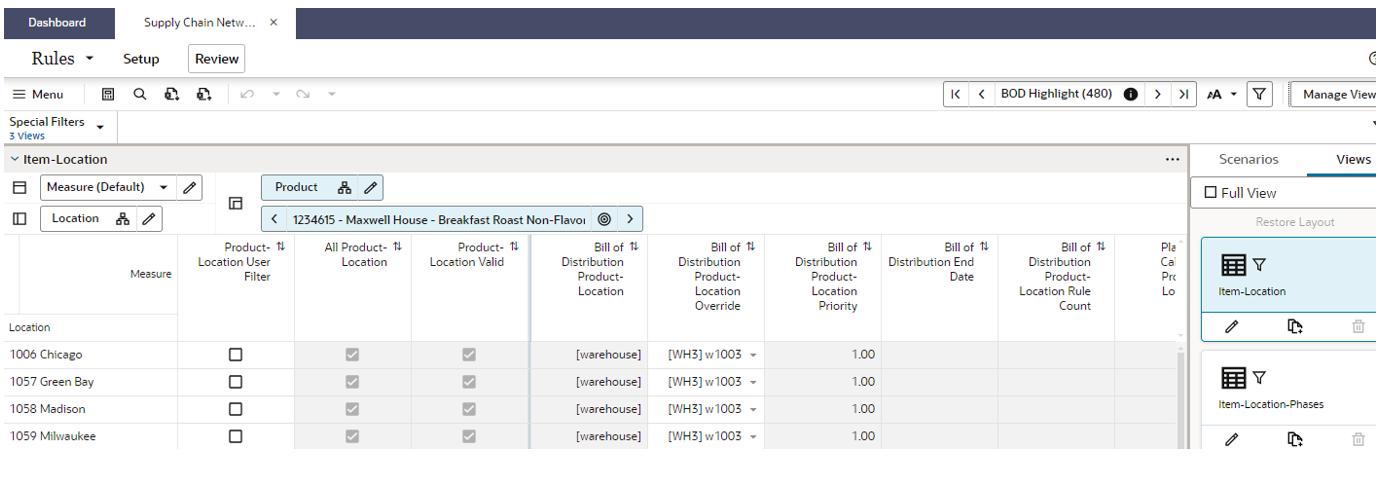

You can override the rules setup in the previous step at the item/store.

Figure F-4 Override the Rules Setup

-

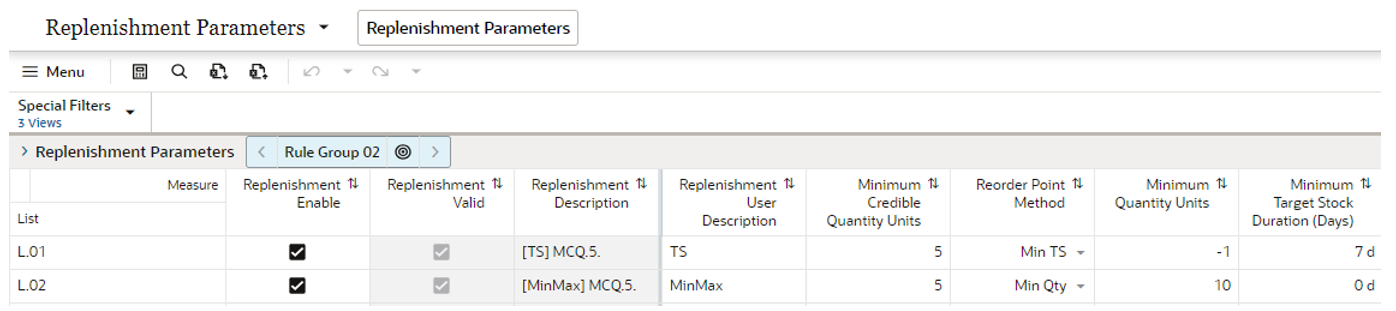

Setup Replenishment Parameters in the Replenishment Parameters workspace.

Figure F-5 Setup Replenishment Parameters

-

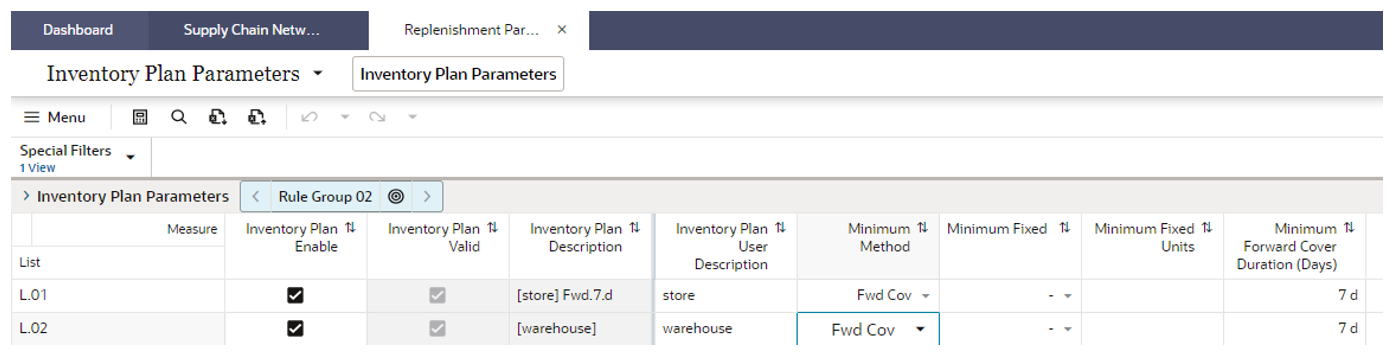

Setup the Inventory Plan Parameters. This only needed for Inventory Plan and Warehouse replenishment.

Figure F-6 Setup Inventory Plan Parameters

-

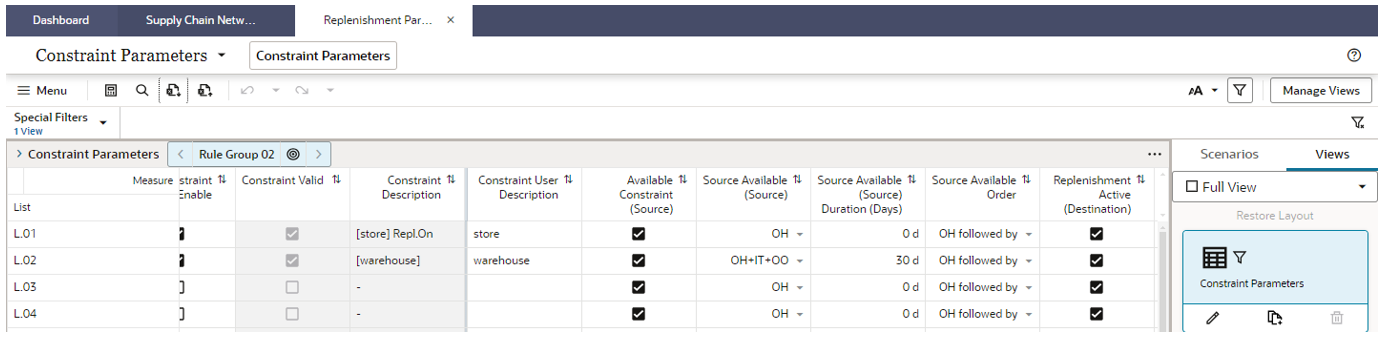

Setup the Constraint Parameters. For PO Allocation make sure that the Source Available includes On-Order (OO). By default, On-hand (OH) is consumed first and then followed by On-Order. You can use the Allocation Order measure to change the default behavior; whether OH is followed by OO (default) or OO is followed by OH. Make sure to specify the Source Duration days at the Warehouse. This measure indicates the On-Orders that will be considered for allocation that are arriving at the Warehouse within this duration.

Figure F-7 Setup the Constraint Parameters

-

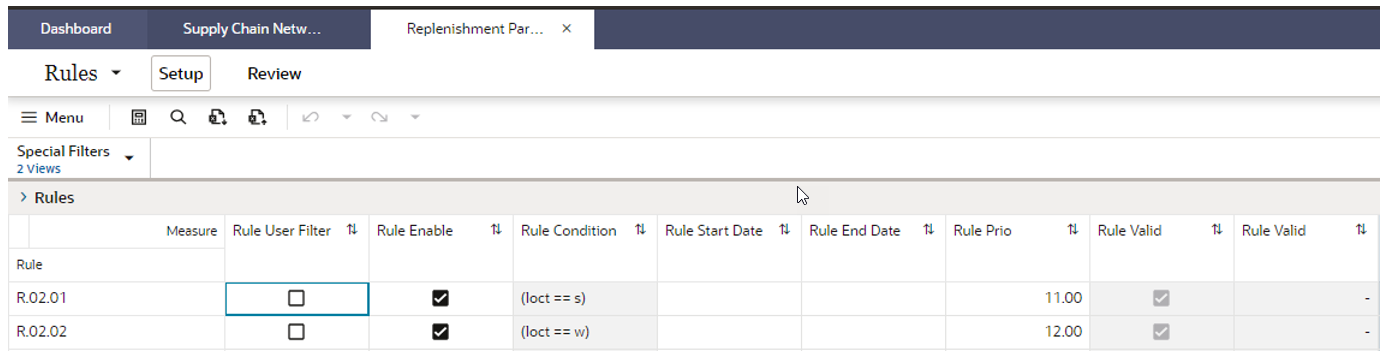

Setup the Replenishment Parameter rules.

Figure F-8 Setup the Replenishment Parameter Rules

-

Make sure the item/stores have forecast because this will generate the need at the destination store.

-

Run the LAR batch.

-

Based on the need at the destination store, the PO’s will be allocated.

-

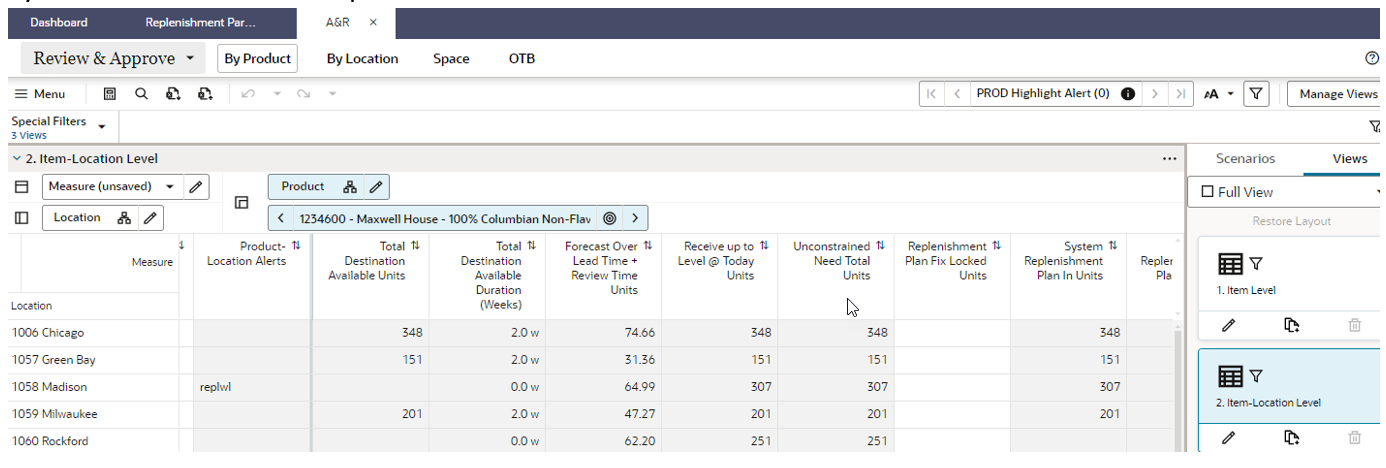

Set the System Plan in the A and R workspace.

Figure F-9 Set the System Plan

-

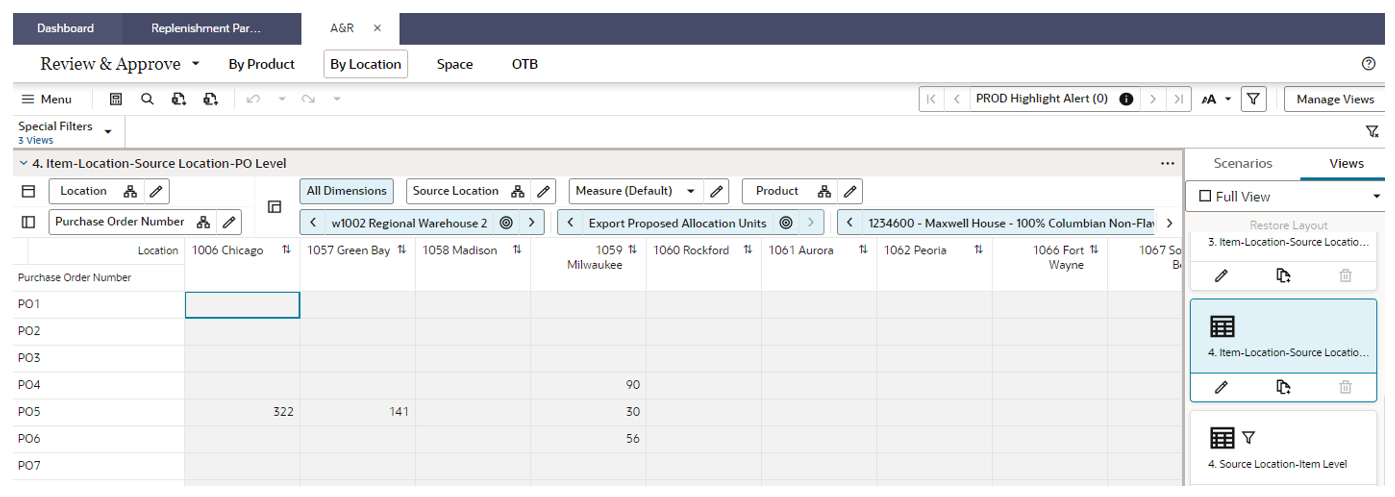

View the Exported PO allocation.

Figure F-10 Exported PO Allocation