Understanding POU Supplier Systems

Understanding POU Supplier Systems

This chapter provides an overview of point-of-use (POU) supplier systems and discusses how to:

Define par location data for the POU supplier and the PeopleSoft system.

Manage item replenishment data in the POU supplier and the PeopleSoft system.

Restock a POU supplier.

Use POU supplier enterprise integration points (EIPs).

Understanding POU Supplier Systems

Understanding POU Supplier Systems

This section discusses:

General assumptions about POU supplier systems.

Definition of items and par locations.

Chunking Rules for streamlining POU supplier integration processes.

POU suppliers as par locations in PeopleSoft Inventory.

Returns to vendors (RTVs) for POU supplier items.

You can integrate PeopleSoft Inventory par location functionality with POU supplier systems. This integration consists of generic EIPs, using service operations in PeopleSoft Integration Broker to exchange applicable par location, item counts, and expected receipt information between the PeopleSoft system and the POU supplier.

This chapter describes the implementation of a full integration between POU medical supply dispensing cabinets and PeopleSoft. The use of POU supplier systems for issuing medical supplies is prevalent in today's typical hospital environment. POU supplier systems maintain available stores of medical supplies for the immediate and ad hoc needs of a hospital's surgical, nursing, and distribution staff during normal operations. A POU supplier system maintains on-hand quantities at all times and records patient usage as it occurs.

A POU supplier system can be a complete standalone system, but it is usually integrated with a hospital's materials management information system (MMIS), such as PeopleSoft Inventory and PeopleSoft Purchasing. Integrating a POU supplier system with an MMIS can help a healthcare organization achieve maximum benefit from its investments on both fronts.

In this integration scenario, the PeopleSoft system is responsible for:

Defining and maintaining the par location and item information.

Issuing stock from inventory to the par locations.

Performing the receipt of purchased goods.

Replenishing the materials to the par locations.

The POU supplier systems are responsible for:

Keeping track of the stock on hand in the POU locations.

Capturing the use of the medical supplies issued.

That use can in turn be charged directly to a specific patient's account. If the charges are made directly to patient accounts, the POU supplier system is also usually integrated with the hospital's patient accounting or clinical systems.

Assumptions About POU Supplier System Integration

Assumptions About POU Supplier System Integration

The POU supplier system integration works as designed only if you understand the following assumptions and your system complies with them:

Because patient usage is recorded in the POU supplier system and not in PeopleSoft Inventory, the material usage and reconciliation feature in PeopleSoft Inventory should not be used.

Any reconciliation procedures must be handled by the POU supplier system.

If you use POU supplier systems in some locations and PeopleSoft Inventory par locations in others, and if you plan to use the consumer usage feature, you need to set up two feeds to the admission, discharge, and transfers and patient billing systems: one from PeopleSoft and one from the POU supplier system.

If a POU supplier is reconfigured, for example, if bins are removed, added, or moved, the physical reconfiguration of the POU supplier needs to occur first, followed by the manual online maintenance of the par location in PeopleSoft Inventory.

The Par Location EIP transactions are then published to update the supplier accordingly.

All par locations, whether integrated with a POU supplier system or not, are replenished using the PeopleSoft Inventory Create Par Replenishment Requests process (INPGCDMD).

Definition of Items and Par Locations for

a POU Supplier Integration

Definition of Items and Par Locations for

a POU Supplier Integration

All item and par location data is set up and maintained in the PeopleSoft system. However, a successful integration with a POU supplier depends on understanding how the POU supplier system uses the fields that you define in the PeopleSoft system. Here are two important points to keep in mind:

The charge code and the usage tracking method (charge type) are required fields for every item in the par location for use with POU supplier systems.

Because the POU suppliers pass patient usage information directly to a patient billing system, these two pieces of information are vital. Both fields are part of the par location definition created in the Par Location Definition component, and they are included in the par location data that PeopleSoft Inventory sends to the POU supplier system.

The same item can exist in a par location in both the PeopleSoft system and POU supplier system.

The compartment in the PeopleSoft system and the bin in the POU supplier both identify the unique location of an item in the POU par location. The POU supplier's bin is a system-generated, assigned field and the PeopleSoft system's compartment field cannot be fed into it. The POU supplier system needs to process the PeopleSoft compartment information separately to avoid data update conflicts.

See Also

Chunking Rules for Streamlining POU Supplier

Integration Processes

Chunking Rules for Streamlining POU Supplier

Integration Processes

You can use the PeopleSoft chunking methodology to reduce the volume of data that are sent in the outbound publishing process. Chunking enables you to segment a transaction by business unit and location or par location and define which nodes receive the specific information. This functionality is especially helpful if not all of your subscribing nodes need to receive the data published by all departments. For example, you can set up processes so that business units and locations that exist as subscribers in third-party systems receive only the data that are specifically published for them according to the chunking rules and node maps that you implement.

See Also

Enterprise PeopleTools PeopleBook: Integration Broker

POU Suppliers as Par Locations in PeopleSoft

Inventory

POU Suppliers as Par Locations in PeopleSoft

Inventory

Rather than setting up POU suppliers as PeopleSoft Inventory business units, you can set up your system to track POU suppliers as par locations within PeopleSoft Inventory. In this case, par location replenishment transactions for affected items must be subject to the same replenishment rules in PeopleSoft Inventory or PeopleSoft Purchasing.

However, the PeopleSoft system is not responsible for consumer charges because POU supplier systems pass this information to the consumer accounting system. The direct purchase and direct inventory issue processes to the POU suppliers should remain as originally designed in the PeopleSoft system.

See Also

RTVs for POU Supplier Items

RTVs for POU Supplier Items

A PeopleSoft Purchasing RTV should be created if an incorrect item is delivered for replenishing a POU supplier. This kind of mistake is typically discovered at the main loading dock of the healthcare facility. However, if the item has already been received into PeopleSoft Purchasing, a transaction will have already been published to the POU supplier system. In this case, the POU supplier never receives the shipment and the system never fills the PO Receipt Notification transaction that is issued for the item.

See Also

https://support.oracle.com/CSP/ui/flash.html

Defining Par Location Data for the POU Supplier

and the PeopleSoft System

Defining Par Location Data for the POU Supplier

and the PeopleSoft System

This section discusses the procedures and application functions that are used to maintain par location data in PeopleSoft Inventory and the POU supplier system. Here are steps for defining and maintaining the par location data:

Decide on and document the specifications for the POU supplier configuration.

You build the POU supplier system based on the specifications (for example, compartment sizing, capacity, and so forth). Thoroughly document the system requirements.

Create par locations in the PeopleSoft system that correspond to the POU supplier.

Once you determine the configuration of the supplier and build the POU supplier system, create the corresponding par location in the PeopleSoft system by using the Par Location Definition component. You set up and maintain all item and par location data in the PeopleSoft system.

Run the Full Data Publish process to initially populate the POU supplier with item data.

Use the Full Data Publish process (available under the Manage Integration Rules menu) to publish a full-data replication of the par locations for the initial implementation by using the PAR_LOCATION_FULL_SYNC service operation (EIP). Run this process after the par locations are defined. This service operation is used to initially populate the POU supplier with par location item data.

Save changes to the Par Location Definition component to update the POU supplier.

All subsequent changes saved to the Par Location Definition component for existing par locations are sent to the POU supplier in partial-data replication (PAR_LOCATION_SYNC service operation) using the Par Location EIP. These partial-data replications are published when saving the Par Location Definition component to keep the POU supplier current with ongoing PeopleSoft Inventory par location definitions and item changes.

See Also

Understanding PeopleSoft Supply Chain Management Enterprise Integration Points

Managing Item Replenishment Data in the

POU Supplier and the PeopleSoft System

Managing Item Replenishment Data in the

POU Supplier and the PeopleSoft System

This section discusses the procedures and application functions used to manage item replenishment data in POU suppliers and PeopleSoft. Here is the process for managing item replenishment data:

The POU supplier system tracks on-hand quantity and material usage.

The POU supplier system maintains on-hand quantities for each of its par location items set up in the PeopleSoft Inventory Par Location Definition component, and it records consumer material usage throughout the day.

The POU supplier system publishes on-hand par location count data to PeopleSoft Inventory.

The POU supplier uses the Par Location Count EIP to publish on-hand par location count data to PeopleSoft Inventory. This publication occurs at user-requested intervals from the POU supplier to provide the PeopleSoft system with current on-hand quantities for each item in the POU par locations.

PeopleSoft Inventory subscribes to the on-hand par location count data from the POU supplier system.

PeopleSoft Inventory uses the Par Location Count EIP to subscribe to this data. Once the data is received, the PeopleSoft system updates the par location count tables and the par location count information is ready to be processed using the Create Par Replenishment Requests process (INPGCDMD).

Note. Any existing POU supplier-based replenishment processes are not used in this integration.

Run the Create Par Replenishment Requests process (INPGCDMD) in PeopleSoft Inventory.

The Create Par Replenishment Requests process takes each par location count and replenishes items that fall below the par level that you identify on the Par Location Definition - Line page. A purchase order, requisition, or material stock request is created in the PeopleSoft system to replenish the stock to par levels.

Deplete the material stock requests created to replenish a POU supplier.

For material stock requests that have issued stock from inventory to the par location and have been depleted, the Internal Location Expected Receipt EIP publishes data to the POU application using the IN_PUB_MSG Application Engine process.

Receive direct-purchase items with the Receiving component in PeopleSoft Purchasing.

Receiving material against a purchase order in the Receiving component in PeopleSoft Purchasing triggers the publication of a data transaction to the POU supplier using the Purchase Order Receipt Notification EIP. This transaction identifies all direct-purchase items and quantities that have been received and are delivered to specified locations. The Receipt Push process (RECVPUSH) loads the stage table (RECV_PUSH_NTFY). If a chunking rule for the service operation and publish rule exists on the publish rule definition table (EO_MSGPUBDEFN), then the system creates staging records for only those par location receipt transactions that have the par location defined on the par location chunking table (IN_BU_PAR_EOC). If the chunking rule does not exist, then staging records are created for all par location receipt transactions. Once the stage table is loaded, it calls the program that in turn publishes the receipt notification data.

See Also

Understanding PeopleSoft Supply Chain Management Enterprise Integration Points

https://support.oracle.com/CSP/ui/flash.html

Integrating With a Third-Party Surgical Resource Software Application

Restocking a POU Supplier

Restocking a POU Supplier

This section discusses the typical procedure used to physically restock POU supplier systems. Here are the steps:

Generate the appropriate reports for the material to be restocked at the POU supplier.

Typically, the technician assigned to restock the POU supplier is prompted through the POU supplier restock event by the light guides on the POU supplier unit. The lights are activated based on the information in the data sent using the Internal Location Expected Receipt EIP (outbound) or Purchase Order Receipt Notification EIP (outbound).

For item issues out of inventory, the Shipping Document Report page (INC6503) can be requested to accompany the delivery of the stock items to the POU par location. For purchased items, the Receiver Delivery report (POY5030) can be generated to accompany the stockless and non-stock items to the POU par location.

The restock technician can then use these reports along with the light guides on the POU to ensure that the par locations are updated with the correct quantities.

Compare expected receipts with actual receipts, and record discrepancies.

When restocking a light-guided POU supplier, the technician follows the lights on the POU supplier and, for each item, verifies that the quantity displayed, or the expected receipt quantity, is the same as the actual quantity received. If the quantity received is different from the expected quantity, the technician records the variation on the report.

Manually restock the POU bin or compartment with the received stock.

The technician refills the bins or compartments in the POU supplier with the received stock.

Complete the restocking event in the POU supplier system.

The final step of the restocking event takes place in the third-party POU supplier system. Typically, the technician updates the POU supplier system with the actual quantities that are used to restock the POU supplier bins or compartments.

Using POU Supplier EIPs

Using POU Supplier EIPsFour EIPs (service operations in PeopleSoft Integration Broker) are used to exchange data between the PeopleSoft Inventory and the POU supplier systems. They are:

Purchase Order Receipt Notification EIP (outbound).

Following the Data Flow Between the PeopleSoft

System and the POU Supplier System

Following the Data Flow Between the PeopleSoft

System and the POU Supplier System

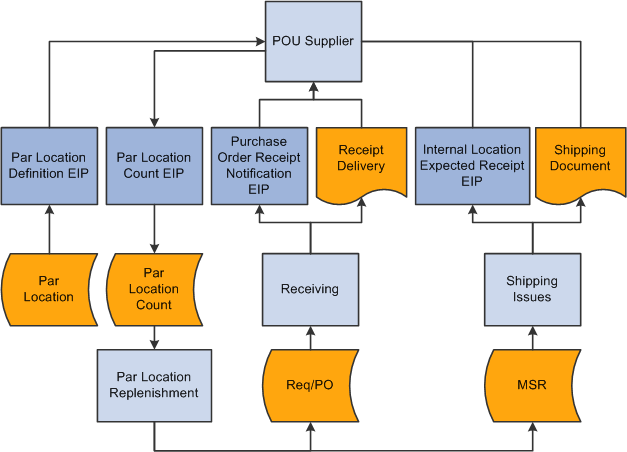

The following diagram illustrates the data flow between a POU supplier and PeopleSoft, including integration for par location counts, receipts, and internal location expected receipts:

POU supplier integration with a PeopleSoft system

See Also

Defining Par Location Data for the POU Supplier and the PeopleSoft System

Understanding PeopleSoft Supply Chain Management Enterprise Integration Points

https://support.oracle.com/CSP/ui/flash.html

Managing Subscription Errors for POU EIPs

Managing Subscription Errors for POU EIPs

Error management is integral to the effectiveness of inbound EIPs in the PeopleSoft system. In the process of uploading data transactions, the PeopleSoft subscription process detects any data errors and stores them in queues or staging tables for manual correction in the PeopleSoft system before updating any core PeopleSoft application tables.

Each of the inbound EIPs facilitating the subscription of transactions from third-party applications has its own transaction code that must be entered on an assigned data management page to access the EIP's specific error-correction page.

The Par Location Count EIP, which is used in both surgical resource system and POU supplier system integrations, uses the transaction codePar Loc, which is entered on the Transaction Maintenance page. You use the Transaction Maintenance page to access error-correction pages for transactional data.

See Also

Understanding PeopleSoft Supply Chain Management Enterprise Integration Points