11 Working with Multilevel Master Schedules

This chapter contains the following topics:

11.1 Understanding Multilevel Master Schedules

Multilevel master schedules support assemble-to-order production and delivery.

You set up and generate multilevel master schedules to:

-

Define demand information on a family basis and make changes as needed.

-

Define planning bills to acquire the options and features that you expect to sell.

When several material purchasing options are available, the planners can make informed decisions within the available time frame. The system uses planning bills to notify planners when special attention is needed.

-

Update a product plan with a change in customer demand or design specifications.

-

Configure the schedule generation to include only the information that you require.

-

Explode planned orders down to component items.

11.2 Setting Up a Feature Planned Percentage

This section provides an overview of planning bills and discusses how to set up a feature planned percentage.

11.2.1 Understanding Planning Bills

Planning bills are groups of items in a bill of material format that reflect how an item is sold. Planning bills help you manage the acquisition of a variety of options and features that might be included in a saleable end item.

Planning bills enable you to configure a pseudo end item. For a pseudo item, you do not have to assign a unique part number or maintain a bill of material for every combination of options and features that might be included in the end product.

You define planning bills to acquire the options and features in the proportion that you expect to sell. A final assembly schedule coordinates the material selection and assembly after you order the product options.

11.2.1.1 Example: Automobile with Two Engine Options

A part number can be assigned to the engine feature for planning purposes. The two engine options cannot be assembled together, so the engine feature never actually exists in inventory. It is a pseudo item.

A stocking type of K identifies that the parent (automobile) is planned for in the same way as a kit. The feature item (engine) has a stocking type of 0 (phantom). Phantoms call for a special type of processing for which the leadtime is zero and the order policy is lot-for-lot.

The planner does not know which automobile will ship with which engine next month, but the ratio of engine types consumed is predictable. The planning bill of material identifies the percentages of each type of engine that you expect to ship.

By exploding this bill against the master schedule for the planning family of automobiles, the system can calculate the total requirements for each type of engine.

11.2.1.2 Example: Exploding Planned Orders

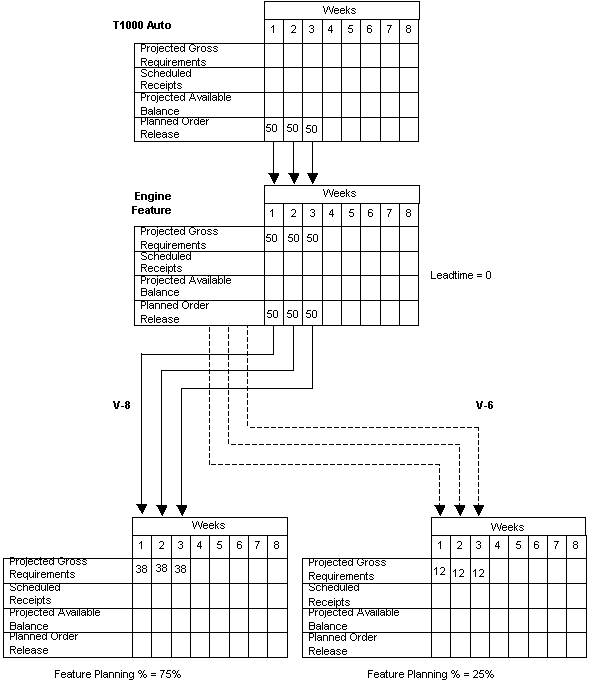

In this example, the system uses phantom processing to pass planned order releases from the parent (T1000 automobile) directly through to the planned order releases of the engine feature. The system uses the feature planning percentages to explode the planned order releases for the engine feature down to the gross requirements for V-8 and V-6 engines.

This diagram depicts how feature planned percentages are used to explode a planned order release down to gross requirements:

11.2.2 Form Used to Set Up Feature Planned Percentages

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| Enter Bill of Material Information | W3002A | Daily PDM Discrete (G3011), Enter/Change Bill

On the Work with Bill of Material form, find and select a bill of material or click Add. |

Set up a feature planned percentage.

Define the feature percentage for an item that is used for planning requirements. |

11.2.3 Setting Up a Feature Planned Percentage

Access the Enter Bill of Material Information form.

- Feat Plan % (feature planned percentage)

-

Enter the percentage of demand for a specified feature based on projected production. For example, a company might produce 65 percent of their lubricant with high viscosity, and 35 percent with low viscosity, based on customer demand.

Material Planning uses this percentage to accurately plan for a process's co-products and by-products.

Enter percentages as whole numbers, for example, enter 5 percent as 5.0. The default value is 100.00 percent.

11.3 Generating a Multilevel Master Schedule

This section provides an overview of multilevel master schedule generation and discusses how to run the MPS Regeneration for multilevel schedules.

11.3.1 Understanding Multilevel Master Schedule Generation

When you run the MPS - Gross Regeneration version of the MRP/MPS Requirements Planning program (R3482), the system compiles a master schedule. Select the MPS - Net Change version of the MRP/MPS Requirements Planning program when you want to include only those items that have changed since the last generation. You can create a version of the MRP/MPS Requirements Planning program specifically for multilevel master scheduling.

When you generate a multilevel master schedule, the system explodes planned orders to the bill of material component and identifies the percentages of all component items. By exploding the bill of material against the total number of expected sales of a parent item, you can obtain the total requirements for each item at each level in the bill of material.

When you generate a master schedule, the system evaluates selected information, performs calculations, and recommends a time-phased planning schedule for all selected items.