8 Moving Stock

This chapter contains the following topics:

-

Section 8.3, "Recording an Intra-Depot Stock Movement for a Kit"

-

Section 8.4, "Recording a Gain or Loss on an Intra-Depot Stock Movement"

-

Section 8.6, "Calculating Volume from Weighbridge Information"

8.1 Understanding Stock Movement

For a fill, decant, or repack, if you must record a gain or loss, you need to perform a conversion at the item level for the volume of each unit of the packaged product. You also need to set up a conversion factor of .0000001 per one empty package so that the system can convert each subfile line to the unit of measure of the bulk gain or loss item. Set this up at the system level for each empty package unit of measure. For example, set up .0000001 liter (LT) per 1.0 item.

Packaged items contain bulk stock at standard temperature, not ambient temperature, because the temperature of the product in the package cannot be determined.

Record a rebrand when product is mislabeled as it arrives at the depot and needs to be renamed. Alternatively, you might want to record a rebrand if the same product is sold under different names to different customers for marketing reasons. One way to handle this circumstance is to designate one product to be a parent item and the other to be a component of a kit.

The system requires that all volume and weight units of measure have conversions to kilograms (kg) and cubic meters (M3) for calculation purposes.

Additionally, you can account for gains or losses that might occur during a stock movement and record stock movements involving kit items.

When you record stock movements, the system updates these tables:

-

Bulk Product Transaction File (F41511) if moving a bulk item.

-

Gain/Loss Transactions File (F41512) if the system creates a gain or loss.

-

Location Detail Information (F4602) if warehouse control is active for the branch/plant.

Note:

You can record stock movements only to the current accounting period.

Six processing groups exist. They are defined by the processing options that determine how each of the stock movements is processed.

8.2 Recording Intra-Depot Stock Movements

This section provides an overview of intra-depot stock movements and discusses how to:

-

Set processing options for General Stock Movements (P415101).

-

Record intra-depot stock movements.

8.2.1 Understanding Intra-Depot Stock Movements

Record stock movements whenever you must account for stock that can no longer be found in the location or container to which it was previously assigned.

For each type of intra-depot stock movement, you complete the same basic steps to record the movement. The version that you use and the information that you need to enter vary, depending on the type of movement that you are recording. The stock movement types are defined by the processing type and the processing option settings for the General Stock Movements program (P415101).

When you enter an intra-depot stock movement, you can select an option to display the Journal Entries program to review the accounting information for the transaction.

You cannot change or delete the transactions in the system because transactions create inventory and general ledger records in the system. If you enter a transaction in error, you must:

-

Locate the transaction.

-

Reverse the entry.

-

Enter information on a blank line to correct the error.

When you reverse a transaction, post the batch created by the reversal to update the general ledger. For a reversal, the program stores the general ledger date from the original transaction as the historical date.

8.2.2 Forms Used to Record Intra-Depot Stock Movements

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| General Stock Movements | W415101B | Stock Movements (G415011), Bulk Stock Adjustments, Consumed In Operations-Own Use, Tank to Tank Transfer, Repacking, Rebrand, Regrade, Decanting, Filling, or Simple Blending.

Click Add on the Work With General Stock Transactions form. |

Record intra-depot stock movements. |

| Work With Item Availability | W41202A | On the General Stock Movements form, select an item and then select Availability from the Row menu. | Review item availability. |

8.2.3 Setting Processing Options for General Stock Movements (P415101)

Processing options enable you to specify the default processing for programs and reports.

8.2.3.1 Process Type

- Processing Type

-

Enter the processing type. Values are:

Blank: No processing type

1:: Adjustments

2: Consumed in Op

3: Tank to Tank Transfer

4: Repack, Decant, Fill

5: Rebrand, Regrade

6: Blending

8.2.3.2 Default Values

- 1. Document Type

-

Enter a document type. A document type is a code from UDC 00/DT that identifies the origin and purpose of the transaction.

- 2. Reason Code

-

Specify the purpose for a transaction from UDC 42/RC.

- 3. Gain/Loss Location

-

Specify a gain/loss location.

8.2.3.3 Inventory

- 1. Transfers greater than quantity available

-

Specify whether to allow a transfer that is greater than the quantity available. Values are:

Blank: No transfers

1: Allow transfers

- 2. From and To quantities

-

Specify whether the From and To quantities must balance to zero. Values are:

Blank: Quantities do not need to balance.

1: Quantities must balance to zero.

- 3. From and To lines

-

Specify whether the From and To lines must have the same packaged items. Values are:

Blank: Lines do not have the same packaged items.

1: Lines have the same packaged items.

- 4. Update the Item History file

-

Specify whether the system updates the Item History table. Values are:

Blank: No update

1: Update the file

8.2.3.4 Lot Options

- 1. Lot expiration date assignment

-

Specify how to assign the lot expiration date. Values are:

Blank: No lot expiration date assignment.

1: Assign Manually.

2: Newest From Expiration.

3: Oldest From Expiration.

4: Trans (transaction) date + shelf life.

- 2. Transfers from held lots

-

Specify whether the system allows transfers from held lots. Values are:

Blank: No transfers

1: Allows transfers

8.2.3.5 G/L Info

- 1. Summarize journal entries by account within document

-

Specify whether the system summarizes journal entries by account within the document. Values are:

Blank: Does not summarize

1: Summarizes

- 2. Account number information

-

Specify whether the system allows entry of account number information. Values are:

Blank: Does not allow entry

1: Allows entry

8.2.3.6 Agreements

- Agreement assignment

-

Specify how the system assigns an agreement. Values are:

Blank: No agreement assignment

1: Assign agreement if only one is found.

2: Always display all applicable agreements. If you enter a 2, the system finds multiple agreements and displays a check mark in the row header that is located in the detail area and in the Agreements Exists column. You must use a Row exit to select an agreement.

3: Assign agreement with the earliest expiration date.

8.2.4 Recording Intra-Depot Stock Movements

Access the General Stock Movements form.

- F T (From line or To line)

-

Enter a code that indicates whether a line in a transaction is a From line or a To line. This field enables you to combine multiple existing products or locations into a single product or location. For example, you can create three From lines and one To line. You can also split one existing product or location into several new products or locations. For example, you can create one From line and two To lines. The information contained in a From transaction line is always existing item location information.

Depending on the type of intra-depot stock movement, the transaction can be a From, a To, or both. A From transaction reduces the inventory in that location. A To transaction increases the inventory in that location.

Processing Groups 1 and 2 can have either a From or a To transaction, but not both.

Processing Groups 3, 4, 5, and 6 must have both a From and a To transaction.

- Location

-

Specify the storage location from which goods will be moved.

- Ambient Volume

-

Enter the volume as measured for density and temperature before conversion. You can enter the ambient quantity or let the system automatically calculate it.

- Standard Volume

-

Enter the volume after it has been converted to a standard base. Conversions are made according to published standard routines for density, gravity, and temperature.

Normally, you leave the Standard Volume field blank and allow the system to calculate it. However, if you enter the volume and unit of measure, the system accepts it as valid and performs no calculation.

- Weight Result

-

Enter the weight of the product at standard temperature. The system calculates the weight by multiplying the volume by the density and applying an air correction, if necessary (all at the base temperature).

- Unit Cost

-

Enter the amount per unit, derived by dividing the total cost by the unit quantity.

A processing option controls whether this field appears. If you leave this field blank, the system uses the cost setup for the item in the Cost Ledger field, based on the costing method for the item branch being used.

- Extended Cost/Price

-

Enter the extended cost or price value of an inventory transaction for an inventory item.

- U F (update control flag)

-

Specify whether to update the general ledger for commingled product.

Typically, you update the general ledger for the product that belongs to the company's inventory, not the product that belongs to another owner. Values are:

Y or 1: A journal entry is written.

N or 0: A journal entry is not written.

- Agreement Number

-

Enter a unique number that the company assigns to identify a particular agreement. You might want to assign some significance to the agreement number (for example, an agreement type code, location, year, and so forth). An agreement might have multiple supplements to record changes.

- Supp No (supplement number)

-

Enter the supplement number that identifies any changes or addendum to agreements that occur over time or by item. It can also indicate individual agreements that are tied to a master agreement. The system allows up to 999 different supplements per base agreement number.

- Lot Number (Release 9.1 Update)

-

Enter a number that identifies a lot. A lot is a group of items with similar characteristics.

A processing option controls whether the Lot field appears. Complete the lot information only if you are using lot processing.

Note:

A tank can contain only one lot number at a time. If you attempt to complete a transaction with a lot number other than the current lot number, the system displays an error message - ”Lot Number Conflict”.You can change the current lot number through one of the following transactions:

-

Blending

-

Repacking

-

Filling

-

Decanting

-

Rebanding

-

- Country of Origin (Release 9.1 Update)

-

Enter a code (00/CN) that identifies the country in which an item originates.

- Expiration Date

-

Enter the date on which a lot of items expires.

The system automatically enters this date if you have specified the shelf life days for the item on the Item Master form or the Item Branch/Plant Information form.

The system calculates the expiration date by adding the number of shelf life days to the date that you receive the item.

You can commit inventory based on the lot expiration date for items. You select how the system commits inventory for an item on the Item Master form or the Item Branch/Plant Information form.

- Lot Stat Code (lost status code)

-

Enter a user-defined code (41/L) that indicates the status of the lot. If you leave this field blank, it indicates that the lot is approved. All other codes indicate that the lot is on hold.

You can assign a different status code to each location in which a lot resides on Item/Location Information form or Location Lot Status Change form.

- Reason Code

-

Enter a user-defined code (42/RC) that explains the purpose for a transaction. For example, you can indicate the reason that you are returning items.

8.3 Recording an Intra-Depot Stock Movement for a Kit

This section provides an overview of intra-depot stock movements for a kit and discusses how to record an intra-depot stock movement for a kit.

8.3.1 Understanding Intra-Depot Stock Movements for a Kit

You might need to record a stock movement that involves a kit item, such as when entering a simple blend transaction. When you enter a transaction that includes a kit item in the movement, you first copy a bill of material to obtain the parent item information for the kit. Then, you enter detail information for the stock movement.

|

Note: If you specify detail information before you copy a bill of materials, the system deletes the information. You must enter it again. |

8.3.2 Forms Used to Record an Intra-Depot Stock Movement for a Kit

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| General Stock Movements | W415101B

Stock Movements (G415011), Bulk Stock Adjustments, Consumed In Operations-Own Use, Tank to Tank Transfer, Repacking, Rebrand, Regrade, Decanting, Filling, or Simple Blending |

Stock Movements (G415011), Bulk Stock Adjustments, Consumed In Operations-Own Use, Tank to Tank Transfer, Repacking, Rebrand, Regrade, Decanting, Filling, or Simple Blending

Click Add on the Work With General Stock Transactions form. |

Enter general stock movement information.

After copying a bill of material for a kit, finish recording the intra-depot stock movement. |

| Copy Bill of Materials | W415101D | From the Form menu on the General Stock Movements form, select Copy BOM. | Copy a bill of material for a kit. |

8.3.3 Recording an Intra-Depot Stock Movement for a Kit

Access the General Stock Movements form.

8.4 Recording a Gain or Loss on an Intra-Depot Stock Movement

This section provides an overview of intra-depot stock movement gains and losses and discusses how to record a gain or loss on an intra-depot stock movement.

8.4.1 Understanding Intra-Depot Stock Movement Gains and Losses

When product is moved from one location, tank, or container to another, a change in volume can occur due to spillage, leakage, evaporation, and temperature changes. You can account for these gains or losses when recording the from and to movements of the product.

You can specify gains or losses for these stock movements:

-

Tank-to-tank transfer

-

Repack

-

Decant

-

Fill

You use the processing options for P415101 to control how gains or losses are recorded:

-

Set the Gain/Loss Location processing option on the Defaults tab to specify a default gain/loss location.

-

Set the From and To quantities processing option on the Inventory tab to ensure that the From, To, and Gain/Loss quantities equal zero.

-

Set a processing option to require that the From quantity, the To quantity, and the gain/loss quantity balance.

The system calculates gains and losses as follows:

-

The sum of all To transactions (converted to a standard unit of measure and temperature) minus the sum of all From transactions (converted to a standard unit of measure and temperature) equals the gain or loss.

-

You record gains and losses to a logical location instead of a physical location to prevent the gains and losses from adjusting actual inventory.

Because no item or location record exists, searching by location will not display the inventory for the location.

-

The program converts all products within a transaction to the primary unit of measure associated with the gain or loss bulk product.

If the unit of measure conversion is not set up by item, the system uses the standard unit of measure conversions.

8.4.1.1 Example: Recording Loss

This diagram illustrates the transfer of 1000 LT from Tank A to Tank B. After the transfer, Tank B reports receiving only 995 liters. To accurately account for the transfer, you record a 5-liter loss to the logical location:

Figure 8-2 Example of bulk liquid transfer

Description of "Figure 8-2 Example of bulk liquid transfer"

You do not record a 5-liter loss to Tank A because 1000 liters actually left Tank A. Likewise, you do not record a gain of 5 liters to Tank B because only 995 liters actually entered Tank B.

8.4.2 Form Used to Record a Gain or Loss on an Intra-Depot Stock Movement

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| General Stock Movements | W415101B | Stock Movements (G415011), Bulk Stock Adjustments, Consumed In Operations-Own Use, Tank to Tank Transfer, Repacking, Rebrand, Regrade, Decanting, Filling, or Simple Blending

Click Add on the Work With General Stock Transactions form. |

Record an intra-depot stock movement that includes both a From and a To transaction on two lines.

The system calculates the gain/loss quantity and displays it in the primary unit of measure. Enter the item number and location for gain/loss information. |

8.4.3 Recording a Gain or Loss on an Intra-Depot Stock Movement

Access the General Stock Movements form.

- Item Number

-

Enter a number that the system assigns to an item. It can be in short, long, or third item number format.

Identifies the product to be adjusted. If this is a stock movement for a bulk item, the system uses the product number from the Current Product field on the Tank Master form as the default value when you enter the transaction.

The gain/loss product must be a bulk product. An entry in this field is required for repack, decant, or fill transactions, but not for tank-to-tank transfer.

- Location

-

Enter the storage location from which goods will be moved.

8.5 Calculating Volume from Dip Readings

This section provides an overview of volume calculations from dip readings and discusses how to:

-

Calculate volume for a stock movement.

-

Calculate volume for a simultaneous movement.

8.5.1 Understanding Volume Calculations from Dip Readings

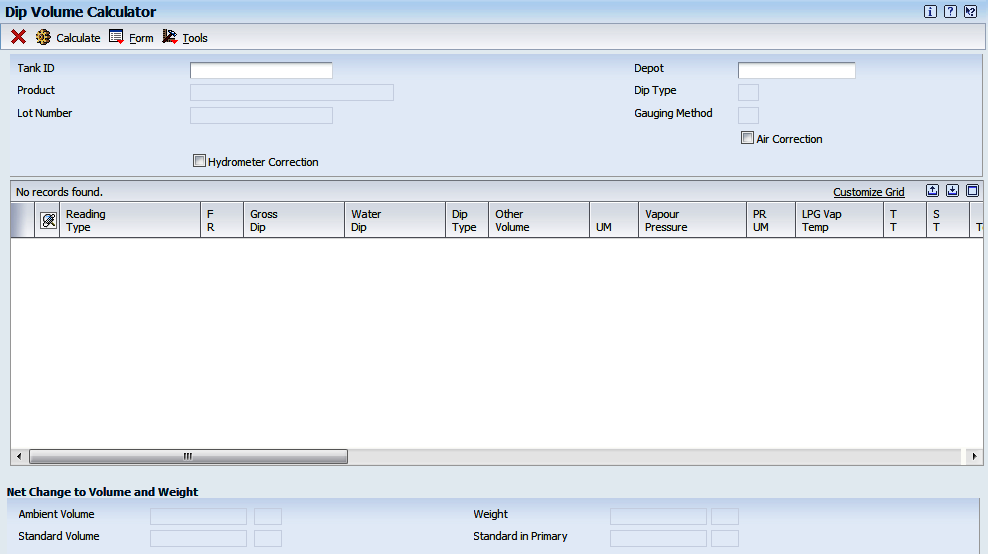

You use the Dip Volume Calculator form to calculate volume for stock movements when you obtain dip readings based on tank strapping information.

Typically, a dip reading is taken before and after a movement occurs. After you enter these readings, the program calculates:

-

Ambient volume.

-

Standard volume.

-

Primary stock accounting unit (PSAU) volume.

-

Weight.

It also calculates the difference between the before and after quantities. An after dip that is lower than the before dip is considered a discharge from the tank. The reverse is considered a receipt of product.

When you enter before and after dip readings, the program uses the tank strapping information to calculate the ambient volume for each dip reading. The system takes the tank type and the dip type into account, and applies the floating roof displacement correction, if necessary.

You can calculate volume from dip readings while recording stock movements or receiving products, or as a single step from the Bulk Stock Management menu. When you calculate volume as a single step, the program acts as a calculation tool only. It does not store the values. When you use the Dip Volume Calculator program while recording stock movements or receiving products, the calculations are stored in the Bulk Product Transactions File table (F41511).

You can access the Dip Volume Calculator form directly from the Bulk Stock Management menu (G41501) or by selecting Dip/Meter from the row menu on any stock movement form on the Stock Movements menu (G415011). Alternatively, from the Purchase Order Receipts form, select Bulk, and then Dip Volume Calc from the Row menu.

For liquefied petroleum gas (LPG) products, the Dip Volume Calculator program:

-

Corrects the liquid volume to 15° Celsius using the LPG tables.

-

Calculates liquid mass (weight).

-

Determines the presence of inert gas that affects vapor density calculation.

-

Derives vapor density.

-

Calculates vapor mass (weight).

-

Calculates vapor volume.

-

Calculates volume as: total volume = liquid volume + vapor volume.

-

Calculates weight as: total weight = liquid weight + vapor weight.

-

Calculates the liquid volume from the strapping tables.

8.5.1.1 Volume Calculation for a Stock Movement

To calculate volume for a stock movement, use information from the tank strapping table and enter the dip readings. You must enter the dip readings in the same units that are set up in the system's tank strapping table: centimeters, feet or inches, and fractions. The calculation program will not convert dip readings.

You might not need to take tank strappings. Alternatively, you can enter the ambient volume directly in the Other Volume field. The program will convert ambient volume to standard volume. If you directly enter ambient volume, you must also enter the before and after dip readings as zero.

If the dip type is E for an electronic gauge reading, the system considers the gross dip readings that you enter as volumes, not strappings, and does not make strapping conversions. It only makes the conversion to standard volume. The program uses the unit of measure from the default tank strappings. You can enter electronic gauge readings in ambient volume, standard volume, or weight.

If you record an electronic reading in weight, enter the weight in the Gross Dip field. The Gauging Method in the Tank Master must be specified as W (weight). The program uses the entry as a weight (where the unit of measure is the weight unit of measure specified in the Item Master) and enters the appropriate amounts in the Bulk Item ledger.

If you are moving a large quantity of product, you can enter the Before reading now and record the After reading at a later time.

If you use an LPG item and if vapor calculations are active, the program processes the entry as if the entry has no vapor. If you enter a total weight (liquid + vapor), the program cannot determine which portion is liquid and which is vapor, so vapor calculations are invalid, regardless of whether vapor calculations are active.

When you calculate volume for a stock movement, the system performs volume calculations and retrieves values for these fields:

-

Ambient Volume

-

Volume - Standard

-

Weight Result

-

Quantity - Primary Stock Accounting Unit

8.5.1.2 Volume Calculation for a Simultaneous Movement

You can calculate volume for a simultaneous movement, such as simultaneously receiving and withdrawing product from the same tank.

When you calculate volume from dip readings, you can also record the meter readings from a withdrawal of product. When you enter these readings, the system adds the quantity that you withdraw back into the quantity calculated from the dip readings. A message appears to indicate that a simultaneous withdrawal occurred.

You cannot calculate volume for a simultaneous movement if you select Dip Volume Calculator from the Bulk Stock Management menu.

You must record any gain or loss associated with this type of transaction to the outturn gain/loss.

See Recording a Gain or Loss on an Intra-Depot Stock Movement.

8.5.2 Forms Used to Calculate Volume from Dip Readings

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| General Stock Movements | W415101B | Stock Movements (G415011), Select either: Bulk Stock Adjustments, Consumed In Operations-Own Use, Tank to Tank Transfer, Repacking, Rebrand, Regrade, Decanting, Filling, or Simple Blending

Click Add on the Work With General Stock Transactions form. |

Enter general stock movement information. |

| Dip Volume Calculator | W415102A | On the General Stock Movements form, select Dip/Meters from the Row menu. | Calculate volume for a stock movement. |

| Discharge Meter Readings | W415102B | On the Dip Volume Calculator form, select Meter Readings from the Form menu. | Calculate volume for a simultaneous movement. |

8.5.3 Calculating Volume for a Stock Movement

Access the Dip Volume Calculator form.

- Tank ID

-

Enter a code that identifies a tank.

- Depot

-

Enter an alphanumeric code that identifies a separate entity within a business.

- Lot Number (Release 9.1 Update)

-

The system displays the lot number associated with the tank.

- Gross Dip

-

Enter a number that represents the total dip reading of a tank. (Net volume = gross dip volume − water dip volume + other volumes.)

You can enter a number for a single dip or multiple dip reading. Enter dip readings in increments consistent with the strapping units on the tank strapping table (for example, centimeters or feet/inches/fractions).

For U.S. increments, Branch/Plant Constants controls the delimiter that indicates the separator between the units of measure (for example, between feet, inches, and fractions). Therefore, if you used / as the delimiter, for:

15 feet 10 1/2 inches, enter 15/10/8

15 feet, enter 15//

6 feet 4 13/16 inches, enter 6/4/13

12 feet and 5/16 inches, enter 12//5

Fractions are shown in sixteenths of an inch.

- Water Dip

-

Enter a number that represents the total dip reading of water in the tank.

Net volume = gross dip volume − water dip volume + other volumes.

This can be a single dip or a multiple dip reading.

You might need to review the strapping information for the tank. You can select an option to access the Tank Strapping Table program. In addition, you might need to review default information for the tank. You can select an option to access the Default Tank Information program.

The Temperature and TT fields are provided by default from the Default Tank Information table (F41508).

- Other Volume

-

Enter a number that represents any volumes that will affect the net volume calculation. The default value equals the pipeline volume plus the discharge volume. The pipeline and discharge volumes are from Additional Tank Information data. (Net volume = gross dip volume − water dip volume + other volumes.)

Pipeline plus discharge volume is added to the volume entered or retrieved from the strapping table.

If you enter a weight, the value is converted to a weight unit of measure using temperature and density information. It is then added to the quantity entered.

- Display Density

-

Enter the company's standard for density. You can also use this field for pack size and weight information.

- D T (density type)

-

Enter a code used to identify the type of density. Values are:

A: Absolute Density

G: API Specific Gravity

R: Relative Density

- Density Temp (density temperature)

-

Enter the temperature at which the density was measured. The system uses the density temperature type from Branch/Plant Constants - Page 3 Row exit.

- T U (thermometer used)

-

Specify the scale type of the thermometer being used to measure temperature. Values are:

F: Fahrenheit

C: Celsius

- Vapour Pressure

-

Enter the observed LPG vapour pressure. The system compares this value to the equilibrium vapour pressure to check for inert gases. The observed pressure of the LPG vapour is recorded as part of the tank dip, and it is used in the calculation of the liquid equivalent volume of the vapour.

- LPG Vap Temp (LPG vapour temperature)

-

Enter the standard vapour temperature at the item level. The observed temperature of the vapour in the LPG tank is recorded as part of the tank dip and is used to calculate the liquid equivalent volume of the vapour.

If you calculate LPG vapour, enter the standard LPG vapour. The observed vapour from the Dip Volume Calculator and Multimeter Reading is compared to this value.

- S T (slip tube)

-

Enter the slip tube type for a dip reading for an LPG Slip Tube type tank. This field denotes whether this is a long or short slip tube reading. Values are:

L: Long

S: Short. If you leave this field blank, the system uses S.

- Vapour Weight

-

Enter the weight of the vapour within a tank or containers.

8.5.4 Calculating Volume for a Simultaneous Movement

Access the Discharge Meter Readings form.

- Meter Number

-

Specify the meter.

- Opening Reading

-

Enter the beginning (opening) meter reading before the product flows through a pipeline. To calculate the ambient volume, an after (closing) meter reading is required.

- Closing Reading

-

Enter the closing reading of the meter at the date and time specified by the user.

This value indicates the quantity of product that has flowed through the meter when the closing readings are taken. To calculate the ambient volume, an after (closing) meter reading is required.

8.6 Calculating Volume from Weighbridge Information

This section provides an overview of volume calculation from weighbridge information and discusses how to calculate volume from weighbridge information.

8.6.1 Understanding Volume Calculation from Weighbridge Information

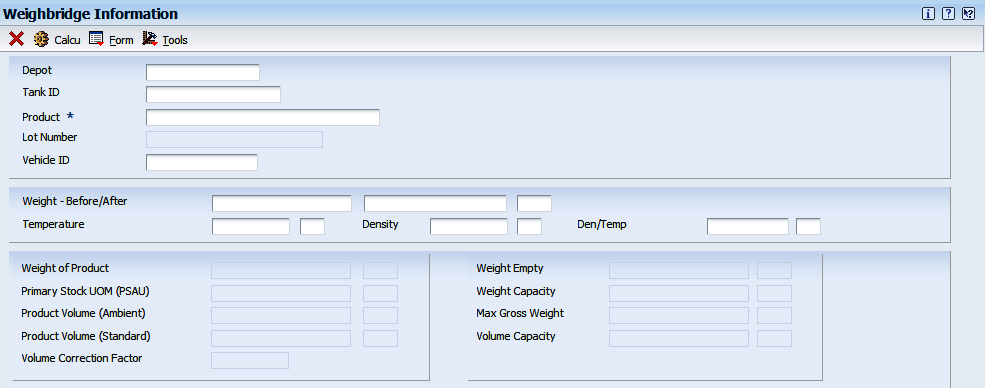

You use the Weighbridge Information program (F41511) to calculate volume for stock movements when you have weight readings from a weighbridge. This program calculates the weight or volume of the product by subtracting the weight of the vehicle. The program stores weighbridge calculations in the Bulk Product Transaction File table (F41511) when calculating volume is performed as part of a stock movement.

The system calculates:

-

Weight (by subtracting the weight before loading from the weight after loading).

-

Ambient volume.

-

Standard volume.

-

PSAU quantity (either weight or volume).

The Weighbridge Information program requires that:

-

The Before Loading weight cannot be below the empty weight of the vehicle.

-

The After Loading weight cannot exceed the weight capacity or maximum gross weight of the vehicle.

-

The volume the system calculates cannot exceed the volume capacity of the vehicle.

You can access the Weighbridge Information program directly from the Bulk Stock Management menu (G41501), by selecting Weighbridge from the row menu on any stock movement form on the Stock Movements menu (G415011). Alternatively, from the Purchase Order Receipts form, select Bulk, and then Weighbridge from the Row menu.

If you access Weighbridge Information directly from the Bulk Stock Management menu, the program serves as a calculation tool only. It does not store the values.

When you calculate volume from weighbridge information, the system provides temperature type values by default from the Default Tank Information table.

The system performs volume calculations and retrieves values for these fields:

-

Weight of Product

-

Primary Stock UOM (unit of measure) (PSAU)

-

Product Volume (Ambient)

-

Product Volume (Standard)

-

Volume Correction Factor

If you need to review information for the vehicle, you can select Weight Information from the Form menu to access the Vehicle Master program.

8.6.2 Forms Used to Calculate Volume from Weighbridge Information

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| General Stock Movements | W415101B | Stock Movements (G415011), Bulk Stock Adjustments, Consumed In Operations-Own Use, Tank to Tank Transfer, Repacking, Rebrand, Regrade, Decanting, Filling, or Simple Blending

Click Add on the Work With General Stock Transactions form. |

Enter general stock movement information. |

| Weighbridge Information | W415104A | On the General Stock Movements form, select Weighbridge from the Row menu. | Calculate volume from weighbridge information. |

8.6.3 Calculating Volume from Weighbridge Information

Access the Weighbridge Information form.

- Depot

-

Enter an alphanumeric code that identifies a separate entity within a business.

- Tank ID

-

Enter a code that identifies a tank.

- Product

-

Enter the item number that the system assigns to the item.

- Lot Number (Lot Number)

-

Enter a number that identifies a lot.

- Vehicle ID

-

Enter a unique number that identifies a vehicle.

This number serves as a primary identifier for a vehicle.