14 Return Outbound Inventory

This chapter contains the following topics:

14.1 Returning Outbound Inventory

When you ship consigned or vendor managed inventory to your customer's location, some inventory can get damaged or expired. When the customer wants to return damaged, expired or unused outbound inventory, they do so by creating a credit order. The credit order issues necessary credits to the supplier and makes adjustments for the returned outbound inventory.

You use the Sales Order Entry application to create credit orders to return outbound inventory. When you create a credit order to return outbound inventory, you must also associate the respective agreement information with it. Depending on the agreement type, and the processing option setup for the Sales Order Entry application (P4210), the system defaults the line type on the credit order.

When you create a credit order for an internally owned shipment order with a consigned inventory or internally owned VMI agreement attached to the order detail line, the system defaults the price on the order detail to zero, because an internally owned shipment order does not have any price attached to it.

You can enter the lot and serial numbers of the inventory that you return to the supplying location. After you confirm shipment of the credit order, the system updates the Outbound Inventory Item balance table (F42I021) and returns the inventory back to the supplying location. When the inventory is received at the supplying location, the system also increases the remaining quantity for the respective agreement.

14.2 Entering Credit Orders to Return Outbound Inventory

This section provides an overview of returning outbound inventory and discusses how to return outbound inventory to the supplying location.

14.2.1 Understanding Creating Credit Orders to Return Outbound Inventory

You enter a credit order manually to record a returned item and credit the current price to the customer. For internally owned shipments, the credit orders do not have a price attached. You use the credit order to update inventory balance information and agreement remaining quantity information. You enter credit orders in the same way that you enter sales orders.

When you confirm shipment of the credit order you create to return outbound inventory, the system reduces the quantity from the customer's location and increases the quantity at the supplying location. The system also increases the agreement remaining quantity when the returned inventory is received at the supplying location.

14.2.1.1 Create a Version for Credit Orders

Before you enter credit orders to return outbound inventory, you must create a version of the Sales Order Entry program (P4210) that is set up to process credit orders. The credit order version should have the Line Type processing option on the Defaults tab set to the line type that is set up for credit orders. Typically, this is line type C. You should also set the Order Type processing option on the Defaults tab to the order type to use for credit orders. Typically, this is CO. You must then attach this version to the menu option that you use to create credit orders. Contact the system administrator for assistance with this task.

14.2.2 Understanding Outbound Inventory Agreement Selection for Credit Orders

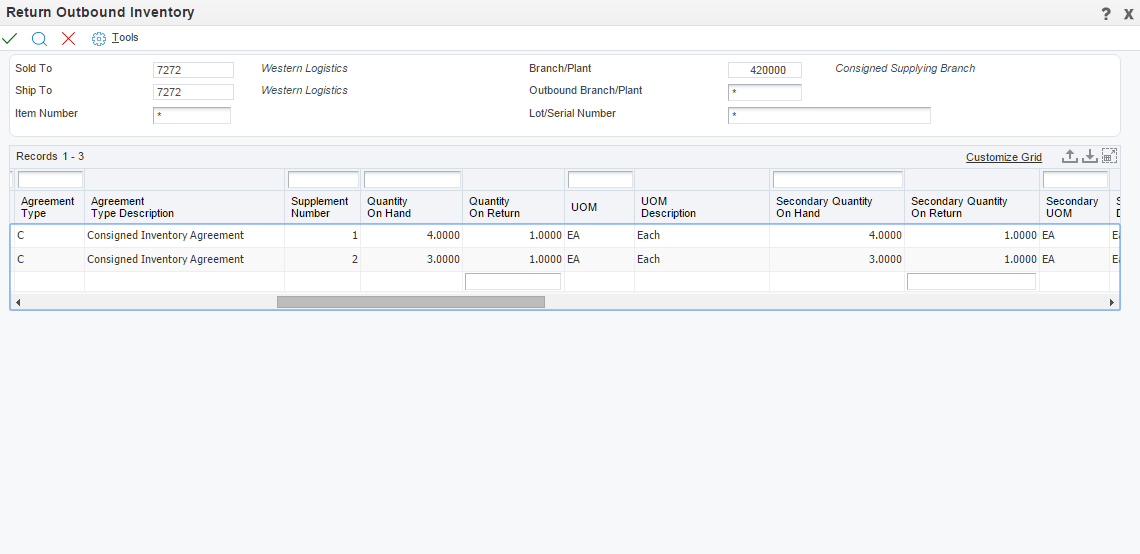

When you create credit orders to return outbound inventory, you must also attach the respective outbound inventory agreement to it. Depending on the processing option for the Sales Order Entry program (P4210), the system displays the Outbound Inventory Selection application with the following information:

-

Item number

-

Agreement number

-

Quantity on hand

-

Secondary quantity on hand

-

Outbound location type

|

Note: If you do not set up processing options for the Sales Order Entry program to process credit orders, the system does not display the above values in the Outbound Inventory Agreement Selection screen. |

14.2.3 Setting Processing Sales Order Entry program (P4210)

Processing options for the Sales Order Entry program control how outbound inventory agreements are attached to outbound inventory order detail lines.

14.2.3.1 1-Default

- Order Type

-

Use this processing option to identify the type of document.

To process credit orders, enter CO in this field.

- Line Type

-

Use this processing option to specify a code that controls how the system processes lines on a transaction.

14.2.3.2 29-Outbound Inventory

Use this processing option to specify how the system resolves the outbound inventory agreement.

To process credit orders, the system does not resolve outbound inventory agreements automatically. Even if you set the processing option to select agreements automatically, the system displays the Outbound Inventory Agreement Selection application.

You must select the agreement manually to attach to the credit order.

14.2.4 Creating Credit Orders

Access the Sales Order Entry Program.

| Form Name | Form ID | Navigation |

|---|---|---|

| Create Sales Order - Header First - Order Details Revisions | P42I01 | G4211, Create Sales Order - Detail First |

On the Sales Order Entry form, complete the following fields.

- Quantity Ordered

-

Enter the quantity of the item that you want to return to the supplying location.

- UOM (Unit of Measure)

-

Enter a code (00/UM) that indicates the transaction unit of measure for the outbound inventory credit order, for example, CS (case), EA (eaches) or BX (box). If you leave this field blank, the system populates the field using the default UOM value that you enter in the Item Master table (F4101).

- Item Number

-

Enter the alphanumeric identification number of the item that you want to return. The system populates many of the fields on each item line based on the information that is stored in the Item Master table for the item that you enter. The value that you enter can be in short, long, or third-item number format.

- Ln Ty (Line Type)

-

When you complete the outbound inventory agreement search criteria on the Order Header Revisions and Order Details Revisions applications (Sold To, Ship To, Branch/Plant, Order Quantity and Item Number), the system displays the Outbound Inventory Agreement Selection application. After you select the desired outbound inventory agreement, the system changes the line type to the one which is required for generating a credit order.

- Unit Price

-

Credit orders for internally owned shipment do not have any price attached.

For customer owned VMI orders, review the list or base price to be returned for one unit of this item that the system retrieves from the outbound inventory agreement. In Sales Order Entry, all prices must be set up in the Item Base Price File table (F4106). You can override the Unit Price.

- Lot Number

-

Enter a number that identifies a lot or a serial number for the item.

- Agreement Number

-

The system displays the agreement number of the outbound inventory agreement resolved for the search criteria that you enter.

If you know the correct outbound inventory agreement number, you can also enter it directly in this field.

|

Note: Alternately, you can select the Outbound Inventory Agreement Selection application directly from the Form menu on the Sales Order Entry application. You enter the required search criteria and select the agreements from the grid, to fetch the agreements for which you want to return inventory. You select all agreements for which you want to return inventory. The system populates all records in the Sales Order Entry application. You can then enter credit orders for all the agreements that you selected in the Outbound Inventory Agreement Selection application. |

14.2.5 Confirming Shipment for Credit Orders

When you confirm shipments for credit orders to return outbound inventory, the system reduces the on-hand inventory from the customer's location. When you receive the inventory at the supplying location, the system adds the quantity to the inventory at the supplying location and the agreement remaining quantity.

You confirm shipment for credit orders in the same way that you confirm shipments for other outbound inventory orders.

14.2.6 Running Sales Update Program for Outbound Inventory Credit Orders

When you run the Sales Update program for internally owned shipment credit orders, the system moves the inventory from the consigned inventory account to the inventory account. You can track the movement of inventory using the Internally Owned Shipment G batch.

14.3 Returning Outbound Inventory Through Return Material Authorization (RMA) (Release 9.1 Update)

This section provides an overview of Return Material Authorization (RMA) and discusses how to return outbound inventory using RMA.

14.3.1 Understanding RMA

An RMA is an authorization from the supplier to the customer for returning outbound inventory for credit, replacement or repair. When you create an RMA for outbound inventory, you can:

-

Create a purchase order to receive the inventory from the customer and a sales order to ship the replacement.

-

Create a purchase order to receive the inventory from the customer and a credit order to return the amount charged for inventory.

Worldwide Pharmaceuticals sells medicinal and surgical goods to International Hospitals on consignment. A surgical knife received at International hospitals, was found to be damaged during shipment. Since International Hospitals has not yet paid for the knife, there is no financial return. To update the inventory correctly and to track the returned goods, a purchase order is created to receive the goods at Worldwide Pharmaceuticals from International Hospitals. Also, a sales order is created to ship a replacement surgical knife from Worldwide Pharmaceuticals to International Hospitals.

If the payment for the knife is already complete, a purchase order is created to receive the surgical knife and a credit order is created to return the amount charged for the surgical knife.

14.3.2 Prerequisites

You must set up RMA default information before creating returns through the Return Material Authorization application.

14.3.3 Creating RMAs

This section provides an overview of RMAs, lists prerequisites, and discusses how to:

-

Set processing options for the Returned Material Authorization Revisions program (P400511).

-

Set processing options for the Work with Return Material Authorization program (P40051)

-

Enter Return Material Authorization

14.3.3.1 Understanding RMA Entry For Outbound Inventory

You create an RMA as an authorization from the supplier for the customer to return outbound inventory for credit or replacement. When you enter an RMA, the system creates an authorization number to track the return of inventory. You can use the RMA entry programs to:

-

Provide an authorization number for returning outbound inventory.

-

Create a purchase order to return the item to the customer.

-

Create a credit order to return the amount collected to the customer.

-

Create a sales order to send replacement inventory to the customer.

-

Associate the consigned or VMI order to the return.

When you enter an RMA, the system creates a record in the Return Material Authorization table (F40051) and Outbound Hold/Return Transactions table (F42I09). You can use the RMA applications to return both quantity-on-hand and quantity-on-hold.

14.3.3.2 Prerequisites

Before you complete the tasks in this section:

-

Define default values for creating sales and purchase orders.

-

Set up RMA status UDC (40/RN)

-

Set up a unique document type for RMA.

-

Set up a version of Sales Order Entry program (P4210) for credit orders.

-

Set up the Return Material Authorization Defaults program. In the P40052 program you can specify the versions of the P4210 program for sales orders and credit orders, and the version of Purchase Order Entry (P4310) to use for RMAs. If you leave the versions blank, the system uses version ZJDE0001.

14.3.3.3 Setting Processing Options for the Return Material Authorization Revisions Program (P400511)

Use these processing options to set system default values, control which fields are edited, control system processing, and specify versions.

14.3.3.3.1 Defaults

These processing options control the default information that the system uses when working with RMA revisions.

- 1. Default RMA document type

-

Enter a value from user-defined code (UDC) 00/DT for the default RMA document type, for example, R8 or R9.

- 2. Work Order Number to the Sales Order Subledger field

-

Specify whether the system enters the work order number in the Sales Order Subledger field. Values are:

Blank: The system does not enter the work order number in the sales order subledger field.

1: The system enters the work order number in Sales Order Subledger field.

- 3. Inventory Item Number from the Service Work Order

-

Specify whether the system enters the item number into the RMA when receiving parts. Values are:

Blank: The system does not enter the item number in the receipt.

1: The system enters the inventory item number for receipt from the service work order header.

- 4. Inventory Item Number for Shipment from the Service Work Order

-

Specify whether the system enters the item number into the RMA when shipping parts. Values are:

Blank: Do not enter the item number in the shipping document.

1: Enter the inventory item number for shipment from the service work order header.

- 5. Equipment Number for Receipt from the Service Work Order

-

Specify whether the system enters the equipment serial number into the RMA when you receive parts. Values are:

Blank: Do not enter the serial number.

1: Enter the serial number.

- 6. Equipment Number for Shipment from the Service Work Order

-

Specify whether the system enters the equipment serial number into the RMA when you ship parts. Values are:

Blank: Do not enter the serial number.

1: Enter the serial number into the RMA when you ship parts.

- 7. Last Disposition For Credit Memo

-

Specify the line type of the RMA detail line when the RMA is created from the sales ledger and the RMA creates a credit memo. Enter a value from UDC 40/RN.

- 8. Last Disposition for Warranty Claim

-

Specify a value from UDC 40/RN that indicates the line type to be used to create the RMA detail line when you create the RMA from a warranty claim.

- 9. Last Disposition for Supplier Recovery Claim

-

Specify a value from UDC 40/RN that indicates the line type to be used to create the RMA detail line when you create the RMA from a supplier recovery claim.

14.3.3.3.2 Edits

These processing options control which fields are required when you enter an RMA.

- 1. Work Order Number Required

-

Specify whether the system requires a work order number when you enter an RMA. Values are:

Blank: Work order number is not required.

1: Work order number is required.

- 2. Request Number Required

-

Specify whether the system requires a request number when you enter an RMA. Values are:

Blank: Request number is not required.

1: Request number is required.

- 3. Original Sales Order Number Required

-

Specify whether the system requires the original sales order number when you enter an RMA. Values are:

Blank: Original sales order number is not required.

1: Original sales order number is required.

- 4. Original Invoice Number Required

-

Specify whether the system requires the original invoice number when you enter an RMA. Values are:

Blank: Original invoice number is not required.

1: Original invoice number is required.

- 5. Reason Code Required

-

Specify whether the system requires a reason code when you enter an RMA.

Blank: Reason code is not required.

1: Reason code is required when the RMA is created.

2: Reason code is required when the disposition is attached.

14.3.3.3.3 Process

These processing options control whether the system sends a message of the goods that are expected to be returned and whether the Parts List Search & Select field is displayed in add mode.

- 1. Send message of the goods expected to be returned

-

Specify whether the system sends a message of the goods expected to be returned. Values are:

Blank: Do not send a message.

1: Do send a message.

- 2. Display 'Parts List Search & Select' in Add Mode

-

Specify whether the system displays the parts list search and select in add mode. Values are:

Blank: Do not display parts list search and select in add mode.

1: Display parts list search and select in add mode.

14.3.3.3.4 Versions

These processing options control the versions that are called by the program.

- 1. Sales Ledger Inquiry (P42025)

-

Enter a version of the Sales Ledger Inquiry program (P42025) that is set up for credit memos. If you leave this field blank, the system uses version ZJDE0001.

- 2. Quick Customer Add (P01015)

-

Enter a version of the Quick Customer Add program (P01015) that the system uses to add a new customer record. If you leave this field blank, the system uses version ZJDE0001.

- 3. Work With Work Orders (P48201)

-

Enter a version of the Work With Work Orders program (P48201). If you leave this field blank, the system uses version ZJDE0002.

- 4. Work With Maintenance Request (P17500)

-

Enter a version of the Work With Maintenance Request program (P17500). If you leave this field blank, the system uses version ZJDE0001.

- 5. OnLine Invoice Inquiry (P42230)

-

Enter a version of the OnLine Invoice Inquiry program (P42230). If you leave this field blank, the system uses version ZJDE0001.

- 6. Shipment Confirmation (P4205)

-

Enter a version of the Shipment Confirmation program (P4205). If you leave this field blank, the system uses version ZJDE0001.

- 7. Purchase Receipts Inquiry (P43214)

-

Enter a version of the Purchase Receipts Inquiry program (P43214). If you leave this field blank, the system uses version ZJDE0001.

- 8. Item Availability (P41202)

-

Enter a version of the Item Availability program (P41202). If you leave this field blank, the system uses version ZJDE0001.

- 9. Item Cross Reference (P4104)

-

Enter the version of the Item Cross Reference program (P4104). If you leave this field blank, the system uses version ZJDE0001.

- 10. Purchase Order Receipt Entry (P4312)

-

Enter the version of the Purchase Order Receipt Entry program (P4312). If you leave this field blank, the system uses version ZJDE0001.

- 11. Open Order Inquiry (P4310)

-

Enter the version of the Open Order Inquiry program (P4310). If you leave this field blank, the system uses version ZJDE0001.

14.3.3.4 Setting Processing Options for the Work with Return Material Authorization Program (P40051)

Use the processing options to set system default values and specify versions.

14.3.3.4.1 Default

These processing options control default information that the system provides when you are entering RMA information.

- 1. RMA Document Type

-

Specify a value from UDC 00/DT that indicates the document type of the RMA records to be created.

- 2. Header Branch/Plant

-

Specify a default branch/plant. Values are:

Blank: Use the branch/plant from the user location.

1: Use the branch/plant from the ship-to address.

2: Use the branch/plant from the sold-to address.

- 3. Default Branch/Plant

-

Specify a default branch/plant to use when you create RMA records. You can use existing branch/plant values for data entry purposes.

14.3.3.4.2 Versions

Use these processing options to control the versions of various programs that the system uses.

- 1. RMA Revisions - P400511 (ZJDE0001)

-

Specify the version of the Return Material Authorization Revisions program (P400511) that the system uses to enter RMA information. If you leave this processing option blank, the system uses the ZJDE0001 version.

- 2. Shipment Confirmation - P4205 (ZJDE0001)

-

Specify the version of the Shipment Confirmation program (P4205) that the system uses to confirm a shipment for sales orders that are created from the RMA. If you leave this processing option blank, the system uses the ZJDE0001 version.

- 3. Receipt Entry - P4312 (ZJDE0001)

-

Specify the version of the PO Receipts program (P4312) that the system uses to enter a receipt. If you leave this processing option blank, the system uses the ZJDE0001 version.

- 4. SO Entry - P4210 (ZJDE0001)

-

Specify the version of the Sales Order Entry program (P4210) that the system uses to access the Work with Return Material Authorization program (P40051). If you leave this processing option blank, the system uses the ZJDE0001 version.

- 5. PO Entry - P4310 (ZJDE0001)

-

Specify the version of the Purchase Order Entry program (P4310) that the system uses to access the P4310 program from the Work with Return Material Authorization program (P40051). If you leave this processing option blank, the system uses the ZJDE0001 version.

- 6. Work Order Revisions - P17714 (ZJDE0001)

-

Specify the version of the Work Order Revisions program (P17714) that the system uses to create a work order. If you leave this processing option blank, the system uses the ZJDE0001 version.

- 7. On-Line Invoice - P42230 (ZJDE0001)

-

Specify the version of the Online Invoice Inquiry program (P42230) that the system uses to create an invoice for sales orders that are created through RMAs. If you leave this processing option blank, the system uses the ZJDE0001 version.

- 8. Purchase Receipts Inquiry - P43214 (ZJDE0001)

-

Specify the version of the Purchase Receipts Inquiry program (P43214) that the system uses to locate purchase orders that are created through RMA. If you leave this processing option blank, the system uses the ZJDE0001 version.

- 9. PO Receipts - P4312 (ZJDE0001)

-

Specify the version of the PO Receipts program (P4312) that the system uses to enter a purchase order receipt. If you leave this processing option blank, the system uses the ZJDE0001 version.

- 10. Work With Work Orders - P48201 (ZJDE0002)

-

Specify the version of the Work With Work Orders program (P48201) that the system uses to find or add a work order. If you leave this processing option blank, the system uses the ZJDE0002 version.

- 11. Work With Maintenance Request - P17500 (ZJDE0001)

-

Specify the version of the Work With Case program (P17500) that the system uses to locate the request number that is related to an RMA. If you leave this processing option blank, the system uses ZJDE0001.

- 12. Work With Equipment Master - P1701 (ZJDE0001)

-

Specify the version of the Work with Equipment Master program (P1701) that the system uses to add or locate an equipment master record. If you leave this processing option blank, the system uses the ZJDE0001 version.

- 13. Print Pick Slips - R42520 (XJDE0001)

-

Specify the version of the Print Pick Slips program (R42520) that the system uses to process pick slips for sales orders that are created using RMA. If you leave this processing option blank, the system uses the XJDE0001 version.

14.3.3.5 Entering Return Material Authorizations

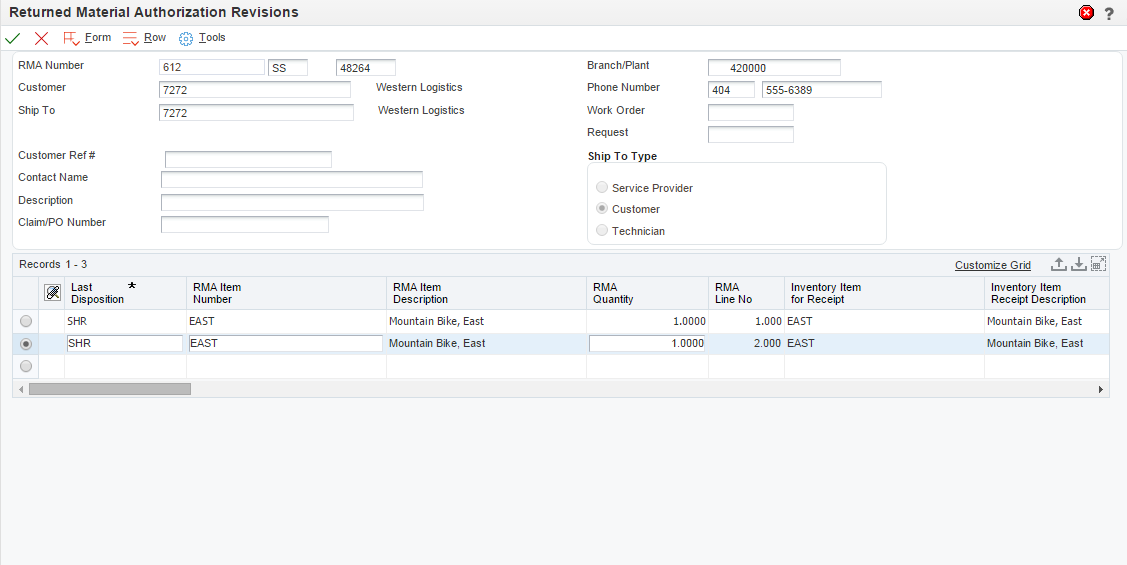

To return outbound inventory using RMA, use the Return Outbound Inventory application (P42I01). You search for items using Sold To, Ship To, Item Number, Outbound Branch/Plant and Lot. The system then displays the list of items that are available for return. You can return both quantity-on-hand and quantity-on-hold. The system also enables you to enter quantity-to-return in both primary and secondary units.

You access the Return Outbound Inventory application from the Form menu on the Returned Material Authorization Revisions application. After you complete the fields on the Return Outbound Inventory application, the system redirects you to the Returned Material Authorizations Revisions application and populates the values you entered in the Return Outbound Inventory application.

For returning outbound inventory transactions, you can use the following processes to create RMAs:

-

Create a credit order

-

Create a credit order and purchase order

-

Create a purchase order

-

Create sales order with zero price

-

Create sales order with zero price and a purchase order

-

Create a sales order with price

-

Create a sales order with price and a purchase order

Access the Returned Outbound Inventory program.

| Form Name | Form ID | Navigation |

|---|---|---|

| Returned Material Authorization Revisions | W400511E | Daily Work Order Processing (G1712) or Additional Order Processes (G4212), Returned Materials AuthorizationClick Add on the Work with Return Material Authorization form.

Select Outbound Inventory from the Form menu. |

On the Return Outbound Inventory form, complete the following fields to filter records:

- Item Number

-

Enter the item number of the item you want to return.

- Outbound Branch/Plant

-

Enter the outbound branch/plant where the inventory was originally shipped.

- Lot/Serial

-

Enter the lot number for the items you want to return.

Click the Find button. The system displays the following information based on your search criteria:

-

Item number and description

-

Outbound item group and description

-

Agreement information

-

Quantity on-hand and on-hold

-

Outbound location and outbound location type

After filtering records, complete the following fields in the grid on the Return Outbound Inventory form:

- Quantity On Return

-

Enter the on-hand quantity you want to return. This quantity is expressed in the primary unit of measure.

- Secondary Quantity On Return

-

Enter the on-hand quantity you want to return. This quantity is measured in the secondary unit of measure.

- Shipping Branch/Plant

-

Enter the branch/plant from where the item will be shipped.

After completing the fields, click the OK button. The system displays the Returned Material Authorization Revisions form.

On the Returned Material Authorization Revisions form, verify or complete the following fields:

- Customer

-

Verify the customer number for creating the RMA.

- Customer Ref # (customer reference number)

-

Use to cross-reference a customer number with the RMA.

- Branch/Plant

-

Enter the branch/plant that the system uses when creating the sales order and purchase order.

- Last Disposition

-

Enter a value from UDC 40/RN that indicates the current status of a Returned Material Authorization line. The special handling code for the Last Disposition field determines whether a purchase order, sales order (or credit order), or both are created when you enter the last disposition on an RMA line.

The special handling codes are:

1: Purchase order only.

2: Sales order only.

5: Purchase order and sales order.

7: Purchase order and credit order.

- RMA Item Number

-

Verify the item number for the item to be returned.

- RMA Quantity

-

Verify the quantity that you enter through the Return Outbound Inventory application.

- RMA Type

-

Enter a value from UDC 00/DT that indicates the document type of the RMA records.

14.3.3.6 Information Structure - Outbound Inventory and RMA

When you enter an RMA to return outbound inventory, the system updates the following tables with RAM information:

| Table | Information Updated |

|---|---|

| F42I09 |

|

| F40051 |

|