Understanding the PeopleSoft Purchasing

Default Hierarchy

Understanding the PeopleSoft Purchasing

Default Hierarchy

This chapter provides overviews of:

PeopleSoft Purchasing default hierarchy.

Unit of measure (UOM) conversion hierarchy.

Matching default hierarchy.

Vendor location hierarchy and multicurrency pricing.

Multicurrency conversions.

Value-added tax (VAT) drivers, VAT driver keys, and the defaulting hierarchy for VAT defaults.

Understanding the PeopleSoft Purchasing

Default Hierarchy

Understanding the PeopleSoft Purchasing

Default Hierarchy

For each business unit that you define in PeopleSoft Purchasing, you establish default information used in all transaction processing. Depending on the fields that you define, you can specify default information at each applicable level in the hierarchy or have default fields obtain their values from default values designated at less-specific levels in the hierarchy.

PeopleSoft Purchasing provides default capability for those values that are relatively static in nature (values that remain the same in everyday operations and would become repetitive to enter for every transaction). For example, if you set up the ChartField defaults with the most appropriate values for the items, categories, and requesters, theoretically, you have little need to navigate to the requisition's distribution level to enter any values. The ChartField values at that level are set by default.

PeopleSoft defaults operate in two parallel areas: transactions and items.

Transaction defaults begin at the more-specific buyer level in the hierarchy and end with the most-general user level.

Item defaults begin at the most-specific ship to level and end at the most-general item category level.

Purchasing Transaction Default Hierarchy

Purchasing Transaction Default Hierarchy

This list illustrates an overview of the PeopleSoft Purchasing transaction default hierarchy, where each level represents a factor in the procurement process that can provide a transaction default value:

Level One: Buyer.

Level Two: Requester.

Level Three: Vendor.

Level Four: Purchase Order Origin.

Level Five: Business Unit.

Level Six: User.

The first level, represents the buyer level, one of the most specific default levels. Level six, the last level, represents the user level, which is one of the least-specific default levels. When determining which value to use on a purchase order, the system references the highest default level for a value. If it cannot find one there, it moves down level by level, searching for a defined value.

This table details the levels in the transaction default hierarchy from which the selected transaction values can appear by default. The possible default hierarchy levels listed for each transaction field value begin with the more-specific default and end with the less-specific default.

For example, when determining the accounting template to use for a purchase order, the system first determines whether a vendor has defined an accounting template. If so, the system uses the vendor's accounting template. If a template is not defined at the vendor level, the system uses the accounting template defined at the business unit level.

|

Transaction Field Value |

Default Hierarchy |

|

Accounting Template |

Vendor, Business Unit |

|

AM Capitalize Flag |

Business Unit |

|

AM Unit |

Business Unit |

|

AP Accrue Flag |

Business Unit |

|

AP Unit |

Business Unit |

|

ASN Flag |

Vendor |

|

Billing Location |

Business Unit |

|

BU Comments (business unit comments) |

Business Unit |

|

Business Unit |

User |

|

Buyer |

Vendor, User |

|

Catalog ID |

Requester |

|

Contract Authority |

User |

|

Contract Dispatch Method |

Vendor, Business Unit |

|

Contract Status |

User |

|

Country |

Vendor, User |

|

Currency |

Requester |

|

Currency Code/Rate Type |

Vendor, Business Unit |

|

Days + / - Today |

User |

|

Department |

Buyer, Requester, Purchase Order Origin, User |

|

Fax |

Requester |

|

Freight Terms |

Vendor, Business Unit |

|

GL Unit (general ledger unit) |

Business Unit |

|

Location Code |

Buyer, Requester, Business Unit, User |

|

Match Option/Match Type |

Vendor, Business Unit |

|

Order Location |

Vendor |

|

Origin |

Buyer, Requester, Business Unit, User |

|

Override Vendor |

Buyer |

|

Payment Terms |

Vendor, Business Unit |

|

Payment Terms Basis Date |

Vendor |

|

Phone |

Buyer, Requester |

|

PO Authority |

User |

|

PO Dispatch |

Vendor, Business Unit |

|

PO Status |

Buyer, User |

|

Pricing Location |

Vendor |

|

Receiving Authority |

User |

|

Receiving BU |

User |

|

Replenishment Dispatch Method |

Vendor |

|

Report Template |

Business Unit |

|

Requester Name |

User |

|

Requisition Authority |

Requester, User |

|

Requisition Status |

Requester, User |

|

Returning Location |

Vendor |

|

RFQ Authority (request for quotation authority) |

User |

|

RFQ Dispatch Method |

Vendor, Business Unit |

|

RFQ Status |

User |

|

RTV Debit Memo (return-to-vendor debit memo) |

Vendor |

|

RTV Dispatch Method |

Vendor, Business Unit |

|

RTV Fees |

Vendor |

|

RTV Notification Method |

Vendor |

|

RTV Replace Invoice |

Vendor |

|

Sales Tax Tolerance |

Vendor |

|

Sales/Use Tax Information |

Vendor |

|

SetID |

User |

|

Ship To |

Buyer, Requester, User |

|

Ship Via |

Vendor, Business Unit |

|

Sourcing % Unit Price Tolerance (sourcing percentage unit price tolerance) |

Business Unit |

|

Tax Exempt Flag/Tax Exempt ID |

Business Unit |

|

Use VAT Suspension (use value-added tax suspension) |

Business Unit |

|

VAT Calculation Type |

Business Unit |

|

VAT Declaration Point |

Business Unit |

|

VAT Home |

Business Unit |

|

VAT Options |

Vendor, Business Unit |

|

VAT Registration ID |

Business Unit |

|

VAT Rounding Rule |

Business Unit |

|

VAT Tolerance Check Indicator |

Business Unit |

|

VAT Transaction Code |

Business Unit |

|

Vendor Authority |

User |

Requisition Default Hierarchy

Requisition Default Hierarchy

PeopleSoft Purchasing enables you to create requisitions using requisition loader batch processing or the requisition online entry pages.

The Purchasing Requisition Loader Application Engine process (PO_REQLOAD) derives its most specific default values from the data sources of this batch process. At a less specific level, you can use the Requisition Loader Defaults page to set the default values for the Purchasing Requisition Loader process. These default values populate empty requisition ChartFields when you run the process. Use the Requisition Loader Defaults - Overrides and Options page to set override options for the Purchasing Requisition Loader process. These values replace source requisition ChartField values when you run the process.

After you create requisitions from the online entry pages, use the Maintain Requisitions - Requisition Defaults page to set defaults for requisitions at the individual transaction level. This page gives you the option to do the following for all future requisition lines:

Specify default values.

The application references the default values specified in the existing hierarchy to populate fields on future lines. If no values are found, it uses the values defined on this page as defaults.

Specify overriding values.

The application references the values that you defined on this page to populate fields on the requisition for future lines.

If you have pre-existing defaults on the Requisitions - Header or Line Defaults pages and you change any of these values, PeopleSoft Purchasing enables you to retrofit these changes to existing requisition lines and distributions.

See Also

Applying Changes to Default Values in Requisition Header, Line, Schedule, and Distribution Fields

Entering Requisition Header Defaults

Understanding the Purchasing Requisition Loader Application Engine Process (PO_REQLOAD)

Using Requisition Loader Defaults and Overrides

Purchase Order Default Hierarchy

Purchase Order Default Hierarchy

PeopleSoft Purchasing enables you to create purchase orders using purchase order staging batch processing or the purchase order online entry pages.

The PO Stage Load Application Engine process (PO_POSTAGE) derives its more specific default values from the data sources of this batch process. At a less-specific level, you can use the PO Loader Defaults page to set the default values for the PO Stage Load process. These default values populate empty purchase order ChartFields when you run the process. You can also use the PO Loader Defaults - Overrides and Options page to set override options for the Create Purchase Orders Application Engine process (PO_POCREATE). These values replace existing purchase order ChartField values when you run the process.

Once you create purchase orders from either online or batch processes, use the Purchase Order Defaults page to set defaults for purchase orders at the individual transaction level. The page gives you the option to do the following for all future purchase order lines:

Specify default values.

The application references default values specified in the existing hierarchy to populate fields on future lines. If no values are found, it uses the values defined on this page as defaults.

Specify overriding values.

The application references the values that you defined on this page to populate fields on the purchase order for future lines.

If you have pre-existing defaults on the PO Header Defaults pages and you change any of these values, PeopleSoft Purchasing enables you to retrofit these changes to existing purchase order lines and distributions.

See Also

Applying Default Field Value Changes to Existing Lines, Schedules, and Distributions

Entering Purchase Order Defaults

Loading Staged Purchase Order Requests from PeopleSoft Supply Planning and Manufacturing

Using Purchase Order Loader Defaults and Overrides

Purchasing Item Default Hierarchy

Purchasing Item Default Hierarchy

This list illustrates an overview of the PeopleSoft Purchasing item default hierarchy, where each level represents a factor in the procurement process that can provide an item default value:

Level One: Ship To Location

Level Two: Regions

Level Three: Kit Item

Level Four: Item/Vendor Attributes

Level Five: Item BU Attributes

Level Six: Item Purchasing Attributes

Level Seven: Item

Level Eight: Item Category BU Attributes

Level Nine: Item Category

The first level is the ship to location level, which is one of the most-specific default levels. Level nine, the last level, represents the item category level. Level nine is one of the least-specific default levels. When determining which value to use for an item, the system first references the highest default level for a value. If it cannot find one there, it moves down the relevant levels, searching for a defined value to use.

This table details the levels in the item default hierarchy from which the selected transaction values can appear by default. The possible default hierarchy levels listed for each item-related field value begin with the more-specific default and end with the most-general level default.

For example, when determining the asset profile ID for an item, the system first references the item purchasing attributes to determine whether an ID is defined. If so, the system uses that asset profile ID. If an ID is not defined, the system uses the asset profile ID defined at item category level.

Text in boldface indicates a grouping of default fields, rather than just a single field, for example, matching controls and sourcing controls.

|

Transaction Field Value |

Default Hierarchy |

|

Asset Profile ID |

Item Purchasing Attributes, Item Category |

|

Buyer |

Item BU Attributes, Item Purchasing Attributes, Item Category-BU Attributes, Item Category |

|

Currency Code |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Origin Country |

Item/Vendor Attributes |

|

Description |

Item Purchasing Attributes, Item |

|

Delivery Instructions |

Ship To Location |

|

Distribution Network |

Ship To Location |

|

Inventory BU |

Ship To Location |

|

Item/Item Category |

Ship To Location |

|

Item Specifications |

Item Purchasing Attributes |

|

Lead Time Days |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Long Description |

Item Purchasing Attributes, Item |

|

Lot Item |

Item |

|

Manufacturer ID |

Item/Vendor Attributes, Item |

|

Manufacturer Item ID |

Item/Vendor Attributes, Item |

|

Matching Controls: Unit Price Tolerance Over, Unit Price Tolerance Under, % Unit Price Tolerance Over, % Unit Price Tolerance Under, Ext. Price Tolerance Over, Ext. Price Tolerance Under, % Ext. Price Tolerance Over, % Ext. Price Tolerance Under |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Miscellaneous Controls and Options |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Accept Any Ship To |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes |

|

Accept Any UOM |

Item/Vendor Attributes |

|

Accept Any Vendor |

Item BU Attributes, Item Purchasing Attributes |

|

Auto Select |

Item BU Attributes, Item Purchasing Attributes |

|

Close PO Under Percent Tolerance |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Contract Required |

Item BU Attributes, Item Purchasing Attributes |

|

RFQ Required |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes |

|

Stockless Item |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes |

|

Taxable |

Ship To Location, Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes |

|

Tax Exempt Information |

Ship To Location |

|

Ultimate Use Code |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Order Location |

Ship To Location, Region |

|

Packing Weight |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes |

|

Packing Weight UOM |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes |

|

Packing Volume |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes |

|

Packing Volume UOM |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes |

|

Price (vendor) |

Item/Vendor Attributes |

|

Price (standard) |

Item BU Attributes, Item Purchasing Attributes |

|

Price Can Be Changed On Order |

Item/Vendor Attributes |

|

Receiving BU |

Ship To Location |

|

Receiving Controls |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Early Ship Reject Days |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Inspection ID |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Inspection Required |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Inspect Sample % |

Item BU Attributes, Item Purchasing Attributes |

|

Inspection UOM |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Partial Quantity |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Quantity Received Tolerance % |

Item/Vendor Attributes, Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Receiving Required Flag |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Reject Quantity Over Tolerance |

Item BU Attributes, Item Purchasing Attributes, Item Category |

|

Region of Origin |

Item/Vendor Attributes |

|

Sales/Use Tax Information |

Ship To Location |

|

Serial Item |

Item |

|

Ship Via |

Item BU Attributes, Item Purchasing Attributes, Item |

|

Standard or Vendor UOM |

Item/Vendor Attributes |

|

Standard UOM |

Item |

|

Rounding Tolerance |

Item/Vendor Attributes |

|

RTV Information: RTV Miscellaneous Charge, RTV Action, RTV Percent, RTV Reason |

Item/Vendor Attributes |

|

Sourcing Controls |

Item Purchasing Attributes, Item Category |

|

Use Category Sourcing Controls |

Item Purchasing Attributes |

|

Vendor Sourcing Priorities |

Item Category |

|

Sourcing Method |

Item Purchasing Attributes, Item Category |

|

Accumulate Level |

Item Category |

|

Lead Time Factor % |

Item Purchasing Attributes, Item Category |

|

Price Factor % |

Item Purchasing Attributes, Item Category |

|

Ship To Priority Factor % |

Item Purchasing Attributes, Item Category |

|

Vendor Priority Factor % |

Item Purchasing Attributes, Item Category |

|

Cumulative Sourcing: Year to Start, Month to Start, Number of Months, Start Date, End Date |

Item Category |

|

Vendor Sourcing Priorities |

Item Category |

|

Priority |

Ship to Location, Region, Item/Vendor Attributes, Item Category |

|

Vendor ID |

Ship to Location, Region, Item/Vendor Attributes, Item Category |

|

Allocation Percentage |

Item/Vendor Attributes, Item Category |

|

Use Item Standard Lead Time |

Item/Vendor Attributes |

|

Use Standard Item Tolerance |

Item/Vendor Attributes |

|

Vendor History: Number of Months, Month to Start |

Item Category |

Purchasing ChartField Default Hierarchy

Purchasing ChartField Default Hierarchy

This list illustrates an overview of the PeopleSoft Purchasing ChartField default hierarchy, where each level represents a factor that can provide a ChartField default value.

Level One: Purchasing Kit Items.

Level Two: Item BU Attributes.

Level Three: Item Purchasing Attributes.

Level Four: Item Category.

Level Five: Requester.

The first level represents the purchasing kit item setup, one of the most-specific default levels. Level five represents the requester level, one of the least-specific default levels. When determining which ChartField value to use, the system first references the highest default level for a value. If it cannot find one there, it moves down the relevant levels, searching for a defined value.

Understanding the UOM Conversion Hierarchy

Understanding the UOM Conversion Hierarchy

All of the PeopleSoft applications use UOMs to quantify resources. In PeopleSoft Purchasing, the various UOMs that are available for the transactions enable you to quantify and track the items that you have purchased.

You must first define the UOM codes to be used in the system on the Units of Measure page. Use this page to define standard conversion rates between any combination of UOMs necessary. These codes are stored in the Units table.

These are the UOMs commonly used by PeopleSoft Purchasing transactions:

General UOM

The general UOM and its conversion rates are defined on the Units of Measure page. This information is stored in the Units table.

Inventory item UOM

The inventory item UOM is the UOM defined for the item on the Item Definition - Units of Measure page. The inventory item UOM rate of conversion to the item standard UOM is also defined on the Item Definition - Units of Measure page. The inventory item UOM information represents the UOM in which the item is tracked in the business process. This information is stored in the Inventory Item table.

Define an item standard UOM when you first enter an item definition into the system on the Item Definition - General: Common page. After transactions against the item are created, the standard UOM cannot be changed.

The item standard UOM serves as the smallest common denominator for UOM conversion, and should be selected accordingly. The standard UOM should be the smallest unit in which the item is transacted and should be selected, so that any conversions performed for the item are converted from the standard UOM.

For example, do not assign a standard UOM of CASE to an item that you regularly order in the smaller UOM of BOX or EACH.

Item vendor UOM

The item-vendor UOM is defined for an item-vendor combination on the Vendor's UOM & Pricing Info page. The item-vendor UOM rate of conversion to the item standard UOM is also defined on this page. The item-vendor UOM information represents the UOM in which the item is purchased from a specific vendor. This information is stored in the Item Vendor table.

See Also

Defining Purchasing Item Vendor UOM and Pricing Information

Associating an Item with a UOM

UOM Defaulting

UOM Defaulting

The PeopleSoft Purchasing UOM default hierarchy is based in part on the type of transaction that you create (RFQ, requisition, purchase order, contract, or procurement card). If a vendor is involved in the transaction, the setting of the Accept Any UOM check box for the vendor on the Purchasing Attributes - Item Vendor page is also a factor in the UOM default hierarchy.

This diagram illustrates the UOM default hierarchy:

UOM default hierarchy

When you enter a requisition with a specified item ID, the system searches for a preferred vendor for the item. If a preferred vendor exists, the preferred vendor default UOM appears on the requisition.

If the item ID that you add to a requisition has no vendor ID, the UOM appears by default in the item standard UOM defined for the item.

If you are creating an ad hoc, RFQ, or procurement card transaction, the system creates the transaction with the general UOM that you specify on the transaction.

See Also

Defining Attributes and Priorities for Purchasing Item Vendor Relationships

UOM Conversion Rate Defaults

UOM Conversion Rate Defaults

When you convert one transaction type to another, the UOM on the originating transaction may need to be converted to the UOM that is required for the new transaction. This kind of UOM conversion may be performed when you source a requisition to a purchase order, or award an RFQ and create a purchase order for it.

For example, suppose that you have a requisition with no vendor for a quantity of 10 boxes of an item in the inventory item UOM. When you source the requisition to a purchase order, and the vendor assigned to the purchase order does not accept any UOM, the item vendor UOM overrides the inventory item UOM. If the vendor has a preferred UOM of cases, the requisition quantity of 10 boxes in the inventory item UOM must be converted to the item vendor UOM of cases.

To accomplish this, the system uses the UOM conversion rate between boxes and the standard UOM defined on the Inventory Item table. It then accesses the UOM conversion rate between cases and the standard UOM defined on the Item Vendor table. If none exists, the system uses the conversion rate defined on the Inventory Item table. The system then reconciles the quantities in the standard UOM to derive the quantity to be ordered in the preferred item vendor UOM of cases.

If the chosen vendor accepts any UOM, you can create the purchase order from the requisition with the inventory item UOM, and no conversion is necessary.

When you source an ad hoc item transaction to a purchase order, the general UOM on the originating transaction is carried to the purchase order and no conversion is performed. This diagram illustrates the process:

UOM conversion default hierarchy

Understanding the Matching Default Hierarchy

Understanding the Matching Default Hierarchy

This section outlines the way in which matching and Evaluated Receipt Settlement (ERS) statuses appear by default onto vouchers, purchase orders, and receipts. Status flags determine the application of match rules to a purchase order, receipt, or voucher rather than the type of match control ID. The status flag settings are derived from the vendor location options and options at the PeopleSoft Payables business unit level or PeopleSoft Purchasing business unit level. ERS processing is further controlled by options at the PeopleSoft General Ledger business unit level (procurement accounting controls). Matching includes receipt-only matching (voucher to non-purchase order receipts).

This table illustrates the matching default hierarchy used in PeopleSoft Purchasing:

Matching default hierarchy table

Purchase Order Key

|

MATCH_STATUS_PO |

T (to match) N (not required) |

Receipt Key

|

MATCH_STATUS_RECV |

T (to match) N (not required) |

|

ERS_INV_DT_OPT |

F (freight terms) R (receipt date) N (none) |

Voucher Key

|

MATCH_STATUS_VCHR |

T (to be matched) N (not applicable) |

|

MATCH_ACTION |

Y (yes) N (no) E (evaluated receipt settlement) |

See Also

Understanding the Vendor Location Hierarchy

and Multicurrency Pricing

Understanding the Vendor Location Hierarchy

and Multicurrency Pricing

PeopleSoft Purchasing uses the vendor location hierarchies to determine vendors and various vendor locations for online requisitions. These hierarchies are also used by the PO Calculations Application Engine process (PO_POCALC) to determine the vendor necessary to create a purchase order and determines how pricing is ultimately derived based on this hierarchy.

This section also discusses how involvement of multicurrencies affects which pricing locations the system obtains. Depending on the setting of the multicurrency flags and which currencies have been set up for the purchasing business unit, requester, vendor location, and pricing locations, PeopleSoft Purchasing performs multicurrency conversions when required.

Here is the setup hierarchy for vendor location and pricing:

|

Level 1 |

When defined, the system uses Item Ship To Vendor Locations to determine the priority vendor and the vendor location specified for the item and ship to location. Based on the vendor and vendor location, the pricing location is derived from the Maintain Vendor setup. If not defined, it uses level 2 defaulting. |

|

Level 2 |

When defined, the system uses the Item Region Vendor Locations to determine the priority vendor and the vendor order location specified for the item and region. Based on the vendor and vendor location selected for the region, pricing location is derived based on the vendor and vendor location selected for the region by accessing the location details from the Maintain Vendor setup. If not defined, it uses level 3 defaulting. |

|

Level 3 |

The system selects the vendor based on the Item Vendor setup. When defined, the system uses the Ship To Vendor Location to get the vendor order locations to derive the pricing location from the Maintain Vendor setup. Ordering locations can be different from the default locations. If not defined, it uses level 4 defaulting. |

|

Level 4 |

The system selects the vendor based on the Item Vendor setup. When defined, the system uses the Region Vendor Location to get the vendor order locations to derive the pricing location from the Maintain Vendor setup. Ordering locations can be different from the default locations. If not defined, it uses level 5 defaulting. |

|

Level 5 |

When defined, the system uses the vendor priorities established in the Item Vendor setup to derive the pricing location from the Maintain Vendor setup. If the Item Vendor setup is the only one defined, the pricing location is always derived from the vendor default location. If not defined, there is no control hierarchy defined. |

You can define various locations for a vendor on the Vendor Information - Location page accessed from the Maintain Vendors menu. Each location that you define points to an ordering location and a pricing location.

The Item Ship To Vendor Location that you define on the Item Ship To Locations page is a setup based on the combination of the item and ship to location. This setup prioritizes the vendors from which the item can be purchased for a ship to location and determines the specific vendor location from which to get a pricing location.

The Item Region Vendor Location that you define on the Item Region Locations page is a setup based on the combination of the item and region. This setup prioritizes the vendors from which the item can be purchased for a region and determines the specific vendor location from which to get a pricing location. The region is derived from the shipto location on the requisition or staged purchase order's schedule.

The Ship To Vendor Location that you defined on the Ship To Locations page defines all of the vendors that can ship an order to a particular ship to location and is not item-specific. Each vendor and the appropriate vendor order location appears. When determining the vendor ordering location, the system first references the Item Vendor for the priority 1 vendor and then references the Ship To Location page to determine the order location.

The Region Vendor Location that you defined on the Region Locations page defines all of the vendors that can ship an order to a particular region and is not item-specific. Each vendor and the appropriate vendor order location appears. When determining the vendor ordering location, the system first references the Item Vendor for the priority 1 vendor and then references the Region Location page to determine the order location.

The Item Vendor setup dictates only vendor priorities, and establishes vendor UOM pricing for their pricing locations. This setup does not dictate vendor order locations for the item. Vendor ordering locations default from one of the hierarchies discussed previously or, if no higher level defaults are found, from the default location defined on the Maintain Vendor - Location page. The item vendor relationship that you defined on the Purchasing Attributes - Item Vendor page defines the pricing location for the vendor's default location.

Regardless of the setup that you implement, the pricing location the system uses is ultimately derived from the vendor ordering location. In addition, you can override anything that appears by default on the requisition. To ensure the override is carried to the purchase order, make sure that the Override Suggested Vendor check box is clear on the Maintain Requisition - Requisition page and the Let POCalc Override Vendor check box is clear on the Selected Item Details page accessed from the Sourcing Workbench.

By selecting this check box on the requisition, you enable the purchase order to be created using the same hierarchy and ignore all of the overriding information that the user enters on the requisition. Once the purchase order is created, the buyer can still override this information prior to dispatching.

For example, suppose that the user changes the vendor or vendor location that appear by default on the requisition, and the override suggested vendor check boxes are selected, the purchase order is created following the hierarchy. This overrides the user suggested vendor or vendor location on the requisition.

The purpose of defining the areas described here is to enable more control and automation in the system, thereby reducing the level of repetitive effort by the user. If you want a more automated system, a greater effort is required for the initial setup. This setup is a one-time effort that can increase the utilization of time-saving batch processing capabilities by the system. These setups require occasional updating as vendor changes occur.

Note. These setup scenarios are based on normal day-to-day practices. Exceptions are handled through manual intervention at the requisition, sourcing, or the purchase order level.

See Also

Defining Priority Vendors by Item Ship To Location

Defining Attributes and Priorities for Purchasing Item Vendor Relationships

Specifying High-Level Procurement Processing Options

High-Level Controls Implementation: Item

Ship To Vendor Location and Item Region Vendor Location Overview

High-Level Controls Implementation: Item

Ship To Vendor Location and Item Region Vendor Location OverviewEstablishing Item Vendor relationships associated with a ship to location or region provides the highest degree of control. These relationships are specific to the item and the ship to location or region, and enable definition of the vendor priority and vendor order location at a more granular level.

The ship to location is the most specific designation, which overrides both the Item Region Vendor Location and the Item Vendor priorities and location. Grouping ship to locations into regions provides the ability to override the Item Vendor prioritization and default vendor order location at the intermediate Item Region Vendor Location level. Both of these options, add flexibility to the default vendor selection hierarchy.

Item Ship To Vendor Location Setup

Item Ship To Vendor Location SetupDefining item ship to vendor locations provides the highest degree of control. This location-pricing relationship is specific to the item and ship to location. You can specify a multitude of ship to locations for one item and define different vendor priorities for the same item based on ship to locations. Indeed, this can require a large effort depending on the quantity of items and ship to locations that you have. However, time spent on this one-time setup saves time and repetitive effort in the future.

When you create the online requisition or when you source an existing requisition, the system references the item and ship to location of the requisition and accesses the item ship to location to get the priority 1 vendor and its vendor location. The system derives the pricing location that you defined for the vendor location. It then looks to the item-vendor relationship to access the pricing for the derived pricing location.

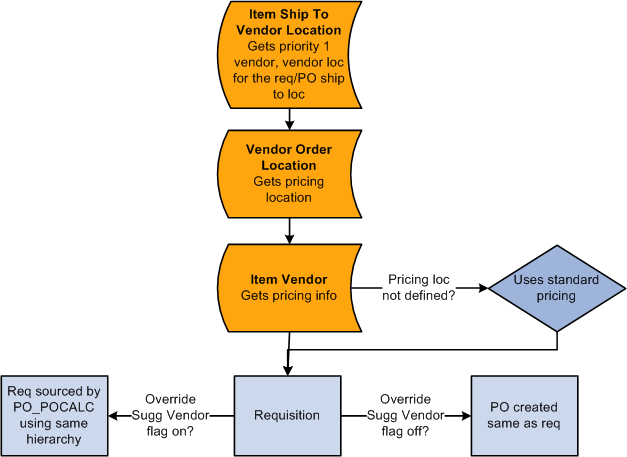

This diagram illustrates this default hierarchy:

Default Hierarchy using the Item Ship To Vendor Location setup

Item Region Vendor Location Setup

Item Region Vendor Location SetupA Ship to location can be associated to a region, allowing for management of similar ship to locations at the region level. Item region vendor locations provide a location-pricing relationship that is specific to the item and region. You can associate many regions to an item and define different vendor priorities for the same item based on region. This level of flexibility in vendor prioritization ensures the right suppliers are assigned to the purchase orders, without driving all of the maintenance down to the item ship to location.

When you create the online requisition or when you source an existing requisition, the system references the ship to location to determine the appropriate region. If the ship to location is assigned to a region and a lower level override for the Item Ship To Location does not exist, the system will accesses the item region vendor location to get the priority 1 vendor and its vendor location. The system derives the pricing location that you defined for the vendor location. It then looks to the item-vendor relationship to access the pricing for the derived pricing location.

Mid-Level Control Implementation: Ship To

Vendor Location and Region Vendor Location Vendor Order Location Overview

Mid-Level Control Implementation: Ship To

Vendor Location and Region Vendor Location Vendor Order Location OverviewEstablishing a vendor order location relationship with a ship to location or region provides an intermediate level of control (less control) in the vendor hierarchy. These relationships associate either a ship to location or a region to a vendor order location to override the Vendor's default order location.

With these additional levels of the hierarchy, the priority vendor is determined from the Item Vendor definition. Once the vendor ID is identified, the determination of the vendor order location begins with the ship to vendor location, then looks to the region vendor location and finally the vendor default location, as defined on the Maintain Vendors component.

Ship To Vendor Location Vendor Order Location

Setup

Ship To Vendor Location Vendor Order Location

SetupThe next level of control is provided by defining the vendor order location for each ship to location. The ship to location is based on the requester and buyer setups that include ship to location defaults for the requisition and purchase order.

One vendor ordering location for each vendor is defined for each ship to location. You can have more than one vendor for each ship to location but only one order location per vendor. This default system is not item-specific, but rather ship to location specific. This setup can require a large effort depending on the quantity of vendors and ship to locations that you have.

As you create an online requisition or when you source an existing requisition, the system references the item-vendor relationship to get the priority 1 vendor. The system then accesses the ship to location to determine the order location for the priority 1 vendor and uses the order location to derive the pricing location. The system then retrieves the pricing for the derived pricing location from the Item Vendor setup.

This diagram illustrates the default hierarchy for defining the ship to vendor order location for each ship to location:

Default Hierarchy using the ship to vendor location vendor order location setup

Region Vendor Location Vendor Order Location

Setup

Region Vendor Location Vendor Order Location

SetupUsing the procurement region enables you to group ship to locations for additional defaulting purposes. By defining the vendor order location for each region, you can override the default vendor order location for additional control, without maintaining these overrides for every ship to location in the buying organization.

One vendor ordering location for each vendor can be defined for each region. You can have more than one vendor for each region but only one order location per vendor. This default system is not item-specific, but rather region specific.

As you create an online requisition or when you source an existing requisition, the system references the item-vendor relationship to get the priority 1 vendor. Once the system determines the ship to location's region, it accesses the region vendor location definition to determine the order location for the priority 1 vendor and uses the order location to derive the pricing location. The system then retrieves the pricing for the derived pricing location from the Item Vendor setup.

Low-Level Control Implementation: Defining

Item-Vendor Relationships Overview

Low-Level Control Implementation: Defining

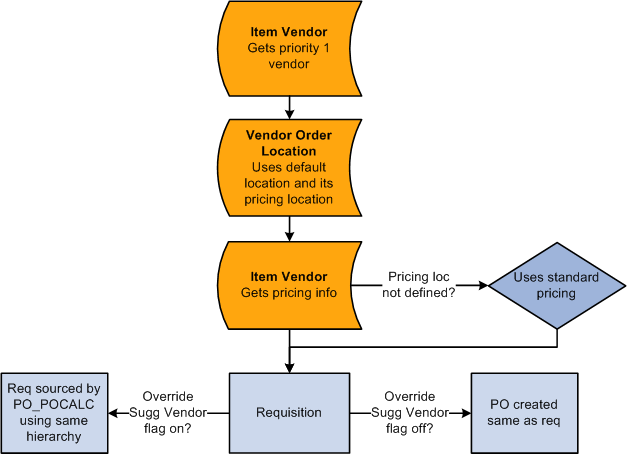

Item-Vendor Relationships OverviewThe least amount of control and setup effort occurs in the item-vendor setup scenario. In this case, you only define vendor priorities and vendor UOM pricing for the pricing locations of each established vendor. If neither item ship to location nor ship to location is defined, the system uses the priority 1 vendor default location to derive its pricing location. Any other vendor locations and pricing locations, if defined, are not considered. It then goes back to the item-vendor relationship to reference the pricing for the derived pricing location. This hierarchy applies to purchase orders created online.

This diagram illustrates the default hierarchy for defining item-vendor relationships:

Default hierarchy using the item-vendor setup

Zero-Level Control Implementation Overview

Zero-Level Control Implementation OverviewA zero-level of control results from not defining any of these setups, including no item-vendor relationships. In this scenario, no vendor automatically appears on the requisition, so the standard price is used. You can enter a suggested vendor, but the standard price remains. During the requisition selection process, you can select a vendor if the field is blank or change the vendor that the requester suggested. Because none of the setups were defined, the purchase order is built with the same pricing as the requisition or any buyer pricing updates are performed through requisition selection. Failure to establish item-vendor relationships prevents the creation of contracts. In the same scenario, purchase orders created online use the standard price as well.

Understanding Multicurrency Conversions

Understanding Multicurrency Conversions

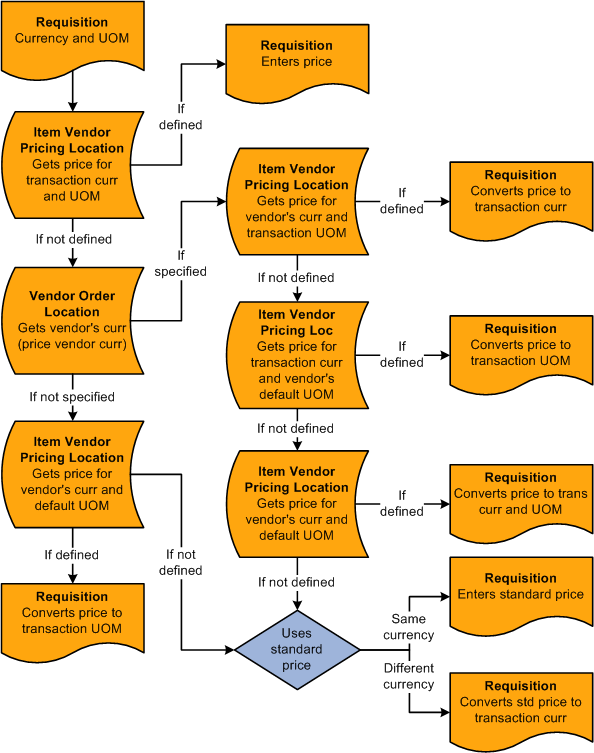

You can define multiple currencies and UOMs for a pricing location. When multicurrencies are involved, the system creates the requisition and purchase order provided that there is a currency and UOM match. If there is no match, the system uses an additional hierarchical path to determine the price and currency to use when creating the requisition and purchase order. When required, the system also performs multicurrency conversions.

This diagram illustrates the multicurrency conversion hierarchy:

Multicurrency conversion

Requisitions are created in the PeopleSoft Purchasing business unit currency when the Allow Multicurrency Reqs (allow multicurrency requisitions) check box is clear on the Purchasing Definition - Business Unit Options page. If the check box is selected, the requisition is created in the requester's currency.

When the system determines the pricing location and the pricing location is defined in the Item Vendor setup, the following text describes the steps that the system uses to determine what price to use based on the requisition (transaction) currency.

Use these steps to determine the requisition multicurrency price:

If the pricing location has a price defined in the requisition currency and UOM, this is the price that is used.

If there is no match in step 1, the system looks at the currency defined for the vendor order location.

If the vendor location currency (price vendor location) is not specified, the system moves on to step 4.

If the vendor location currency (price vendor currency) is specified, the system accesses the item-vendor pricing location to obtain the price for the vendor location currency (price vendor currency) and transaction UOM. If there is a match, the system takes that price and converts it to the transaction currency.

If there is no match in Step 3, the system uses the transaction currency and vendor default UOM to find a match in the pricing location.

If it finds a match, this price is used on the requisition. When there is no match and if the vendor location currency is not defined, the system skips step 5 and moves on to step 6.

If there is no match in step 4, the system uses the price vendor currency derived in step 2 and the default UOM when checking the pricing location.

If there is a match, it converts it to the transaction currency.

If there is no match in step 5, the system uses the standard price.

If the currency is different, it converts that price to the transaction currency.

The requisition base price is derived from the transaction price. If the transaction price is in a different currency, the system converts it into the base price currency.

If the Allow Multicurrency POs check box is selected on the Purchasing Definition - Business Unit Options page, purchase orders are always built in the vendor order location currency (price vendor currency). If the vendor location currency is not defined, or if the Allow Multicurrency POs check box is clear, the purchase order is built in the currency for the PeopleSoft Purchasing business unit.

When the Override Suggested Vendor check box is clear, the purchase order is built from the requisition, and if currencies are different, the system converts the requisition transaction price or currency to the purchase order currency. If the Override Suggested Vendor check box is selected, the system follows the same vendor location hierarchies described previously.

If the purchase order is built from a requisition and the Define PO option was selected during requisition selection, the purchase order is built in the vendor currency, or the modified currency, if it was modified during Define PO.

See Also

Creating PeopleSoft Purchasing Business Units

Understanding VAT Drivers, VAT Driver Keys, and the Defaulting Hierarchy

for VAT Defaults

Understanding VAT Drivers, VAT Driver Keys, and the Defaulting Hierarchy

for VAT Defaults

The following table lists the PeopleSoft Purchasing VAT drivers and associated VAT driver keys for the VAT Defaults component. The table also indicates which drivers control defaults for the Services VAT Treatment:

|

VAT Driver |

VAT Driver Keys |

PeopleSoft Application |

Country |

State |

Applicable to Regular VAT Defaults |

Applicable to Services VAT Treatment Defaults |

|

Item BU |

Item SetID Item ID Business Unit |

Purchasing |

Optional |

Optional |

Yes |

No |

|

Item |

Item SetID Item ID |

Purchasing, Payables |

Optional |

Optional |

Yes |

Yes |

|

Item Category |

Item SetID Category Code |

Purchasing |

Optional |

Optional |

Yes |

Yes |

|

Vendor Location |

Vendor SetID Vendor ID Vendor Location |

Purchasing, Payables |

Optional |

Optional |

Yes |

Yes |

|

Vendor |

Vendor SetID Vendor ID |

Purchasing, Payables |

Optional |

Optional |

Yes |

Yes |

|

PO Business Unit |

Business Unit |

Purchasing |

Optional |

Optional |

Yes |

No |

|

PO Options |

SetID Process Option ID |

Purchasing |

Optional |

Optional |

Yes |

Yes |

|

VAT Entity Registration |

VAT Entity Country |

All |

Required |

Optional |

Yes |

No |

|

VAT Country |

Country |

All |

Not applicable |

Optional |

Yes |

No |

|

Credit Card Provider |

Vendor SetID Credit Card Vendor |

Purchasing |

Optional |

Optional |

Yes |

No |

See Also