| Skip Navigation Links | |

| Exit Print View | |

|

Sun Storage 6 Gb SAS REM RAID HBA Installation Guide For HBA Models SGX-SAS6-R-REM-Z and SG-SAS6-R-REM-Z |

| Skip Navigation Links | |

| Exit Print View | |

|

Sun Storage 6 Gb SAS REM RAID HBA Installation Guide For HBA Models SGX-SAS6-R-REM-Z and SG-SAS6-R-REM-Z |

Chapter 2 Hardware Installation and Removal

Chapter 3 Creating a Bootable Drive in a Preboot Environment

Chapter 4 HBA Software Installation

This appendix contains the specifications for the HBA.

This appendix contains the following topics:

The HBA card size is as follows:

Height: 94.31mm (2.731 inches)

Length: 167.64mm (6.6 inches)

The HBA hard disk drive (HDD) interface through a 210-pin mezzanine plug provides links for up to eight HDD ports.

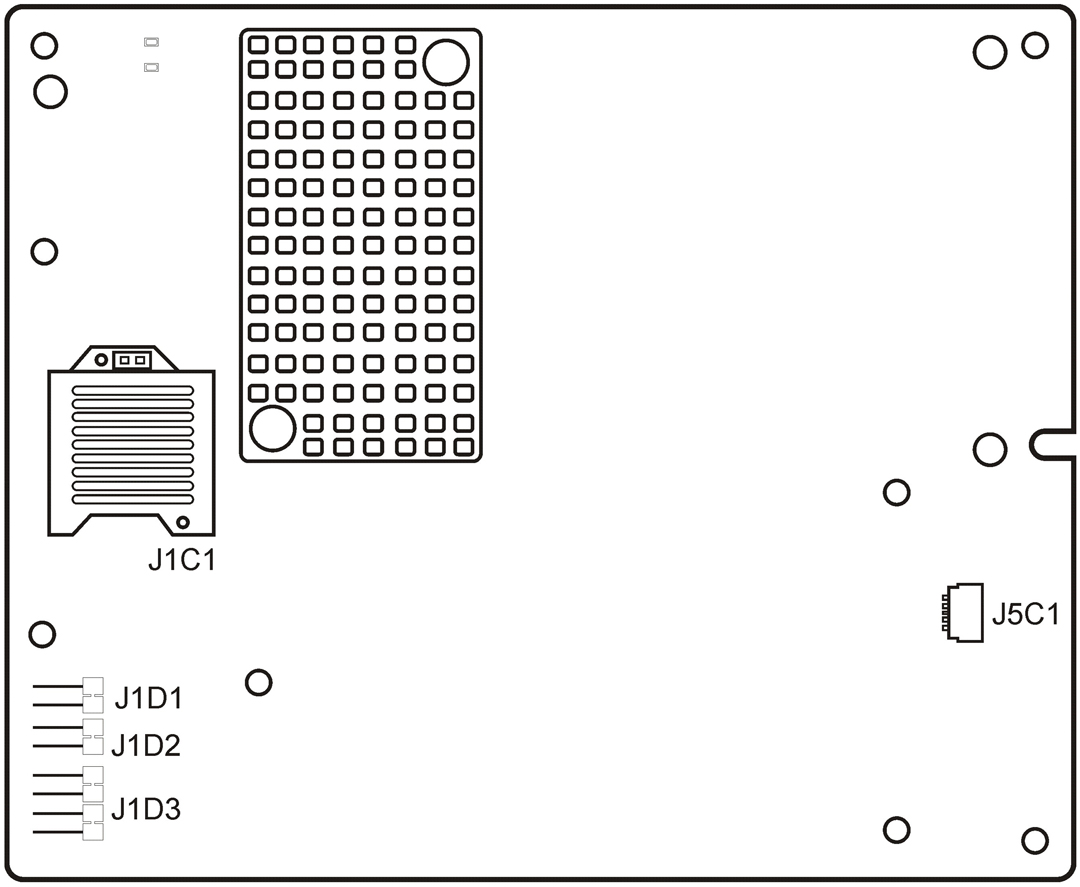

Card Layout of the HBA shows the jumpers and connectors on the HBA.

Figure A-1 Card Layout of the HBA

HBA Jumpers and Connectors describes the jumpers and the connectors on the HBA.

|

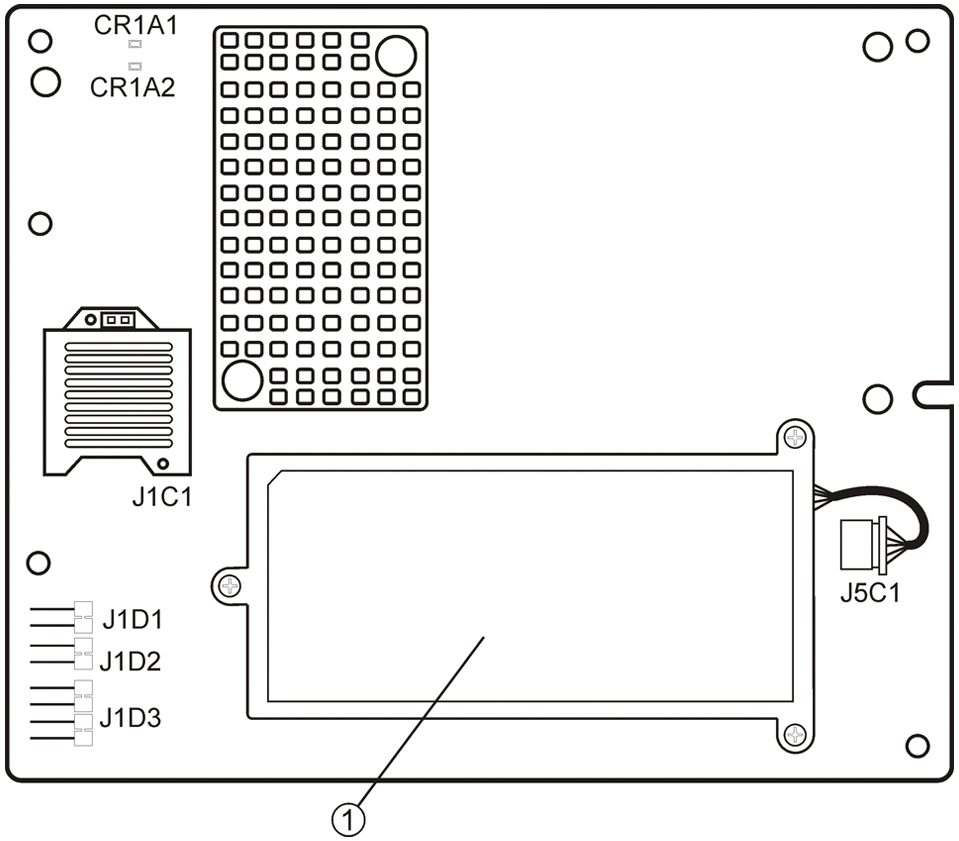

Intelligent Battery Backup Unit 08 (LSIiBBU08) on the HBA shows the HBA with the LSI intelligent Battery Backup Unit 08 (LSIiBBU08) installed.

Figure A-2 Intelligent Battery Backup Unit 08 (LSIiBBU08) on the HBA

Figure Legend

1 LSIiBBU08 - LSI Intelligent Battery Backup Unit 08

The HBA environmental requirements are listed in HBA Environmental Specifications.

|

Fault Tolerance Features lists the fault tolerance features for the HBA.

|

All power is supplied to the HBA through the PCI Express 3.3V rails and the 12V rail. Onboard switching regulator circuitry operating from the 3.3V rails and the 12V rail provide the necessary voltages. The following states determine the typical current consumption of the controller:

State 1: During a hard reset

State 2: During a disk stress test

State 3: While sitting idle at the DOS prompt

The supply voltages are 12V 8 percent (from PCI edge connector only) and 3.3V 9 percent (from PCI edge connector only). Power Supply for the HBA lists the power supply information for the controller for each of the three states at the different voltages.

|

+12V is used in the charging circuitry for the battery pack on the optional iBBU battery-backed daughter card. If the iBBU daughter card is mounted, the following power consumption figures apply: During fast charging of the battery pack: 230mA in +12V current