3 Entering Orders into Fulfillment Processing

This chapter contains the following topics:

-

Section 3.2, "Setting Up Sales Order Entry (P4210) to Process Fulfillment Orders"

-

Section 3.3, "Running the Fulfillment Entry Batch Processing Report (R4277704)"

3.1 Understanding Sales Order Processing with the JD Edwards EnterpriseOne Fulfillment Management System

This section discusses:

-

Fulfillment processing during sales order entry.

-

Fulfillment processing and JD Edwards EnterpriseOne Inventory Management.

-

Fulfillment processing and JD Edwards EnterpriseOne Demand Scheduling Execution.

-

Fulfillment processing and JD Edwards EnterpriseOne Transportation Management.

-

Fulfillment processing and JD Edwards EnterpriseOne Warehouse Management.

-

Fulfillment processing and Oracle Transportation Management.

3.1.1 Fulfillment Processing During Sales Order Entry

This section discusses how fulfillment processing works during sales order entry.

3.1.1.1 Order Activity Rules

The sales order statuses and order activity rules govern the processes that can be performed on sales order lines. You can set up a new status code in the order activity rules to represent the fulfillment processing step. The step should be after Enter Sales Order (520) and before Print Pickslips (540). If you use other processes between these two steps, such as approval processing or in warehouse, you must ensure the fulfillment step is sequenced appropriately.

Similar to the JD Edwards EnterpriseOne Sales Order Management programs, JD Edwards EnterpriseOne Fulfillment Management programs use processing options to increment status codes.

3.1.1.2 Commitment Processing (Release 9.1 Update)

The system does not check availability or soft commit inventory for sales order lines that enter the fulfillment process.

The JD Edwards EnterpriseOne Fulfillment Management system does not process hard committed lines. If you enter a location or lot number on a detail line during sales order entry, the system issues a hard error.

An order that goes into future commitment because it is outside of the commitment date window (from the branch plant constant settings) is called true future functionality or true future order commit. This distinction is necessary to differentiate between order quantity that goes onto future commitment because of the commitment date window and order quantity that goes onto future commit from advanced preference 41. The Fulfillment Management system is designed to take the place of the true future order system. In the event that a commitment date window and advance preference 41 are both active at order entry time, the system evaluates advanced preference 41 first, which takes precedence over any consideration of the commitment date window. You can simulate the commitment date window functionality within the Fulfillment Management system by using the requested date age scoring preference to create a score that is out of any range of consideration by the fulfillment processes until it comes within the specified commitment window. You run the Repost Active Sales Order report (R42995) to commit true future orders to current. After the orders are current, you run the Fulfillment Management Entry (R4277704) report to enter the orders into the Fulfillment Management system.

The system stores the order quantity in the Future Qty Committed field (SONE) for sales order lines that go into the fulfillment process. The quantity in the field is not considered a true future commitment. The system also enters a 1 into the In Fulfillment field (ALLOC) in the Sales Order Detail table (F4211), which indicates the order line is in the fulfillment process. When the order line enters the fulfillment process, the system moves the quantity from the Quantity Shipped field (SOQS) to the Future Qty Committed field; no quantities reside in the Quantity Backordered (SOBK) or Quantity Canceled (SOCN) fields. The system does not enable you to modify the quantities in these fields. The quantity on the sales order gets moved from the Future Qty Committed field to the Quantity Shipped field using the Auto Fulfillment Processing and the Fulfillment Workbench programs. The system does not allow the Repost Active Sales Orders report (R42995) to move fulfillment orders to soft commit.

3.1.1.3 Fulfillment Management Exclusions (Release 9.1 Update)

The JD Edwards EnterpriseOne Fulfillment Management system does not process these types of sales orders or line items:

-

Configured items and their components.

-

Non-stock items.

-

Blanket orders.

-

Quote orders.

-

Direct ship orders.

-

Credit orders.

-

Intercompany orders. The sales intercompany order type (SK) and the purchase intercompany order type (OK) are excluded. However the system does process interbranch sales order type (SI) through the Fulfillment Management system.

-

Future orders.

-

Orders entered in warehouse management processing.

-

Orders that are engineered to order.

-

Orders that generate a work order.

-

Orders that generate a purchase order. Transfer orders can enter fulfillment based on how you set up the Fulfillment Entry advanced preference.

-

Orders with quantities that have been relieved from on hand.

-

Orders with inventory quantities that are hard committed.

-

Backordered or canceled lines, either full or partial.

-

Kits with individually processed components

-

Order promising eligible order lines.

If the system determines that an order line is eligible to enter into the JD Edwards EnterpriseOne Fulfillment Management system, the system then validates the override next status that you set in the processing options. If the override next status is invalid, the system sets an error and does not accept the order line into the JD Edwards EnterpriseOne Fulfillment Management system. If the next status is valid, the system:

-

Updates the next status to the override next status.

-

Sets the In Fulfillment field to 1 in the F4211 to indicate the line is in the fulfillment process.

-

Sets the Fulfillment status to 10 (Entered).

-

Moves the shippable quantity from the Quantity Shipped field (SOQS) to the Future Quantity field (SONE).

-

Attaches service level rules per processing options.

-

Evaluates the inventory commitment preference.

-

Removes any prior fulfillment plan ID.

-

Balances dual quantities.

-

Scores the order if set in the processing options.

-

Populates the Customer Master Company field (CMCO) with the company from the customer master.

After you enter orders into the fulfillment process, the JD Edwards Fulfillment Management system permits you to revise sales order lines. You can:

-

Revise dates (only the Requested Date affects fulfillment).

-

Change branch/plant in the detail line.

-

Cancel lines.

-

Increase or decrease order quantities.

If you change the order quantity in a sales order line, the system must reevaluate the service level rule minimum fill percent for the line and order, and set the appropriate requirement met flags.

-

Replace or substitute an item.

-

Place an order on hold.

After you place an order on hold, the system ceases all fulfillment processing for that order until you release the order.

-

Override the service level rule information:

-

Override fill percentages for lines and orders.

-

Enter override reason codes.

-

Update the cancel flag.

-

-

Split lines.

When the system splits a line because of using the Release From Fulfillment report (R4277703), the system resolves service level rule information for the new line.

When the system splits a line outside of the fulfillment process (from pick slip, ship confirm, and so on), the system also copies the service level rule. You can then run the Fulfillment Entry Batch Processing report (R4277704) on the split line to enter the line into fulfillment processing and resolve a new service level rule if necessary.

When you make changes, the system revises the fulfillment state of the line and the quantity commitments as required. Depending on the changes that you make to the sales order lines, the system sets the evaluation required flag to indicate that the line and order fill percents should be reevaluated.

3.1.1.4 Fulfillment Batch Entry Processing

You can run the Fulfillment Entry Batch Processing report (R4277704) to enter open sales order lines into the fulfillment process. The system only evaluates order lines that are not currently in the fulfillment process. During the batch process, the system evaluates the Fulfillment Entry advanced preference for each order line based upon the data selection. The system sends an error message for any order line that it does not process. The error message indicates the reason for the system not accepting the order lines into the JD Edwards EnterpriseOne Fulfillment Management system.

3.1.2 Fulfillment Processing and JD Edwards EnterpriseOne Inventory Management

This section discusses how fulfillment processing works with:

-

Availability calculations.

-

Dual unit of measure items.

-

Future commitment orders.

-

Inventory commitment preference.

-

Kit items.

-

Order promising.

-

Partial shipments.

3.1.2.1 Availability Calculations

You define availability for each branch in the Branch/Plant Constants program (P41001). You decide what quantities are subtracted from and added to the on-hand quantity to calculate the available quantity. For the JD Edwards EnterpriseOne Fulfillment Management system, Oracle recommends that you:

-

Subtract the soft committed quantities. The system uses the available quantity to determine how much to fill inventory to sales order lines. As the Fulfillment Management system soft commits sales order lines; you must subtract soft commitments from the on hand balance to keep availability accurate.

-

Subtract the hard committed quantities. The system uses the available quantity to determine how much inventory to assign to sales order lines. If you do not use hard commitments in your system, it is not necessary to subtract hard commitments from the on hand balance.

-

Not subtract the future committed quantities. The system uses the available quantity to determine how much to fill inventory to sales order lines. The Fulfillment Management system puts the order quantity in the future committed bucket before processing the order. If you subtract future commitments from the on hand balance, you do not have accurate availability quantities during the fulfillment process.

-

Not subtract safety stock. When you use fulfillment rules to manage inventory levels with the Auto Fulfillment Processing report (R4277701), the system uses the rules to determine how much inventory to hold.

-

If you subtract safety stock from the on hand balance, you must set up a line with a value of zero in the Safety Stock Percentage field in the Fulfillment Rules Setup program (P4277720).

-

The chart on the Fulfillment Workbench program (P4277701) does not display the safety stock level if the quantity is subtracted from the on hand balance.

-

The Availability Checking field on the Item Master record (F4102) does not have any impact on items that go through the fulfillment process. The Auto Fulfillment Processing and the Fulfillment Workbench programs perform availability checking regardless of the setting in this field.

3.1.2.2 Dual Unit of Measure Items

The JD Edwards EnterpriseOne Fulfillment Management system processes orders with dual unit of measure (UOM) items with either the transaction UOM or the secondary UOM. The processed quantities are based on their conversions.

3.1.2.3 Inventory Commitment Preference

The JD Edwards EnterpriseOne Fulfillment Management system can process order lines that use the Inventory Commitment Preference. The system validates that the order line meets the specified percent to fill in the preference before releasing the order from fulfillment.

If the system is set up to perform fulfillment processing during order entry, the system uses a modified version of the Inventory Commitment Preference because the system does not check inventory availability. Therefore, the available inventory cannot determine the branch to be selected from the preference. The system cannot split lines based on the percent to fill for each of the branch/plant because inventory availability is not being checked. Also, instead of performing a hard commit to the sales detail, the system leaves the line as a soft commit and sets the indicator that the line is in the fulfillment process.

To use the modified version of the Inventory Commitment Preference, you must define only one line in the preference setup. The system uses the preference in the following way:

-

If the Percent to Fill field on the line equals zero, the system populates the branch/plant in the detail line of the sales order with the source branch from the preference. You can perform a first-pass fulfillment and assign the detail branch based on the preference; for example, the branch that is closest to the customer's ship-to location.

-

If the Business Unit field on the line is blank, the system stores the percent to fill value in the Sales Order Detail table (F4211) and validates this value during auto fulfillment processing, on the fulfillment workbench, and during release from fulfillment.

• If both the Business Unit and Percent to Fill fields are populated, the system populates the branch/plant on the detail line and stores the percent to fill value in the Sales Order Detail table and validates this value during auto fulfillment processing, on the fulfillment workbench, and during release from fulfillment.

If the preference is set up with multiple lines, the system does not store the percent to fill in the Sales Order Detail table. When this situation occurs, these conditions apply:

-

If the Percent to Fill field on the first line equals zero, the system populates the branch/plant in the detail line of the sales order with the source branch from the preference.

-

If the Percent to Fill field on the first line is greater than zero, the system does not use any of the preference information. The system is not checking availability and therefore cannot determine which line of the preference to apply.

When you run the Auto Fulfillment Processing report (R4277701), the system validates the fill percent and assigns inventory to meet the fill percent requirement. If the system cannot meet the fill percent requirement, it fulfils the line and sets a warning message. Use the Fulfillment Workbench program (P4277701) to change the fulfillment quantities and validate that each line meets the fill percent.

|

Note: The service level rule information takes precedence over the fill percent from the Inventory Commitment preference information.The system does not resolve the Inventory Commitment Preference for kit parent or component items. |

3.1.2.4 Kit Items

The JD Edwards EnterpriseOne Fulfillment Management system does not use the Auto Fulfillment Processing report to assign inventory to kits. However, you can use the Fulfillment Workbench program to interactively fulfill kit parent items. The system scores the parent and assigns this score to all of the kit components. When you locate and select a kit parent on the Fulfillment Workbench browse form, the system displays all components on the edit form and marks the components with a minus sign in the grid, thus disabling the component lines. The system also displays a notification when inventory is available for a component in another branch by placing a green check mark in the line.

You can use the Fulfillment Workbench program to perform these actions:

-

Change fulfillment quantity on kit parent. The system balances the filled quantities of the kit components based on the parent to child ratio and updates the components accordingly.

-

Change the promised delivery date of the parent.

-

View item availability for components when you click the grid line.

-

Access the Summary Availability (P41202) and Supply and Demand (P4021) programs for kit components.

You cannot change the branch plant for the parent or any component.

|

Note: The system only processes service level rules information against the kit parent item. |

3.1.2.5 Order Promising

When you create or modify sales order details, the Order Promising system calculates a promised date for the order by taking into account inventory levels of previously promised orders and other factors, which include:

-

Existing promised sales orders in the JD Edwards EnterpriseOne system.

-

The expectation of those orders being in a soft or hard commitment status.

-

Adhering to the promised dates for subsequent shipping.

The Fulfillment Management system manages the commitment statuses and subsequent promised dates for shipping and thus conflicts with the Order Promising system. Therefore, order lines that enter into the Fulfillment Management system cannot also be processed through Order Promising.

A sales order can include both Fulfillment Management items and Order Promising items.

3.1.2.6 Partial Shipments

Partial fulfillment of a sales order line can occur when you process orders from the following programs and reports:

-

Sales Order Entry (P4210).

-

Fulfillment Workbench (P4277701)

-

Auto Fulfillment Processing (R4277701)

When you partially fulfill an order line the system issues a warning to inform you that the Fulfillment Management system does not release order lines until the order or line percent is met; or the order line is completely fulfilled.

The system uses a soft warning instead of a hard error to enable it to maintain new and existing soft commitments. This action is critical because it allows the system to:

-

Temporarily hold inventory on an order until it can add more inventory.

-

Prevent lower priority orders from being fulfilled before orders with a higher priority.

The Release from Fulfillment report (R4277703) does not split partially fulfilled lines when:

-

The customer does not allow partial shipments.

-

The actual percent filled does not meet or exceed the percent to fill (resolved by the inventory commitment preference) or its service level fill percentages.

3.1.3 Fulfillment Processing and JD Edwards EnterpriseOne Demand Scheduling Execution

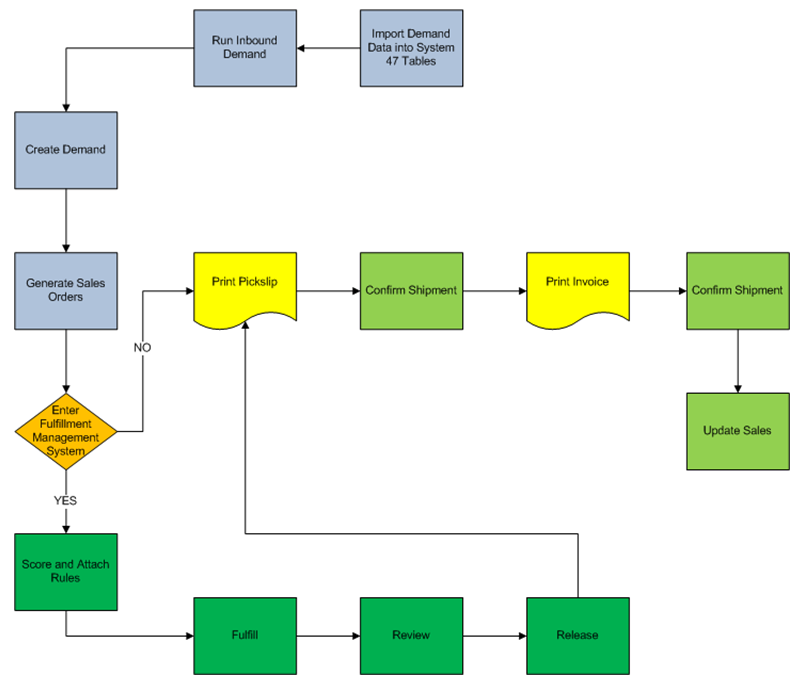

The JD Edwards EnterpriseOne Fulfillment Management system processes sales orders that are processed through the JD Edwards EnterpriseOne Demand Scheduling Execution system. This diagram illustrates the process:

Figure 3-1 Fulfillment processing and JD Edwards EnterpriseOne Demand Scheduling Execution

Description of "Figure 3-1 Fulfillment processing and JD Edwards EnterpriseOne Demand Scheduling Execution"

Typically, the sequence of events is:

-

Receive demand into the system 47 tables.

-

Run the EDI Inbound Demand Edit/Update report (R47171) to update the inbound demand.

-

Run the Create Demand Schedule report (R40R010) to generate sales orders.

The system enters orders into the Fulfillment Management system. You then perform the tasks within fulfillment to process the sales order lines.

-

Create shipments to meet the demand.

-

Create bills of lading for the orders.

-

Ship confirm the orders.

-

Adjust demand and populate the new cumulative shipped values into the Cum (cumulative) History tables.

3.1.4 Fulfillment Processing and JD Edwards EnterpriseOne Transportation Management (Release 9.1 Update)

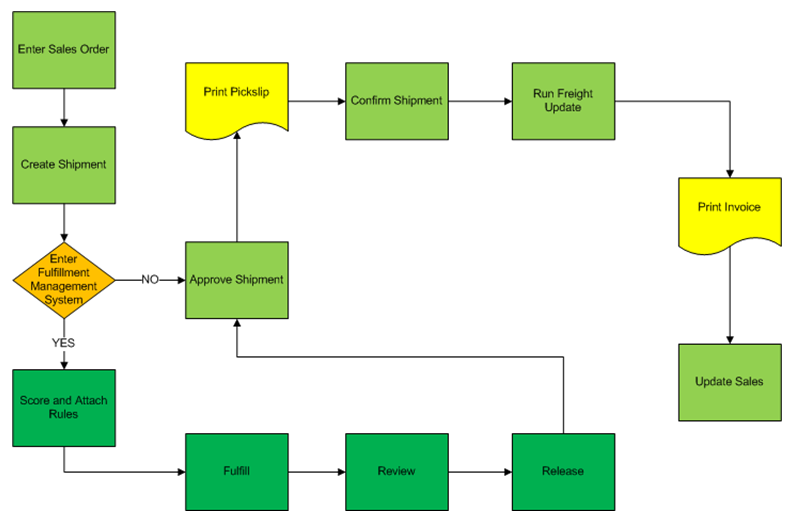

The JD Edwards EnterpriseOne Fulfillment Management system processes sales orders that are processed through the JD Edwards EnterpriseOne Transportation Management system. This diagram illustrates the process:

Figure 3-2 Fulfillment processing and JD Edwards EnterpriseOne Transportation Management

Description of "Figure 3-2 Fulfillment processing and JD Edwards EnterpriseOne Transportation Management"

Typically, the sequence of events is:

-

Enter sales order.

-

The Transportation Management system creates shipments.

-

The system determines whether to enter the sales order lines into fulfillment processing.

When order lines are released from fulfillment, the system adjusts the shipment quantities as appropriate to accommodate partial shipments.

-

Approve shipments.

-

Print pick slips.

-

Confirm shipments.

-

Run Freight Update.

-

Print invoices.

-

Update sales information.

When processing sales orders through the JD Edwards EnterpriseOne Transportation Management system, the system assigns shipment numbers to order lines at sales order entry. When the system does not allocate inventory to sales order lines, the unreleased sales order lines remain on the same shipment number as the released sales order lines. When this occurs, the system does not process shipments until all of the sales order lines have been released.

In order to not hold up shipments, you can activate the processing option in the Release from Fulfillment report (R4277703) to create a new shipment number for the sales order lines that remain in the fulfillment process. To ensure that shipment numbers are properly assigned to fully unreleased order lines, the Release from Fulfillment report runs a version of the Remove Unreleased Lines from Shipments report (R4277707).

See "Running the Remove Unreleased Lines from Shipments Report (R4277707) (Release 9.1 Update)"

The JD Edwards EnterpriseOne Transportation Management system assigns shipment numbers to order lines based on the shipment consolidation mode that you select. See Appendix B, "Scenarios for Shipment Consolidation Mode (Release 9.1 Update)"

3.1.5 Fulfillment Processing and JD Edwards EnterpriseOne Warehouse Management

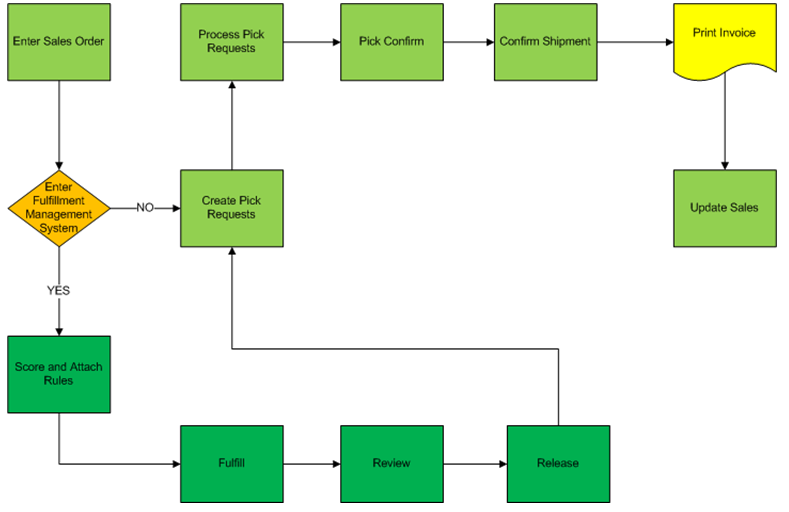

The JD Edwards EnterpriseOne Fulfillment Management system processes sales orders before the orders entering the JD Edwards EnterpriseOne Warehouse Management system. This diagram illustrates the process:

Figure 3-3 Fulfillment processing and JD Edwards EnterpriseOne Warehouse Management

Description of "Figure 3-3 Fulfillment processing and JD Edwards EnterpriseOne Warehouse Management"

Typically, the sequence of events is:

-

Enter sales order.

-

The system determines whether to enter the sales order lines into fulfillment processing.

-

After releasing order lines from fulfillment processing, the Warehouse Management system creates pick requests.

Note:

You must have the warehouse Request Processing Mode processing option set to blank on the Sales Order Entry program so that order lines do not enter into warehouse processing mode before fulfillment. -

Process pick requests.

-

Confirm picks.

-

Confirm shipments.

-

Print invoices.

-

Update sales information.

3.1.6 Fulfillment Processing and Oracle Transportation Management

The JD Edwards EnterpriseOne Fulfillment Management system processes sales orders that are processed through the Oracle Transportation Management integration processes:

-

The JD Edwards EnterpriseOne system enters the order into the fulfillment process.

-

The JD Edwards EnterpriseOne system processes and releases sales order lines from the fulfillment process.

-

The JD Edwards EnterpriseOne system transmits a freight request to the Oracle Transportation Management system.

-

The Oracle Transportation Management system transmits a transportation planning message to the JD Edwards EnterpriseOne system.

-

The JD Edwards EnterpriseOne system transmits a shipment confirmation message to the Oracle Transportation Management system.

-

The Oracle Transportation Management system transmits a transportation confirmation message to the JD Edwards EnterpriseOne system.

-

The JD Edwards EnterpriseOne system processes the sales order.

3.2 Setting Up Sales Order Entry (P4210) to Process Fulfillment Orders

This section discusses the forms and processing options for sales order entry.

See

3.2.1 Forms Used to Enter Sales Order Header and Detail Information

| Form Name | Form ID | Navigation | Usage |

|---|---|---|---|

| Work With Sales Order Headers | W4210H | Sales Order Processing (G4211), Enter Orders Header | Review and select sales order header records or access forms to add a new sales order. |

| Sales Order Header | W4210G | Click Add on the Work With Sales Order Headers form to add a new sales order.

Select a record on the Work With Sales Order Headers form, and click Select to revise an existing sales order. |

Enter sales order header information. |

| Sales Order Detail Revisions | W4210A | Click OK on the Sales Order Header form. | Enter sales order item information.

Enter default line information. Review secondary UOM and quantity information for the appropriate items. Override the default price and cost or change the values to zero. |

| Customer Service Inquiry | W4210E | Sales Order Processing (G4211), Sales Order Detail | Review and select sales order detail records. |

| Service Level Rules Inquiry/Override | W4277711A | Select a record on the Customer Service Inquiry form and click Select.

Select a record on the Sales Order Detail Revisions form. Select Service Level Rules from the Row menu. |

Review and override service level rules. |

3.2.2 Setting Processing Options for Sales Order Entry (P4210)

Use these processing options to process sales orders through the fulfillment process.

3.2.2.1 Commitment

- 1. Check Availability

-

Specify whether the system verifies the available quantity for requested items. Values are:

Blank: Bypass availability checking.

1: Activate, notify, and backorder or cancel.

2: Activate, notify, but do not backorder or cancel.

If you have fulfillment processing active during sales order entry, the system does not use this processing option. If all of your items enter the fulfillment process, you can leave this processing option blank.

The Auto Fulfillment Processing and the Fulfillment Workbench programs perform availability checking regardless of the setting in this processing option.

- 2. Commit to Quantity 1 or Quantity 2

-

Indicate the generic buckets to which the system commits quantities. Values are:

Blank: Do not commit quantities to buckets, Other Quantity 1 or 2.

1: Commit quantities to Quantity 1.

2: Commit quantities to Quantity 2.

Leave this processing option blank for Fulfillment Management. The Fulfillment Management system stores unfulfilled quantities in the future quantity bucket and fulfilled quantities in the soft commitment bucket.

- 4. Enter Allowed Lot Status Group to validate

-

Enter a lot group name to process lots whose lot status code is defined within the specified lot group name. The lot group name is a user defined list of allowed non-blank lot status codes.

The system uses the value in this processing option when sales order lines are processed through the Auto Fulfillment Processing report.

Note:

This option enables the system to increase availability for allowed lot statuses during auto fulfillment processing.

3.2.2.2 Versions

- 26. Fulfillment Management Scoring (R4277702)

-

Indicate which version of the Sales Order Score Batch Processing report (R4277702) the system runs to calculate the order score when you activate the Calculate Order Score processing option on the Fulfillment Management tab. If left blank, the system runs version XJDE0001.

- 28. Service Level Rules Processor (R4277705)

-

Indicate which version of the Service Level Rules Update report (R4277705) the system runs to resolve service level rules when you enter sales orders or change the branch/plant on a sales order line. You must activate the Resolve Service Level Rules processing option on the Fulfillment Management tab. If left blank, the system runs version XJDE0001.

3.2.2.3 Preference

- 2. Inventory Commitment Preference

-

Specify whether you want the inventory commitment preference to operate independently of other preference processing.

You use inventory commitment to specify that each order line be filled from one or more branch/plants based on customer, customer group, item, or item group. You can specify the branch/plants from which you want products shipped, determine the percentage of the order that must exist at a branch/plant before the quantity is filled at that branch/plant, or specify the mode of transportation and carrier information in the sales detail line. Values are:

Blank: The system does not use the inventory commitment preference.

1: Use inventory commitment preference processing only for current orders. The system performs inventory commitment preference only for those orders that are inside the commitment window of the header branch/plant. Orders that are outside the window of the header branch/plant are future committed to the header branch/plant.

2: Use inventory commitment preference processing for all orders. The system performs inventory commitment preference for all orders, regardless of the commitment window of the header branch/plant.

Note:

The system uses a modified version of the Inventory Commitment Preference for order lines that enter the fulfillment process during sales order entry. - 3. Override Schedule For Advanced Preferences

-

Use this processing option if you are using the Advanced Preferences function and want to specify an override preference schedule for the system to use instead of the default preference schedule that is defined in the system constants. If you are using Advanced Preferences, this schedule controls preference processing.

3.2.2.4 Warehouse

- 1. Request Processing Mode

-

Specify whether the system creates a pick request in the Warehouse Management system. Values are:

Blank: The system does not generate pick requests.

1: The system generates requests only.

2: The system generates requests and creates the pick request through the subsystem

Note:

Leave this processing option blank for Fulfillment Management. If a sales order enters warehouse, the lines are not eligible for fulfillment processing.

3.2.2.5 Audit Log

- 1. Use Audit Log for Sales Order Changes

-

Specify whether to activate the audit logging process for sales order changes. Values are:

Blank: Do not activate audit logging.

1: Activate audit logging.

Note:

You can override this processing option by using the Bypass Audit Logging field, which is in the Customer Billing Instructions. For example, if you set this processing option to1 and set the Bypass Audit Logging option for the customer specified in the sales order, then the system does not perform audit logging for any order for the specified customer.

Caution:

Fulfillment Management only supports blanks or option 1.If you activate this option and you are using the JD Edwards EnterpriseOne Fulfillment Management, audit logging functionality does not work with the Auto Fulfillment Processing (R4277701) and Fulfillment Entry (R4277704) reports. However, if you make changes by using the Fulfillment Workbench program (P4277701), the system creates an audit log in the Audit Log Transaction (F42420) table.

- 2. Reason Code required for Sales Order Changes

-

Specify whether a revision reason code is required for sales order changes. Values are:

Blank: Do not require a revision reason code.

1: Require a revision reason code.

- 3. Approval process required for Sales Order changes

-

Specify whether the approval process is required on the changes made to the sales order. The Use Audit Log for Sales Order Changes processing option on the Audit Log tab must be set to 1 to enable the approval process. However, you can enable audit logging without setting the Approval Process Required for Sales Order Changes processing option. When approval process is required, the system does not record changes to the order. Instead, the system retains the original values and places the order on hold. The new values are pending in the Audit Log table until an approval or rejection decision has been made. The new values are recorded for the order only if the order is approved. Values are:

Blank: The approval process is not required.

1: The approval process is required.

3.2.2.6 Order Promising

- 1. Order Promising

-

Specify the mode of order promising that the system uses to promise a delivery date for an order. Values are:

Blank: Do not use order promising.

1: Use the auto promising mode of order promising.

Note:

The system does not use this processing option for items that enter the fulfillment process. If all of your items enter the fulfillment process, you can leave this processing option blank.

3.2.2.7 Fulfillment Management

- 1. Calculate Order Score

-

Specify whether the system calculates the order score during sales order entry when the Fulfillment Management system is active. Values are:

Blank: No

1: Yes

- 2. Resolve Service Level Rules

-

Specify whether the system resolves service level rules during sales order entry when the Fulfillment Management system is active. Values are:

Blank: No

1: Yes

3.3 Running the Fulfillment Entry Batch Processing Report (R4277704)

This section discusses how to:

-

Run the Fulfillment Entry Batch Processing report.

-

Set processing options for Fulfillment Entry Batch Processing (R4277704).

3.3.1 Running the Fulfillment Entry Batch Processing Report

Select Fulfillment Management Advanced & Technical Ops (G4277730), Fulfillment Entry Batch Processing.

3.3.2 Setting Processing Options for Fulfillment Entry Batch Processing (R4277704)

These processing options control override processing and versions for the Fulfillment Entry Batch Processing report.

3.3.2.1 Process

- 1. Override Next Status

-

Indicate the next step in the order process. You must set up the user-defined code (40/AT) that you specify in the Order Activity Rules based on the order type and the line type that you are using.

The override status is another optional step in the fulfillment process. The combination of the beginning status and the override next status must be a valid last status/nest status combination in the Order Activity Rules table.