Understanding Serial Genealogy

Understanding Serial Genealogy

This chapter provides an overview of serial genealogy in PeopleSoft Manufacturing and discusses how to:

Set up items to be traced by serial genealogy.

Associate assembly items and components.

Disassociate assembly items and components.

Maintain production being traced by serial genealogy.

Review serial genealogy information.

Make serial association using third-party systems.

Make serial associations using the batch process.

Generate serial ID labels.

Generate serial genealogy exception reports.

Understanding Serial Genealogy

Understanding Serial Genealogy

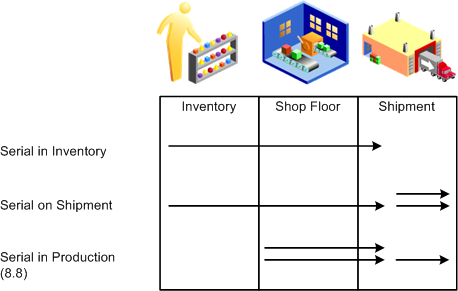

This diagram illustrates PeopleSoft and serial processing prior to Release 8.9

Serial processing prior to Release 8.9

With PeopleSoft Manufacturing, you can trace the location and constituent components of finished goods items and trace source and usage of component parts during the production process.

Serial genealogy tracks the source and destination of any serialized item. A serialized item may be used in a serialized assembly, scrapped, used in a higher level serialized assembly that is then shipped to a customer.

Serial IDs may be associated with the production IDs at any time during the manufacturing process.

For rework or teardown production IDs, you do not manually associate serial IDs to the assembly. The serial association occurs when you issue the assembly that is to be reworked or torn down through the picking process or kit issues.

In addition to associating a serial ID with the assembly item, you can associate component serial IDs with an assembly serial ID.

You can correct errors by disassociating the serial ID from the assembly or disassociating the component from the assembly serial ID.

In addition, we provide an inquiry that displays the genealogy of a serialized item through multiple levels of BOMs. This inquiry also displays the transaction information associated with the serialized item.

Note. Serial genealogy is tracked with single output production orders (IDs) only.

Serial genealogy is not tracked on:

Production schedules.

Production IDs with multiple outputs such as co-products or by-products.

Components with an quantity code of per order.

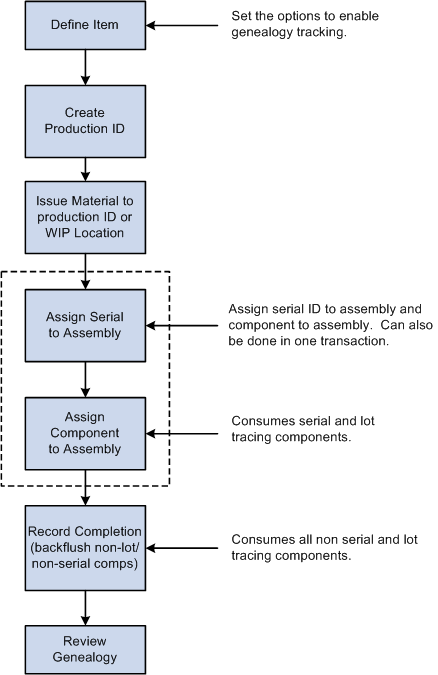

This diagram illustrates the serial genealogy process flow from setting the options on the item definition, to creating the production ID, issuing material, assigning serial IDs to assembly, assigning components to assembly, recording completions, and reviewing genealogy:

Serial Genealogy Process Flow

See Also

Maintaining Production Orders and Production Schedules

Issuing Material to Production

Completing Operations and Recording Scrap

Recording Completions and Scrap Using Electronic Data Collection

Setting Up Items to be Traced by Serial

Genealogy

Setting Up Items to be Traced by Serial

Genealogy

This section outlines the steps necessary to use serial genealogy:

Define and approve the item that will use serial genealogy using the Define Items - Inventory: Tracking Description page.

Set the appropriate serial tracking options.

Create a BOM and add the serial genealogy item using the Maintain BOMs and Revisions - Manufacturing BOMs: Summary page.

Create a production ID for the item to be produced using the Production ID Maintenance page.

Issue material to production using the various material issue processes.

Associate the serial ID to the assembly using the Assembly Serial page.

Associate the component serial ID or lot ID to the assembly using the Component Serial page.

Review the association by accessing the Genealogy Search (review) page.

Use the Maintain Serial Genealogy component to maintain or associate additional serial IDs.

Complete production using the Record Completions and Scrap component.

Note. You can associate a serial ID to an assembly at any time during the manufacturing process.

PeopleSoft Manufacturing enables you to track serial IDs by providing various options to determine the exact amount of control that you need.

Serial control indicates that you want to track the serial ID for each material movement transaction:

Ship Serial: Indicates that you want to track the serial ID when you ship an item.

Serial in Production: Indicates if you want to trace the genealogy of the assembly item during production.

Trace Usage: Indicates if you want to trace the component as it is used in a specific serial assembly.

The combination of these options determines the level of serial control.

See Also

Completing Operations and Recording Scrap

Page Used to Set Up Items to be Traced by

Serial Genealogy

Page Used to Set Up Items to be Traced by

Serial Genealogy|

Page Name |

Definition Name |

Navigation |

Usage |

|

INV_ITEMS_DEFIN2 |

Items, Define Items and Attributes, Define Item, Inventory, Tracking Description |

Set serial genealogy options to enable genealogy tracing. |

Defining Items Using Serial Genealogy

Defining Items Using Serial Genealogy

Access the Inventory - Tracking Description page (Items, Define Items and Attributes, Define Item, Inventory, Tracking Description).

Item Tracking

|

Select this option if you want to track the key serial and lot components that make up this assembly item. You will assign a serial ID to the item during the manufacturing process. You will also identify serial and lot components that are used to produce this item. This field can be used with and without the serial control option. If you do select serial control, then you will enter the serial ID for all material movement transactions. If you do not select the serial control option, then the system tracks the serial ID during the production process. This means that you assign a serial ID to the item during production and associate serial and lot components to this serial assembly. During completions you'll complete the serial ID to inventory. Note. Typically, if you select Serial in Production, either Serial Control or Ship Serial will also be enabled. If you select serial in production and not serial control, during subsequent inventory movements of this item, you will not need to enter the serial ID. |

|

|

This option is used for component items and enables associating the component's serial or lot ID with a higher-level assembly item whose serial in production option is selected. Values include:

Similar to serial in production, trace usage can be used in conjunction with the Serial Control option. If Serial Control option is selected, then the serial ID will be identified in inventory, and this serial ID remains with the item throughout the entire manufacturing process. If serial control is not selected, then the serial ID will not be identified in inventory but a serial ID will be specified when the item is associated with a serial assembly. This allows tracking the genealogy without requiring the need to track the serial ID in inventory. |

Note. Typically, if you select the trace usage option of Serial or Lot, the assembly items that this item is used on is set to Serial in Production.

Note. If you change any of these values, it will have an effect on new production. Any existing production will retain the serial in production value at the time that the production ID was created. Components will retain the values at the time the component list is created.

See Also

Associating Assembly Items and Components

Associating Assembly Items and Components

You can associate assembly items to serial IDs and components to serialized assemblies by using the Assembly Serial page. You can access this page from the Production Control or SCM Integrations navigations.

This section discusses how to:

Associate assembly items to serial IDs.

Associate components to serialized assemblies.

Pages Used to Associate Assembly Items and

Components

Pages Used to Associate Assembly Items and

Components|

Page Name |

Definition Name |

Navigation |

Usage |

|

BCT_MG_PRDN |

|

Associate serial IDs with assembly items of a production ID. Use Transaction Code 800 — Associate Assembly to associate a serial ID with a production ID. |

|

|

BCT_MG_USAG |

|

Associate serial or lot components with an assembly serial (Transaction Code 802). Can also be used to associate a serial ID with an assembly and associate the component serial ID or lot ID with that serial assembly (Transaction Code 804). |

Associating Assemblies to Serial IDs

Associating Assemblies to Serial IDs

Access the Assembly Serial page (Production Control, Process Production, Production Genealogy, Record Assembly Serial).

Use this page to associate a serial ID to the production ID.

Note. The Serial in Production option must be selected for the production ID.

To associate a serial ID with an assembly using Transaction Code 800 - Associate Assembly:

Select the Production ID.

Enter a Quantity. The Serial ID group populates with the number of lines based on the quantity entered.

Enter a Serial ID to associate with the production ID.

Upon saving this page, any errors, such as the serial ID may have already been associated with a different production ID, display in Error Messages.

Note. If you made the association using the Production Control navigation, the transaction is processed upon save. However, if you used the SCM Integrations navigation, the transaction will not be processed until you run the Process Serial Association process.

Associating Components to Serialized Assemblies

Associating Components to Serialized Assemblies

Access the Component Serial page (Production Control, Process Production, Production Genealogy, Record Component Serial).

Associate serial or lot components to a serial assembly by using Transaction Code 0802 - Associate Component.

If you're associating both assemblies and components, use Transaction Code 0804 - Associate Assembly & Component.

|

Production ID and Serial ID |

Enter values. |

|

Associate Assembly Serial |

If you're using Transaction Code 804, this check box will be automatically selected. When selected, the system associates the serial ID with the production ID. Once the first serial association is saved, this check box will be deselected so you can associate additional component serial IDs to the serial assembly. If you want to associate serial IDs to assemblies and component serials, then you should select this check box. |

|

Component ID |

Enter the component that you're associating or disassociating from the production ID. |

|

Op Seq, Orig Comp ID and Per |

You do not have to enter values for these fields. The system will populate them. If the component ID exists at multiple operation sequences or the component is a substitute item you will need to specify this information in order to identify the exact component you are associating or disassociating. |

|

Quantity |

Enter the number of components that you are associating or disassociating. |

|

Serial ID |

The Serial ID group populates the number of lines based on the quantity entered. Enter or select the appropriate serial ID number. |

|

Lot ID |

Enter or select the appropriate lot ID |

|

Error Messages |

View any errors associated with the component association. |

Note. Upon Save, the production ID field is not deselected.

You can add (associate) another component.

If you made the association using the Production Control navigation,

the transaction is processed upon save. However, if you used the SCM Integrations

navigation, the transaction will not be processed until you run the Process

Serial Association process.

In addition, issue and replenish components are consumed from the WIP

location upon association. Kit components are associated as they have already

been consumed on the production ID.

See Making Serial Associations Using the Batch Process.

Disassociating Assemblies and Components

Disassociating Assemblies and Components

Use the Assembly Serial and Component Serial pages to disassociate serial IDs from assemblies, and to remove components from serialized assemblies. Access these pages from the Production Control or SCM Integrations navigations.

This section discusses how to:

Disassociate assemblies from serial IDs.

Disassociate components from serialized assemblies.

Pages Used to Disassociate Assemblies and

Components

Pages Used to Disassociate Assemblies and

Components|

Page Name |

Definition Name |

Navigation |

Usage |

|

BCT_MG_PRDN |

|

Disassociate serial IDs with assembly items of a production ID. Use Transaction Code 0801- Disassociate Assembly to disassociate a serial ID from the assembly. |

|

|

BCT_MG_USAG |

|

Disassociate serial or lot components with an assembly serial. |

Disassociating Assemblies from Serial IDs

Disassociating Assemblies from Serial IDs

Access the Assembly Serial page (Production Control, Process Production, Production Genealogy, Record Assembly Serial).

To disassociate a serial ID with an assembly by using Transaction Code 801 - Disassociate Assembly:

Select the Production ID.

Enter a Quantity. The Serial ID group populates with the number of lines based on the quantity entered.

Enter a Serial ID to disassociate from the production ID.

Upon saving this page, any errors, such as the serial ID may have already been associated with a different production ID, display in Error Messages.

Note. If you made the disassociation using the Production Control navigation, the transaction is processed upon save. However, if you used the SCM Integrations navigation, the transaction will not be processed until you run the Process Serial Association process.

Disassociating Components from Serialized

Assemblies

Disassociating Components from Serialized

Assemblies

Access the Component Serial page (Production Control, Process Production, Production Genealogy, Record Component Serial).

To disassociate a component from a serial assembly, use Transaction Code 803 - Disassociate Component.

Select the Production ID (serial assembly).

Select a Serial ID to disassociate from the production ID.

Select the Component ID to be disassociated.

Enter a Quantity of the component to be disassociated.

Upon saving this page, any errors, such as the serial ID may have already been associated with a different production ID, display in Error Messages.

Note. If you made the disassociation using the Production Control navigation, the transaction is processed upon save. However, if you used the SCM Integrations navigation, the transaction will not be processed until you run the Process Serial Association process.

Maintaining Production Being Traced by Serial

Genealogy

Maintaining Production Being Traced by Serial

GenealogyThis section discusses how to maintain production being traced with serial genealogy.

Page Used to Maintain Production Being Traced

by Serial Genealogy

Page Used to Maintain Production Being Traced

by Serial Genealogy|

Page Name |

Definition Name |

Navigation |

Usage |

|

SF_TRACE_U_SRCH |

Production Control, Process Production, Production Genealogy, Maintain Serial Genealogy |

Select the production ID to which you want to do an association or disassociation. |

|

|

SF_TRC_MAINT |

Production Control, Process Production, Production Genealogy, Maintain Serial Genealogy |

View the parent serial ID information. |

|

|

BCT_MG_PIK |

SCM Integrations, Create Transactions, Manufacturing, Production Picking |

For rework or teardown production IDs, enter the serial ID for the assembly items being reworked or torn down. The system associates the serial ID to the production ID. |

|

|

SF_KIT_ISSUE_EXPR BCT_MG_MIS |

|

For rework or teardown production IDs, enter the serial ID for the assembly items being reworked or torn down. The system associates the serial ID to the production ID. |

|

|

SF_PICK_TRANS |

Production Control, Process Production, Issue Materials, Review Plan |

For rework or teardown production IDs, enter the serial ID of the assembly items being reworked or torn down. The system associates the serial ID to the production ID. |

|

|

SF_COMPL_ID BCT_MG_CPL |

|

Associate assembly serial IDs if the serial that is being completed and has not already associated. See Completing Operations and Recording Scrap, Recording Completions and Scrap Using Electronic Data Collection. |

Reviewing Serial Genealogy Information

Reviewing Serial Genealogy Information

This section discusses how to:

Enter genealogy search review criteria.

Review serial genealogy information.

Review traceability information.

Pages Used to Review Serial Genealogy Information

Pages Used to Review Serial Genealogy Information|

Page Name |

Definition Name |

Navigation |

Usage |

|

SF_TRC_SER_INQ1 |

Production Control, Process Production, Production Genealogy, Review Serial Genealogy |

Enter selection criteria for serial genealogy inquiry. Use the Review Serial Genealogy to view the genealogy of an item/serial. You can also view where the item/serial currently is at, such as which higher level assembly item it has been used in or to which customer it has been shipped. |

|

|

SF_TRC_SER_INQ2 |

Enter information on the Genealogy Search (review) page and click the Search button. |

Displays genealogy information for the item (serial ID) specified in the search criteria. Displays where used and genealogy information. |

|

|

SF_TRC_SER_INQ3 |

Enter information on the Genealogy Search (review) page. You must select Transaction Information as a display option on the Genealogy Search page. Click the Search button. |

View transaction information for the item/serial ID specified in the search criteria. Information is displayed in a grid format. |

|

|

SF_TRC_SER_INQ4 |

Enter information on the Genealogy Search (review) page and click the Search button. Click a serial ID or lot ID link. |

View transaction information associated with the specific serial or lot ID. Information is displayed in a pop up window. |

Entering Genealogy Search Review Criteria

Entering Genealogy Search Review Criteria

Access the Genealogy Search (review) page (Production Control, Process Production, Production Genealogy, Review Serial Genealogy).

|

Item ID and Serial ID |

Enter values. |

Display Options

Select any of these display options:

|

Levels |

Enter the number of levels that you want to display. The default is 99. |

|

Non-Indented or Indented |

|

|

Where Used |

Select this check box if you want to go up the genealogy tree to display where the serial ID is used. This check box is not limited to just production where used. Information relating to which customer the item has been shipped to will also display. |

|

Genealogy |

Select if you want to see the children of the serial selected. |

|

Transaction Information |

Select if you'd like to view the transaction history for the item. Note. You must select this option to access the Genealogy with Traceability page. |

|

Last Transaction |

Select if you want to see the last transaction that has occurred for this item or serial ID. For example, if the last transaction is a shipment transaction, the customer to whom this serial ID has been shipped displays. |

Reviewing Serial Genealogy Information

Reviewing Serial Genealogy Information

Access the Genealogy (review) page (Enter information on the Genealogy Search (review) page and click the Search button).

Item Type

|

Serial Control, Lot Control, Shipping Serial Control, Serial in Prdn, and Trace Usage |

These item attributes are display only and are the default values from the Define Items component. |

Where Used Components

|

Serial ID |

Click to access the transaction information for the item. |

|

Lot ID |

Click to access the transaction information for the item. |

Transaction Information Tabs

Access any of these Transaction Information tabs:

|

Common |

View general information such as date and time of transactions, such as production association, or production disassociation and quantities of the items. |

|

Production |

View production information such as Prdn ID, Prdn Type, production Area, and Prdn ID split information such as To Prdn ID and To Prdn Area. |

|

Shipment |

View shipping information such as Ship To ID, Customer Name, Order No., Ship to, and RMA Number. |

|

Inventory |

View inventory-related information such as the Storage Area where the item is stored. |

|

Purchasing |

View purchasing-related information such as Order No, Order Line, Vendor ID, Vendor Name, and Return to Vendor ID. |

Reviewing Traceability Information

Reviewing Traceability Information

Access the Genealogy with Traceability page (Enter information on the Genealogy Search (review) page. You must select Transaction Information as a display option on the Genealogy Search page. Click the Search button).

This page appears when you select the Transaction Information display option on the Genealogy Search page.

Making Serial Associations Using Third-Party

Systems

Making Serial Associations Using Third-Party

Systems

This section discusses how to make serial associations for production using third-party systems such as electronic data collection or a MES.

PeopleSoft Manufacturing uses the Production Serial Association EIP to import production data that has been associated with serial genealogy by an external system.

See Also

Getting Started with PeopleSoft Manufacturing

Making Serial Associations Using the Batch

Process

Making Serial Associations Using the Batch

Process

You can use the Run Serial Associations (SF_TRC) batch process to associate or disassociate production from serial genealogy. You'll run this batch process if you associated or disassociated production using the SCM Integrations navigation. You will also need to run this process if you have used the Production Serial Association EIP to load associate or disassociate transactions.

Page Used to Make Serial Associations Using

the Batch Process

Page Used to Make Serial Associations Using

the Batch Process|

Page Name |

Definition Name |

Navigation |

Usage |

|

RUN_SF_TRC |

|

Run the batch process for a specific business unit or all business units. You can also run the process based on a specific EIP, range of EIPs or all EIPs. Process serial associations that were loaded through EIPs or through the data collection pages under the SCM Integrations navigation. EIPs can be sent from third-party systems such as a data collection system or a manufacturing execution system (MES). |

Generating Serial ID Labels

Generating Serial ID Labels

This section discusses how to generate bar code labels for serialized items.

Page Used to Generate Serial ID Labels

Page Used to Generate Serial ID Labels|

Page Name |

Definition Name |

Navigation |

Usage |

|

RUN_INS6035 |

SCM Integrations, Barcode Labels, Serial Label |

Create barcoded serial labels for serialized items. |

Generating Serial Genealogy Exception Reports

Generating Serial Genealogy Exception Reports

You can generate serial genealogy exception reports that list those production IDs that have association inconsistencies.

This section discusses how to generate exception reports for production being traced by serial genealogy, and how to correct the exception messages that may occur.

Page Used to Generate Serial Genealogy Exception

Reports

Page Used to Generate Serial Genealogy Exception

Reports|

Page Name |

Definition Name |

Navigation |

Usage |

|

RUN_SF_TRC001 |

Production Control, Process Production, Production Genealogy, Genealogy Exception Report |

Generate a report that lists those production IDs that have association inconsistencies. |

Reviewing Genealogy Exception Report Messages

Reviewing Genealogy Exception Report Messages

This table discusses the exception messages that you may encounter when you generate a Genealogy Exception Report.

Genealogy Report Exception Messages

|

Exception Message |

Warning Description |

|

Assembly Exceptions Serial IDs not associated with Assembly Scrap |

There is assembly scrap that does not have a serial ID associated with it. If you want to associate serial IDs to the scrap, you will need to reverse the scrap and then rescrap. |

|

Serial IDs associated > Completed + Scrap |

There are serial IDs associated with the production ID that have not been completed or scrapped. You should verify that the serial IDs are still in production |

|

Component serial/lot association rows do not exist |

There are completed serial assemblies that do not have any serial or lot components associated. You may need to enter the component association transactions. |

|

Component Exceptions Component Issue <> Trace Usage |

You have consumed more serial IDs than have been associated with an assembly. You should verify the correct component associations have been recorded. |

|

Component serial/lot association rows do not exist |

You have consumed quantity but no component association rows have been recorded. You should verify the correct component associations have been recorded. |

|

Comp List qty per <> Sum of Trace Issue Qty |

You have associated more or less quantity than what is scheduled. You should verify the correct component associations have been recorded. |

See Also

SFS8000 - Genealogy Exception Report