| C H A P T E R 1 |

|

Getting Started |

This chapter provides information and procedures needed to install and make the Sun Netra CP3000 AMC.1-HDD SAS disk operational. This chapter should be read before unpacking and installing the AMC.

In addition to this chapter, refer to the following safety document:

Important Safety Information for Sun Hardware Systems (816-7190)

|

Caution - When the system is plugged in, energy hazards are present on the midplane. Do not reach into the enclosure while the power is on. |

|

Caution - Static electricity can damage electronic components. Wear a wrist strap grounded through one of the system’s ESD ground jacks when removing and replacing hot-swappable components. |

This chapter contains the following topics:

The following sections briefly describe the minimum system requirements and the configurable features. Links are provided to other chapters and appendixes containing more detailed information.

The following operating systems are compatible with the AMC.1-HDD SAS disk.

Before using this AMC.1-HDD SAS disk, review the specifications of the chassis and backplane that will house the module to determine the presence of, and any limitations of, chassis, IPMI bus, and user-defined pin-outs. For example, some chassis backplanes route certain I/O pins to internal resources such as alarm cards and drive resources. The AMC.1-HDD SAS disk is intended for an AdvancedTCA AMC carrier card site that is AMC.1 compliant. It is your responsibility to verify system compatibility. Failure to do so could result in improper operation or equipment damage.

The AMC.1-HDD SAS disk modules plug into ATCA carrier boards that support a combination of AMC.1 (PCI Express) and AMC.3 (SAS) storage signaling.

At the time of publication of this document, the AMC.1-HDD SAS disk is qualified and supported on the following Sun blade servers:

See Appendix B for electrical and environmental requirements.

Check the shipping carton for damage. If the shipping carton or contents are damaged, notify the carrier and Sun. Retain the shipping carton and packing material for inspection by the carrier. Obtain authorization before returning any product to Sun. Refer to the Netra CP3000 Advanced Mezzanine Card PCIe SAS Controller and Hard Drive Getting Started Guide (820-7177) for return instructions.

|

Caution - The system is sensitive to static electricity. To prevent damage to the assembly, always connect an antistatic wrist strap between you and the system. |

Avoid touching areas of integrated circuitry. Static discharge can damage these circuits.

An antistatic wrist strap and a conductive foam pad is strongly recommend for handling AMCs when installing or upgrading a system. Electronic components, such as disk drives, computer boards, and memory modules can be extremely sensitive to electrostatic discharge (ESD). After removing the component from its protective wrapper or from the system, place the component flat on a grounded, static-free surface (and, in the case of a board, component side up). Do not slide the component over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by wearing an antistatic wrist strap (available in the shipkit and at electronics stores) that is attached to an active electrical ground. Note that a system chassis might not be grounded if it is unplugged.

|

Caution - Dangerous voltages, capable of causing injury or death, are present in this equipment. Use extreme caution when handling, testing, and adjusting within a system. |

|

Caution - Do not flex the AMCs; the surface-mounted components can break if the AMC is bent. |

Our suppliers take significant steps to ensure that there are no bent pins on the backplane or connector damage to the AMCs prior to leaving the factory. Bent pins caused by improper installation or by AMCs with damaged connectors could void the warranty for the backplane or boards.

To minimize the amount of AMC flexing, observe the following precautions:

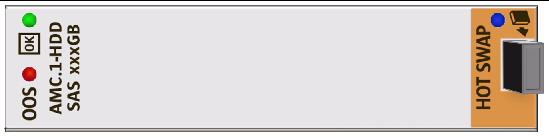

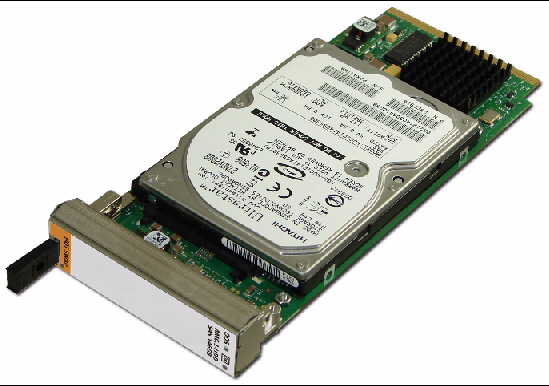

The following shows the faceplate of the Sun Netra CP3000 AMC.1-HDD SAS disk.

FIGURE 1-1 AMC.1-HDD SAS Disk Faceplate

| Note - The AMC is available in different capacities (in gigabytes). The illustration shows a generic faceplate. For your product’s faceplate, the xxx denotes the capacity. |

The following tables give status information for all of the LEDs on the AMC.

TABLE 1-1 describes the LEDs defined by ATCA to monitor board status.

|

Management power is available to the AMC, and the AMC can safely be extracted. |

|||

TABLE 1-2 describes in detail the different hot-swap BLUE LED states.

| Note - An AMC should be hot-swapped only when the LED is solid blue. |

This section describes how to remove and install AMCs.

The AMC.1-HDD SAS disk can be installed into an ATCA shelf (chassis) with sites that support AMC.1 PCI Express signaling. The site height must properly match the panel height fitted to the AMC.

At the time of publication of this document, the AMC.1-HDD SAS disk is qualified and supported on the following Sun blade servers:

If you want to remove only an AMC from a blade server, use the following instructions.

If you want to remove the blade server with the AMC installed, see the next section Section 1.6.2, Removing a Blade Server and AMC.

|

Caution - Before removing an AMC, read all cautions, warnings, and instructions presented earlier in this chapter. |

Removing a board before powering down the operating system might cause an OS panic, which could corrupt data or file systems.

2. At the front of the blade server, locate the AMC you want to remove.

Depending on the blade server’s AMC site location, you might have to remove the blade server from the chassis. Some blade servers have compartments for AMCs that can only be accessed when the blade server is removed from the chassis.

3. If the blade server must be removed to access the AMC, go to Section 1.6.2, Removing a Blade Server and AMC.

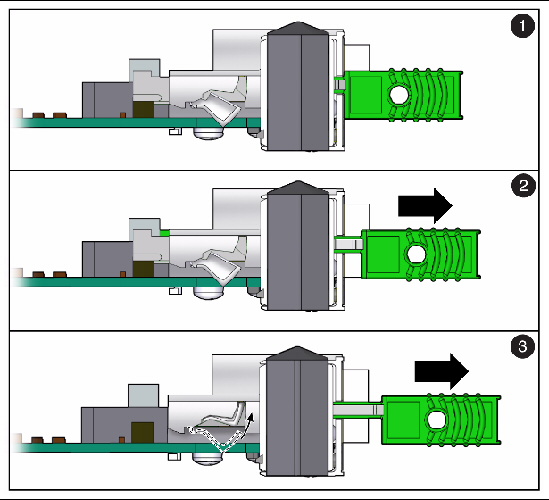

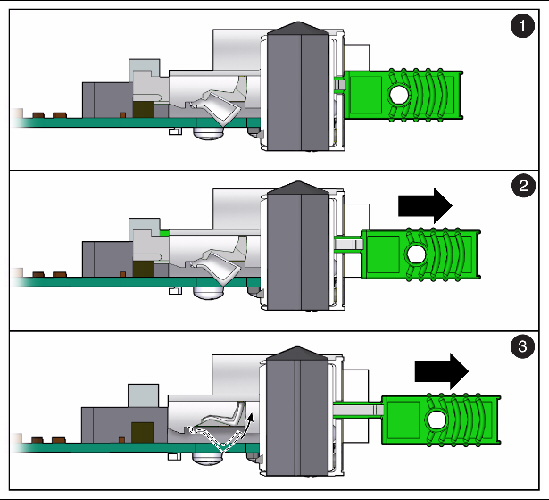

4. For the AMC, initiate the hot-swap deactivation sequence by pulling the injector/ejector latch out half way (FIGURE 1-2).

The Hot-Swap LED starts blinking.

5. Wait until the Hot-Swap LED is solid blue.

6. When the Hot-Swap LED is solid blue, pull the injector/ejector latch out completely (FIGURE 1-2).

FIGURE 1-2 Deactivating the AMC

8. Replace the AMC with another AMC (FIGURE 1-7) or install a filler panel.

| Note - Be sure to follow handling instructions. See Section 1.3, Handling AMCs. |

|

Caution - Failure to fill all slots with AMCs or cover with filler panels can negatively impact the cooling of the system. |

Following are the instructions for removing a blade server and installed AMC. For additional information, refer to your blade server documentation.

|

Caution - Before removing a blade server and AMC, read all cautions, warnings, and instructions presented earlier in this chapter. |

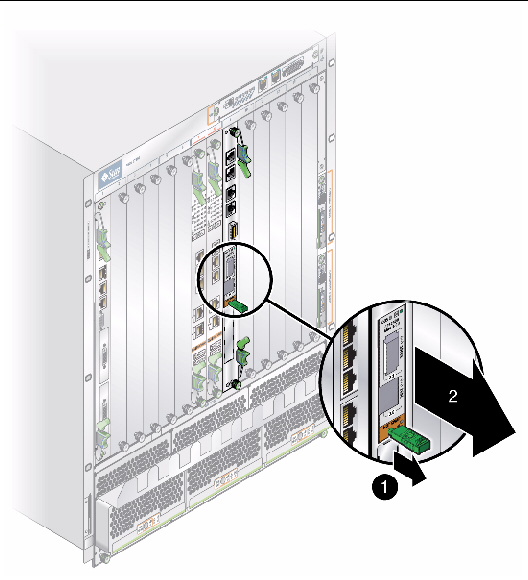

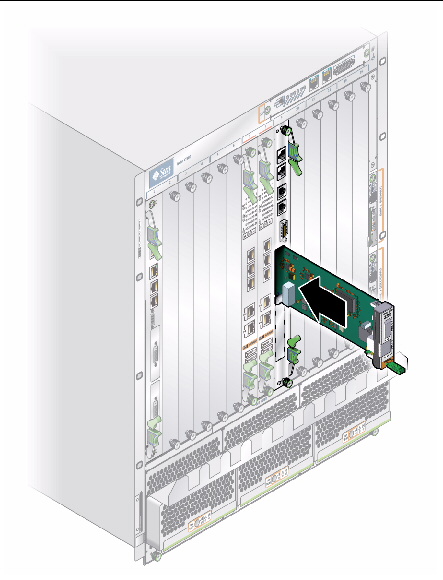

1. Move the front cable management bracket to the lower position (FIGURE 1-4).

FIGURE 1-4 Front Cable Management Bracket in Lower Position

2. Disengage the injector/ejector mechanisms at the top and bottom of the blade server to notify software that the board is about to be removed. Wait for the Hot-Swap LED to light.

3. Disconnect all cables connected to the switch.

4. Loosen the two board retention screws that fasten the board to the enclosure.

5. Open the ejectors fully, rotating the handles outward until the board disengages from the midplane.

6. Slide the board evenly out of the enclosure.

7. Determine if you are going to replace the blade server.

|

Caution - Failure to cover all open slots with filler panels can negatively impact the cooling of the system. |

Following are the instructions for installing an AMC.

|

Caution - Before installing an AMC, read all cautions, warnings, and instructions presented earlier in this chapter. |

1. At the blade server, locate the AMC site where you want to install the AMC.

Depending on the blade server’s AMC site location, you might have to remove the blade server from the chassis. Some blade servers have compartments for AMCs that can only be accessed when the blade server is removed from the chassis.

Prevent possible damage to module components by verifying the proper site usage for your configuration. In most cases, electronic keying (e-Keying) prevents power on of a board into an incompatible site. However, as an extra precaution, know the site purpose.

2. Remove the filler panel, if necessary.

3. Obtain the AMC card from the ship kit.

| Note - Be sure to follow unpacking and handling instructions. See Section 1.2, Unpacking and Section 1.3, Handling AMCs. |

| Note - The illustration shows a sample of the top view for a 146GB AMC. If your AMC has a different capacity, the label shows it. |

4. Perform any card-specific hardware procedures, if necessary.

5. Prepare the AMC by fully opening its injector/ejector latches to the OUT position.

FIGURE 1-6 Opening the Injector/Ejector Latch

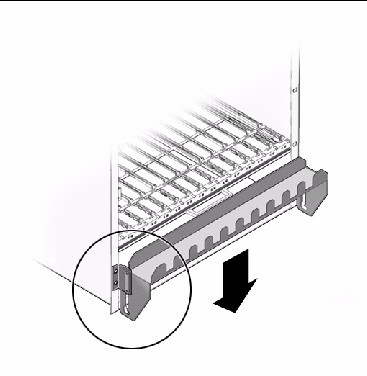

6. Carefully align the edges of the AMC with the guides in the appropriate site.

It might be helpful to look into the enclosure to verify correct alignment of the rails in the guides.

|

Caution - Do not force the AMC into the site. If it does not fit properly, check to ensure that you have the correct matching AMC for the switch. |

7. Keeping the AMC aligned in the guides, slide it in by pressing on the AMC faceplate until the AMC faceplate is flush with the blade server faceplate.

FIGURE 1-7 Inserting the AMC Into a Blade Server

8. Push the ejector latch in fully.

If system power is on and AMC is installed properly, the AMC board Hot-Swap LED lights up. The Hot-Swap LED blinks for several seconds, then goes off.

If the Hot-Swap LED does not go off after several seconds, push firmly on the injector/ejector handles to ensure that they are pushed in all the way.

|

Caution - Failure to fill all slots with AMCs or cover with filler panels can negatively impact the cooling of the system. |

9. Power on the system, if necessary.

Refer to your system manual for instructions on correctly powering on the system. After power is applied to the chassis, the internal MMC controller runs a self-test that runs for approximately 10 seconds. Upon a successful power up self-test, the blue Hot-Swap LED will blink and then turn off, indicating that the module has been placed in operation.

As shipped from the factory, the AMC.1-HDD SAS disk will not drive AMC channel ports, unless specifically enabled. You can individually enable or disable the ports using lsiutil, a command-line utility supplied by LSI Corporation, and distributed as part of the software driver distribution. Changes are stored in 32K x 8-bit NVSRAM, located on the module.

|

|

The “-p 1” selects the controller chip. If the AMC.1-HDD SAS disk is the only LSI controller chip present in the system then the default is controller 1. If there are other LSI controller chips present in the system, then the user has to determine the proper controller number.

|

|

Copyright © 2010, Oracle and/or its affiliates. All rights reserved.